Vibration isolator

A vibration isolation and cooling device technology, which is applied in the direction of non-rotational vibration suppression, can solve the problems of low vibration isolation capacity, small displacement, low frequency response of actuators, etc., and achieve high vibration isolation capacity and good vibration isolation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

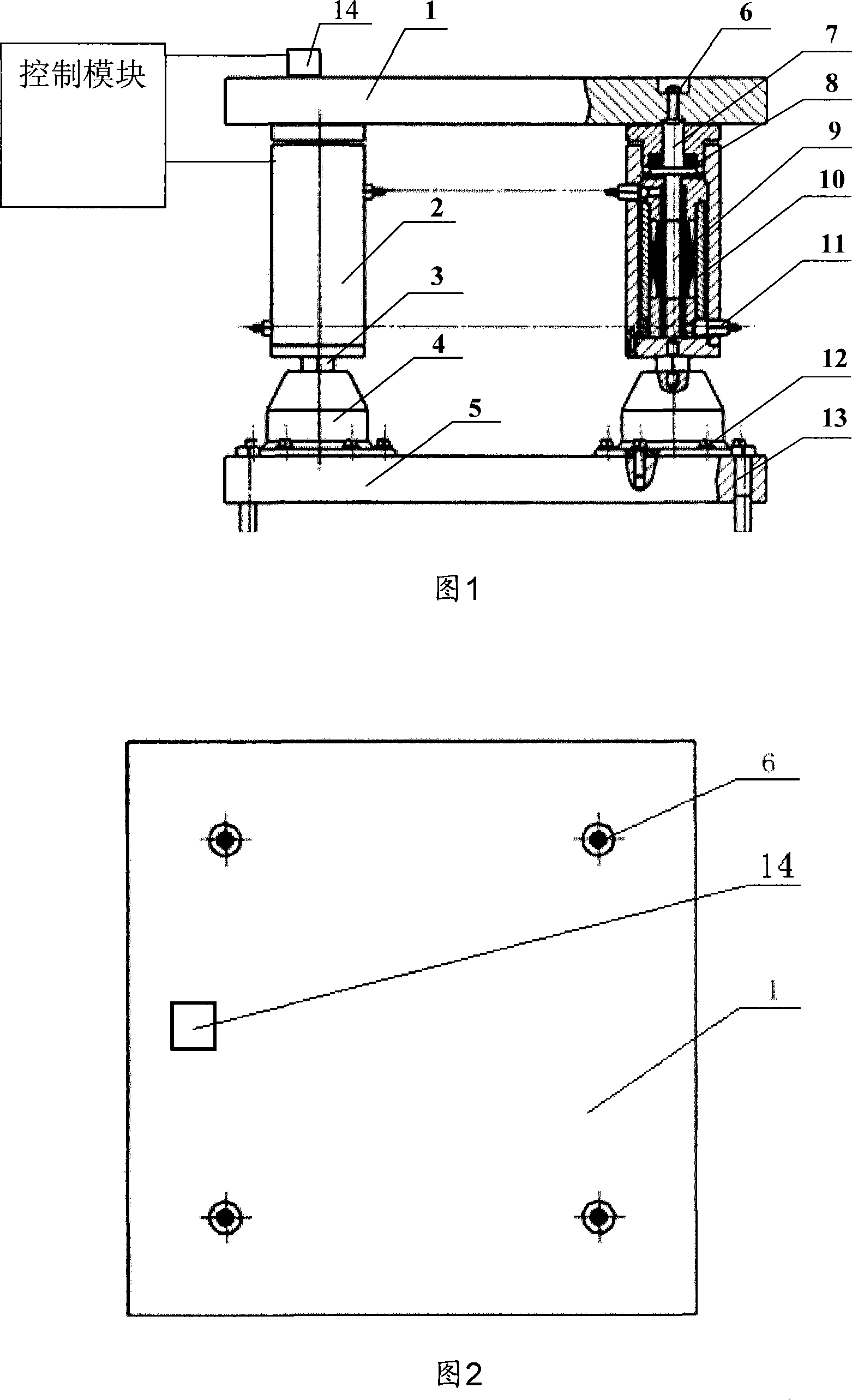

[0017] The preferred embodiment of the vibration isolation device of the present invention is shown in Fig. 1 and Fig. 2, including a working platform 1, a support platform 5, and a control module, which may be a computer, a single-chip microcomputer, or the like.

[0018] A plurality of magnetostrictive actuators 2 are arranged between the working platform 1 and the supporting platform 5, and an acceleration sensor 14 is arranged on the working platform 1, and the acceleration sensor 14 detects the vibration signal of the working platform 1, and transmits the signal to the The control module, the control module controls the action of the magnetostrictive actuator 2 according to the signal to counteract the vibration of the working platform 1 .

[0019] Four magnetostrictive actuators 2 may be arranged between the working platform 1 and the supporting platform 5, which are respectively arranged at the four corners of the vibration isolation device. It is also possible to set 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com