Secondary optical lens

A secondary optical lens and light emitting surface technology, applied in the field of LED lighting, can solve the problems of difficult control of the shape of the light spot and low light output rate of the secondary optical processing, so as to reduce the loss of secondary refraction, reduce the loss of stray light, and easily The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

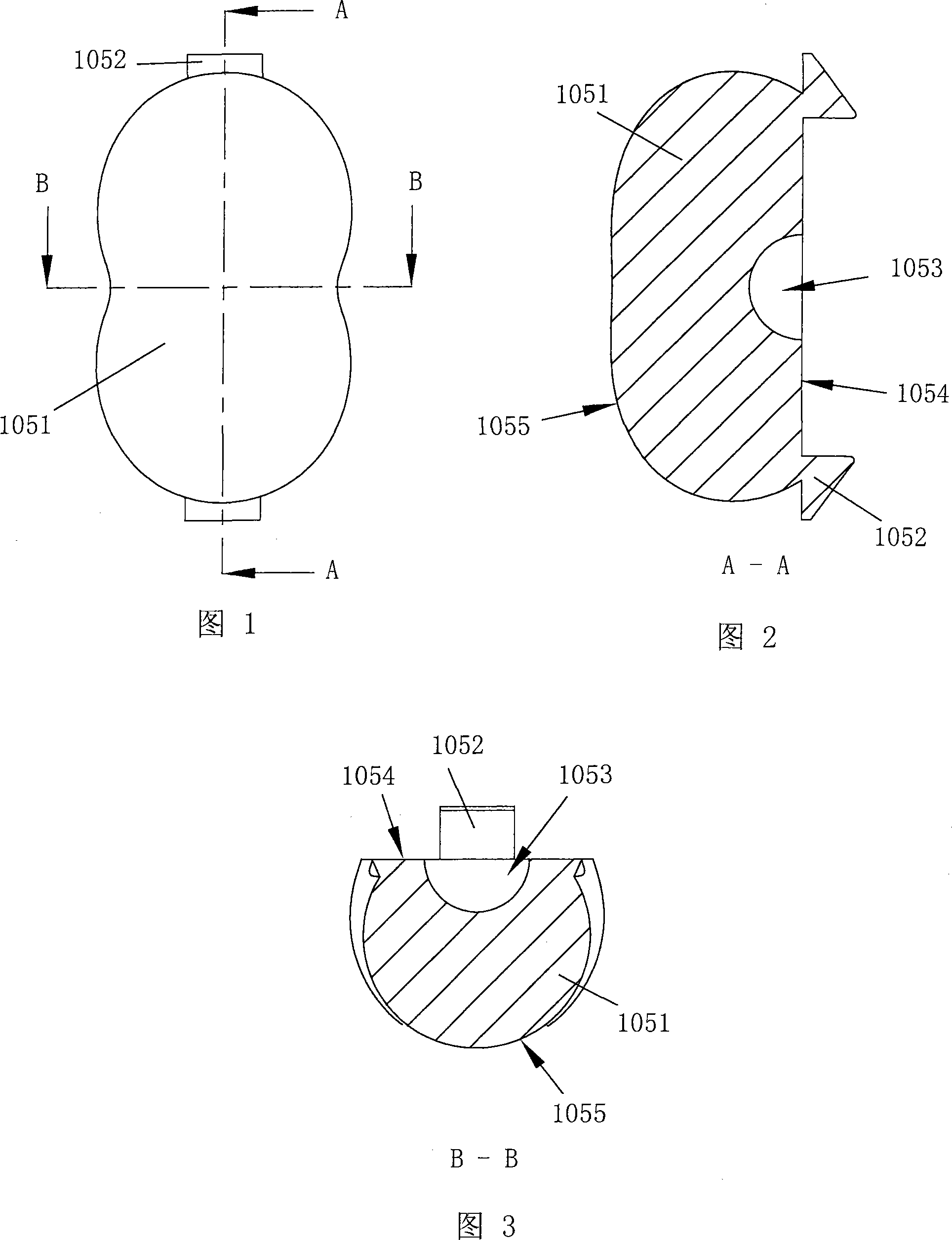

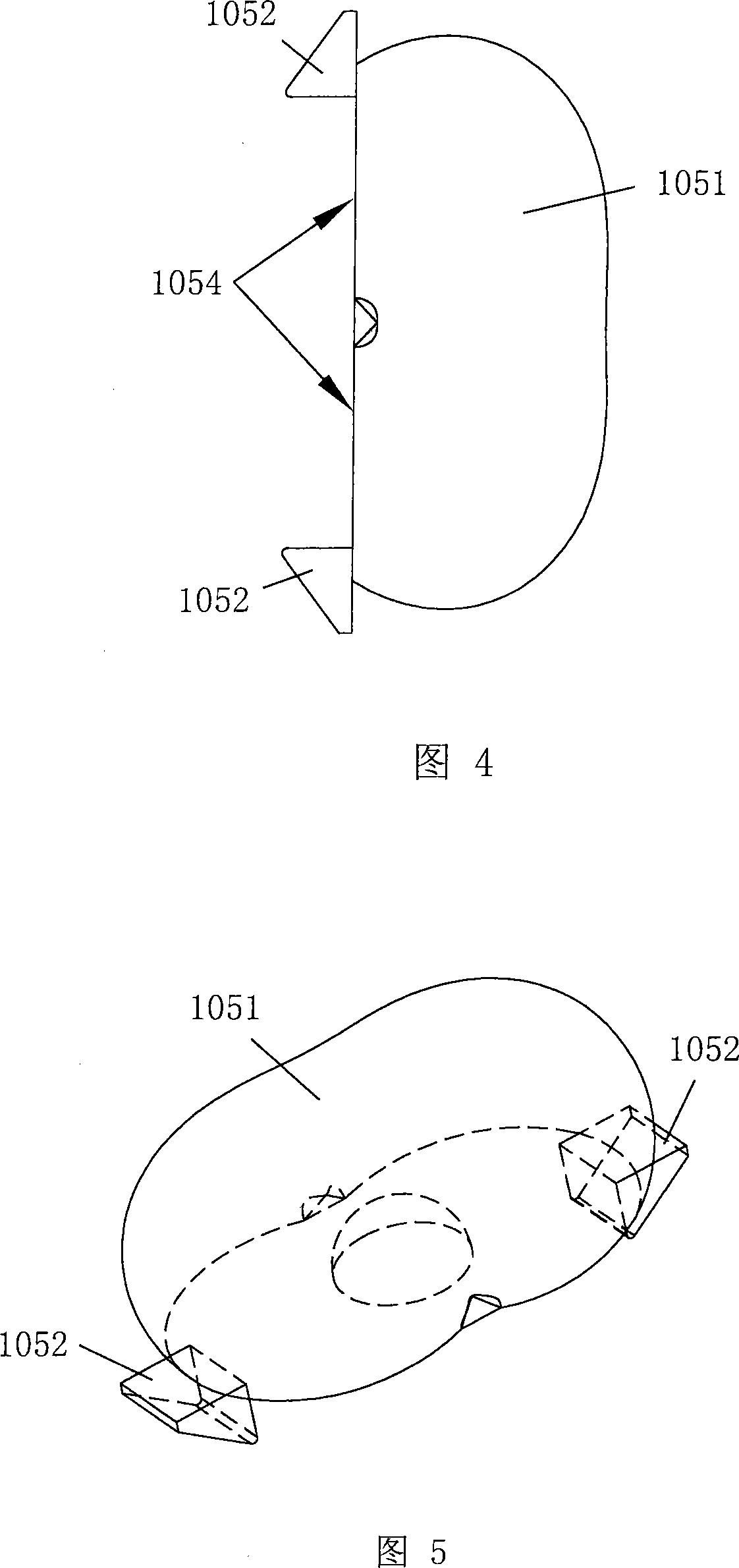

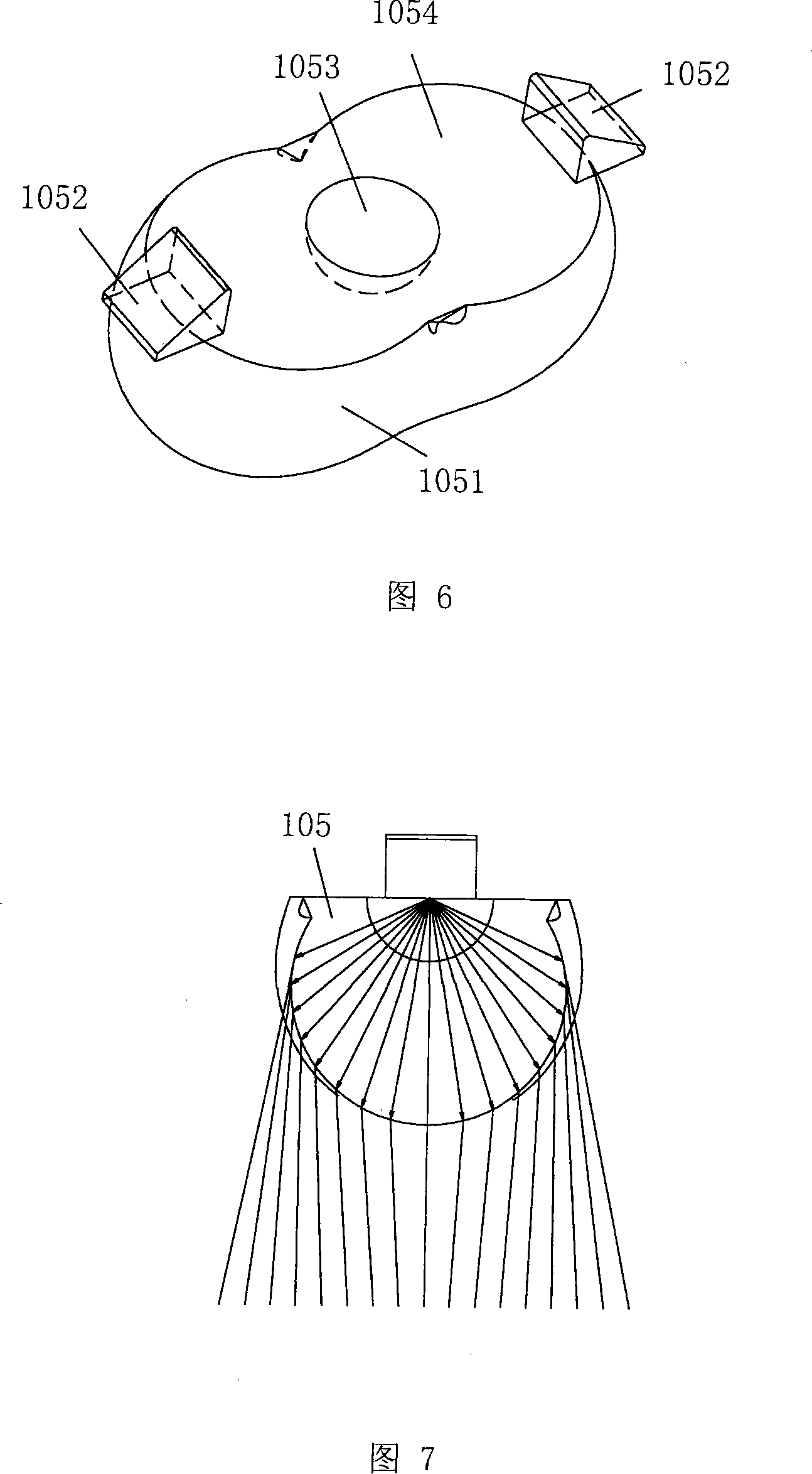

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings. With reference to Fig. 1 to Fig. 6, the first embodiment of the present utility model is a kind of secondary optical lens 105, has a base surface 1054, and base surface 1054 is a plane; The transition surface between the two partial spherical surfaces; the light-emitting surface 1055 intersects with the base surface 1054 to define the outline of the base surface 1054; the center of the base surface 1054 is provided with a light-incident surface 1053, which is a concave surface; the base surface 1054, the light incident surface 1053, and the light exit surface 1055 jointly define the body 1051 of the secondary optical lens 105; the secondary optical lens 105 also includes a pair of hooks 1052 arranged on the base surface 104 of the body, and the pair of hooks 1052 are respectively arranged on The two longitudinal edges of the base surface 1054; the tip of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com