Vane cell pump

A vane pump and vane technology, which is applied in pumps, pump control, rotary piston pumps, etc., can solve the problems of high manufacturing cost and complex structure of pendulous slide valve pumps, and achieve the effect of simple manufacture and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] For a better understanding of the invention, reference is made to the entire content of DE 10 2005 048 602, the content of which is hereby incorporated by reference.

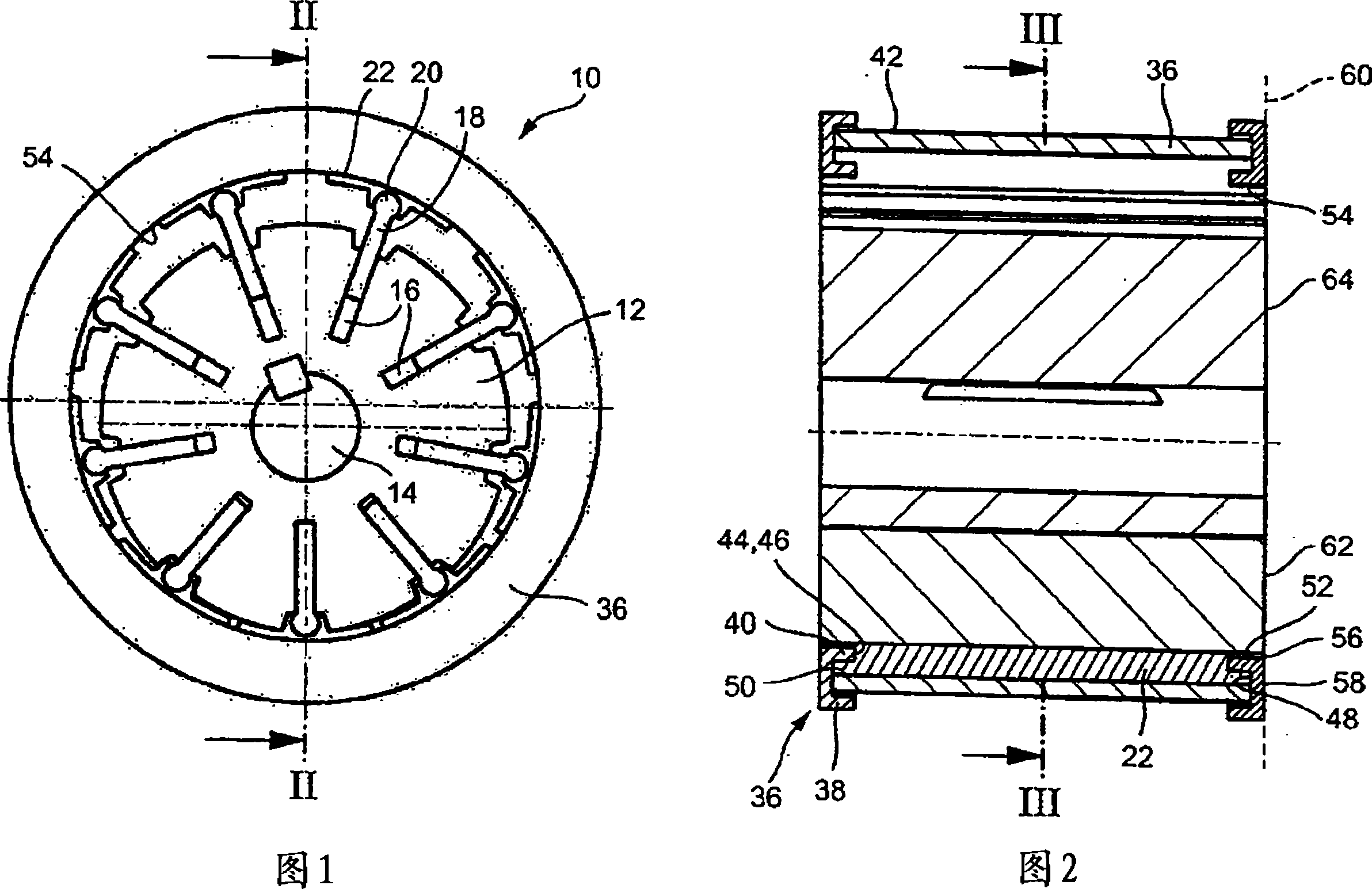

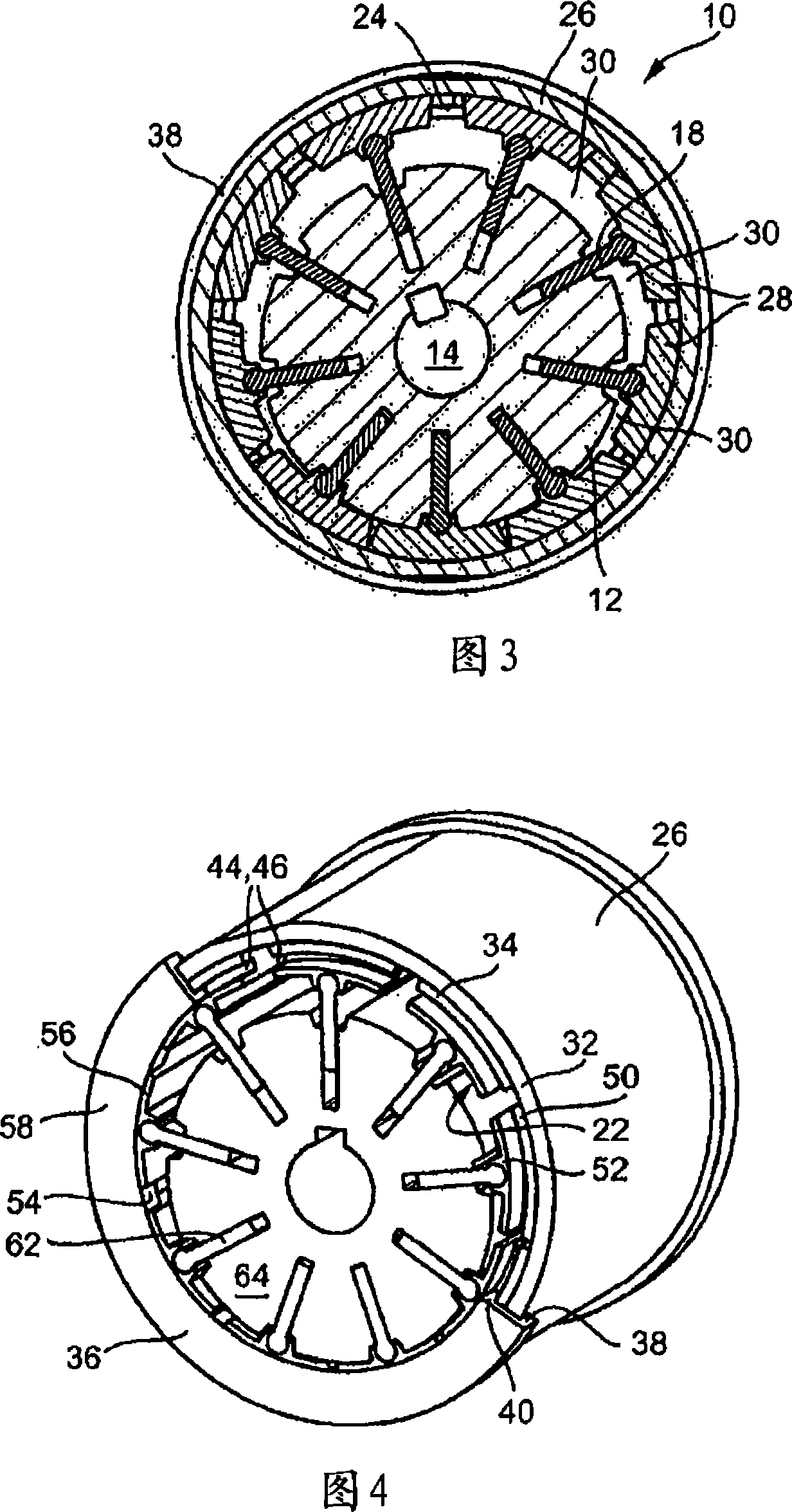

[0023] FIG. 1 shows a side view of a vane pump, generally designated 10 , having an inner rotor 12 driven by a drive shaft 14 . The inner rotor 12 has radial slots 16, and blades 18 are movably mounted in each radial slot 16 in the radial direction. The blade 18 has a thick outer end 20 to which a guide block 22 is pivotally mounted. As can be clearly seen in FIG. 3 , this guide block 22 rests on the inner peripheral surface 24 of the stator 26 . These guide blocks 22 form an outer rotor 28 which, together with the inner rotor 12 , rotates in the circumferential direction relative to the stator 26 . The blades 18, the inner rotor 12 and the guide block 22 together with the stator 26 form a working space 30, and when the inner rotor 12 rotates, the capacity of the working space expands and then shrinks. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com