Method for preparing globular crystal aluminium alloy semi-solid slurry material by low rotary speed transport pipe

A technology of semi-solid slurry and conveying pipe, which is applied in the field of semi-solid slurry of near-spherulite aluminum alloy prepared by low-speed conveying pipe, which can solve the problems of low efficiency, difficulty in billet handling, high electromagnetic stirring power, etc. Short, adaptable, and simple-to-equip effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

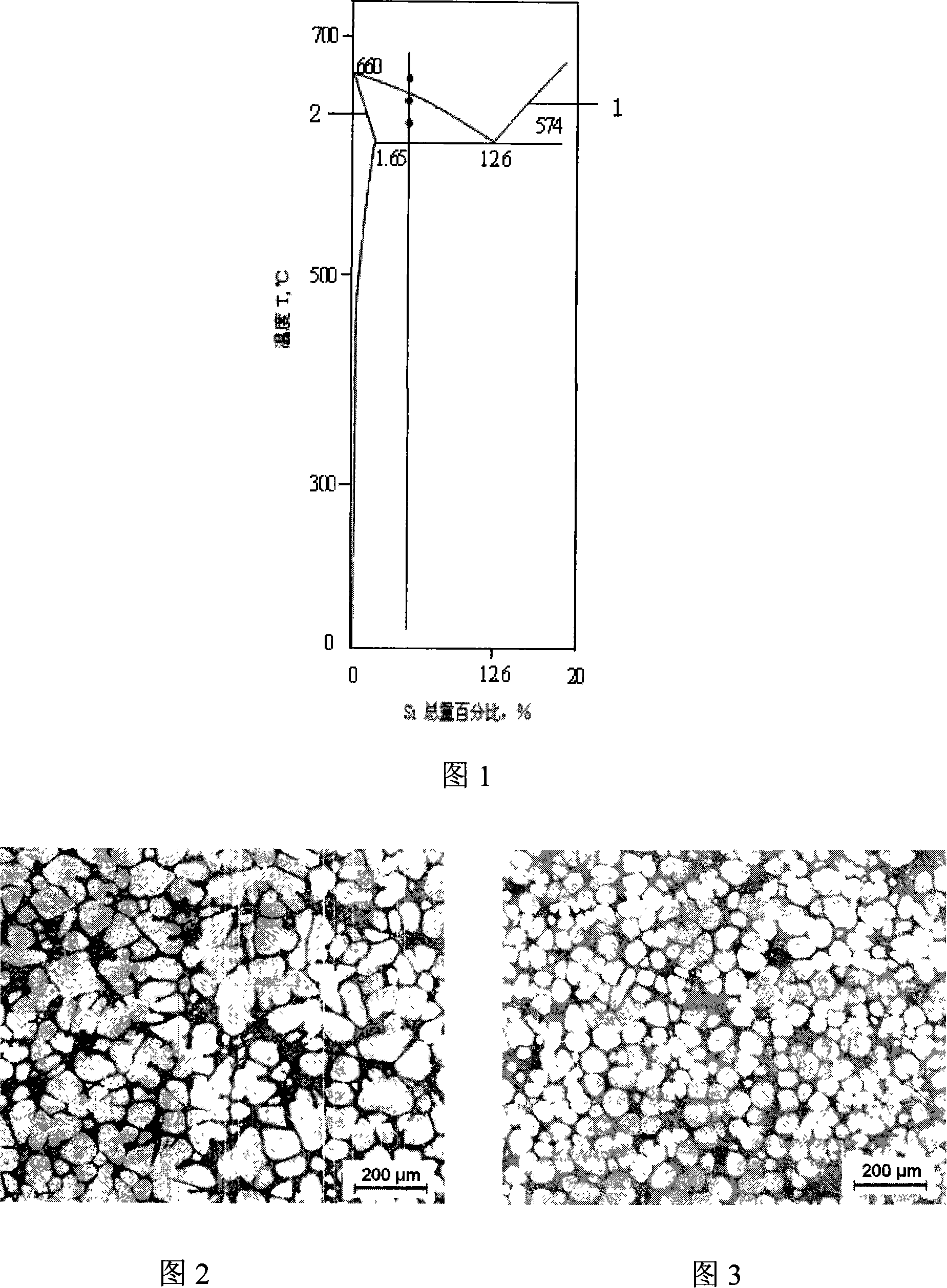

[0013] The specific implementation of the slurry preparation process of the present invention will be described below by taking the A356 alloy as an example. As shown in Figure 1, the chemical composition of the alloy is: Si-6.9%, Mg-0.35%, Fe-0.09%, Cu-0.01%, Mn-0.02%, and the rest is Al. The alloy has a liquidus temperature of 615°C and a solidus temperature of 574°C. During the whole pulping process, Ar gas is passed through the melting and holding furnace and the crystallization furnace to protect the aluminum alloy melt. The specific process is as follows:

[0014] (1) The example alloy was melted at a high temperature of 720°C in a melting and holding furnace, and refined for 1 hour; then the alloy melt was cooled to a pouring temperature of 655°C, and kept for 15 minutes to homogenize the temperature and chemical composition of the alloy melt.

[0015] (2) Low temperature pouring. When the alloy melt meets the process requirements, it is poured into the rotating conve...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap