Vertical rolling machine

A winder, vertical technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of increasing unloading time, troublesome operation, reducing production efficiency, etc., to reduce labor intensity, The unloading work is simple and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

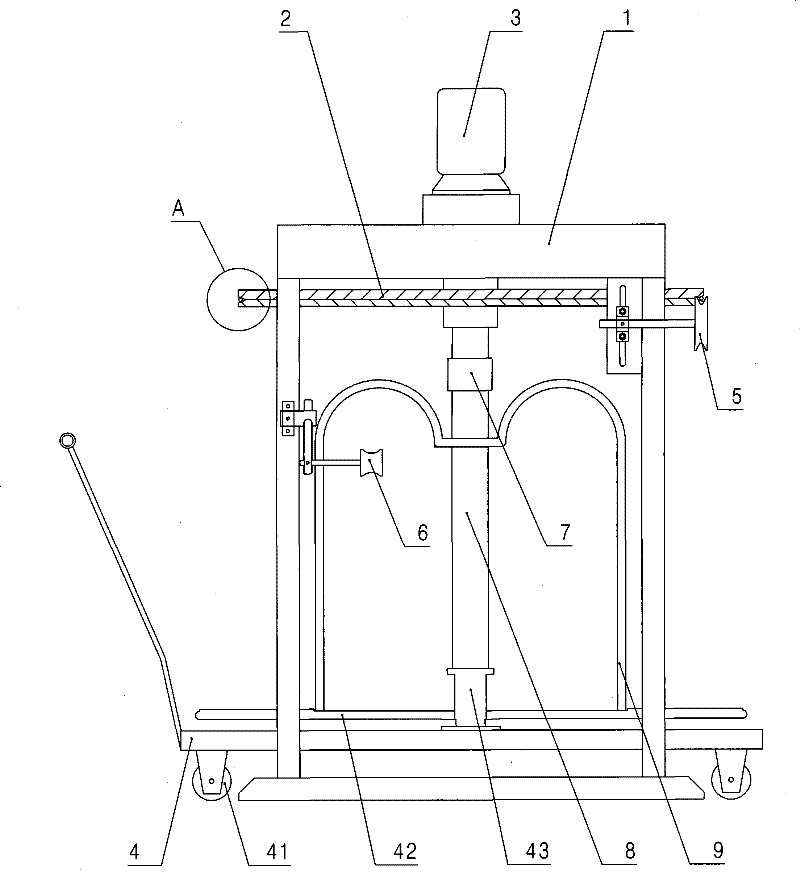

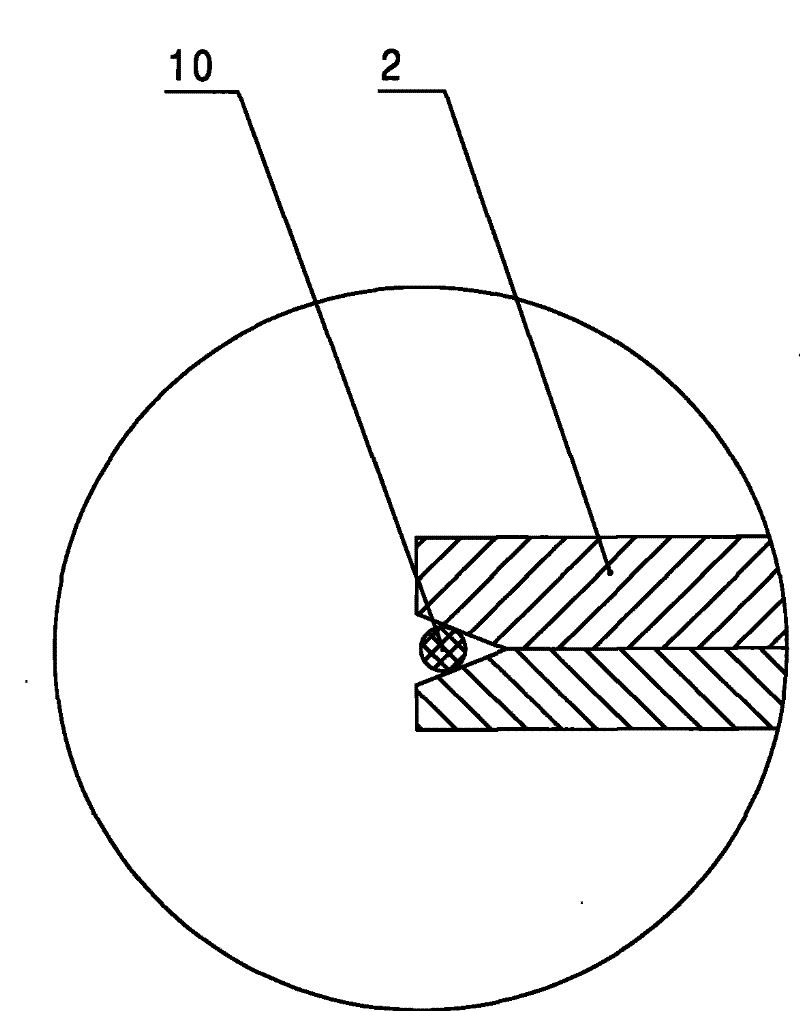

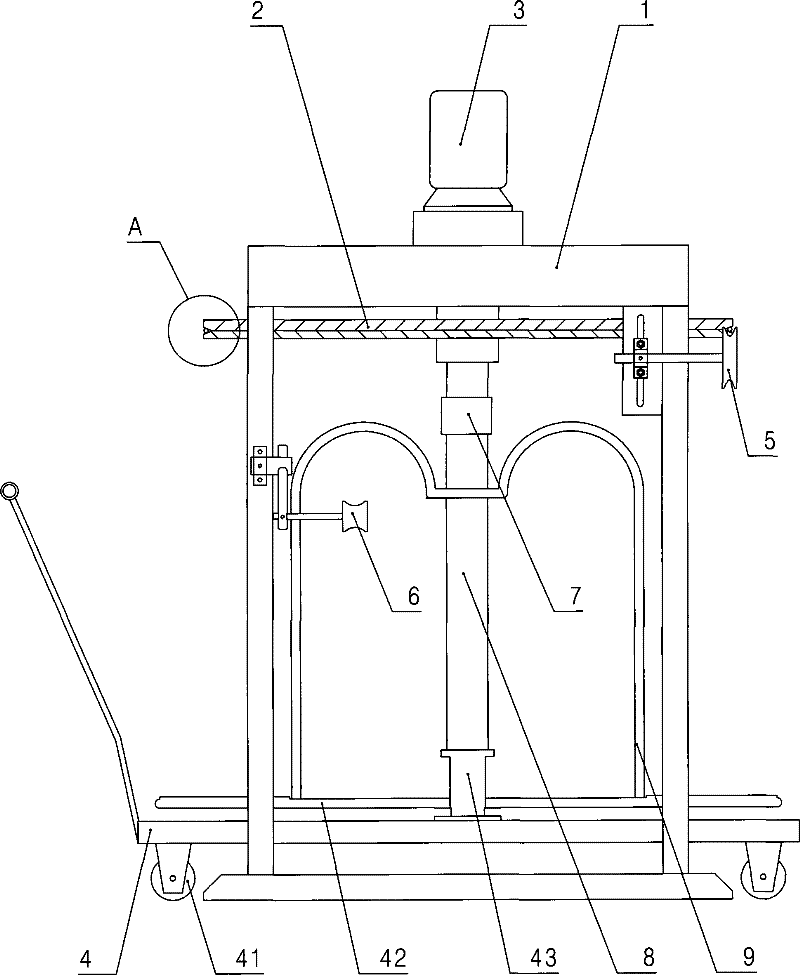

[0013] Such as figure 1 As shown, the vertical winder of the present invention includes: a frame 1, the top of the frame 1 is provided with an inverted driving device 3 mainly composed of a torque motor and a reducer, and the output shaft of the driving device 3 is a deceleration The output shaft of the machine is provided with a looper coupling 7, and the upper part of the frame 1 is movably provided with a traction disc 2 composed of upper and lower discs, and the circumferential surface of the traction disc 2 is provided with The "V"-shaped clamping groove enables the traction disc 2 to stably clamp various wires or pipes. The frame 1 is provided with an introduction wheel 5 for introducing wires or pipes next to the clamping groove. On the traction disc 2 The bottom of the reel 9 and the lead-out wheel 6 matched with the reel 9 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com