Intelligent rectifying kettle

A rectification kettle and distillation tower technology, applied in the field of intelligent rectification kettle, can solve the problems of waste, impurities easily polluting the working environment, inconvenient equipment support, etc., to achieve convenient fixing and installation work, and prevent environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

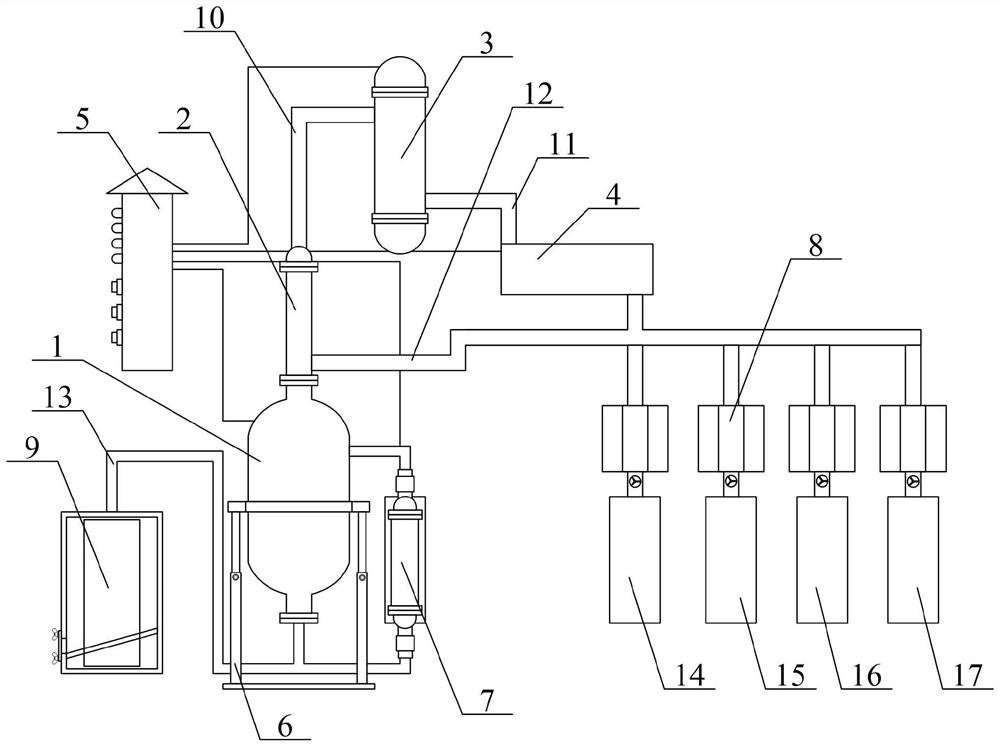

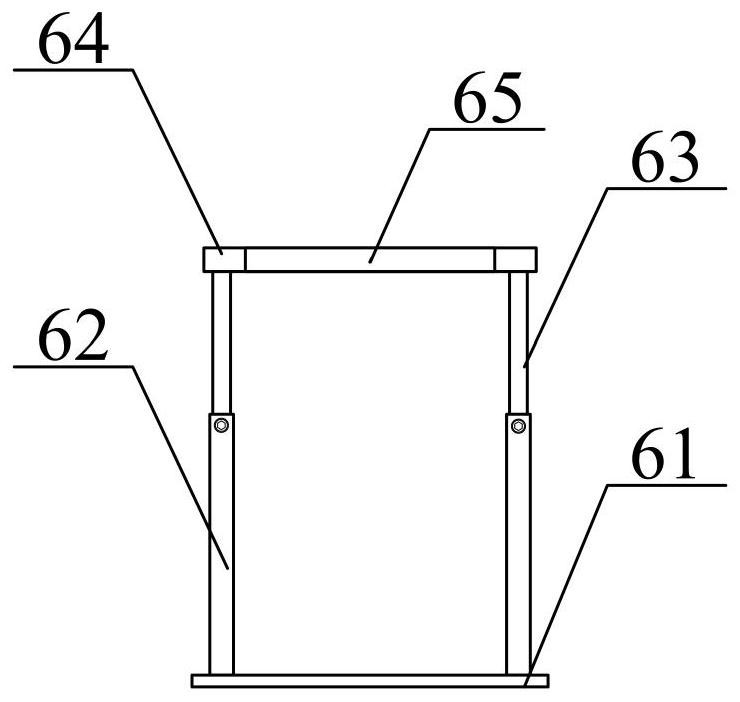

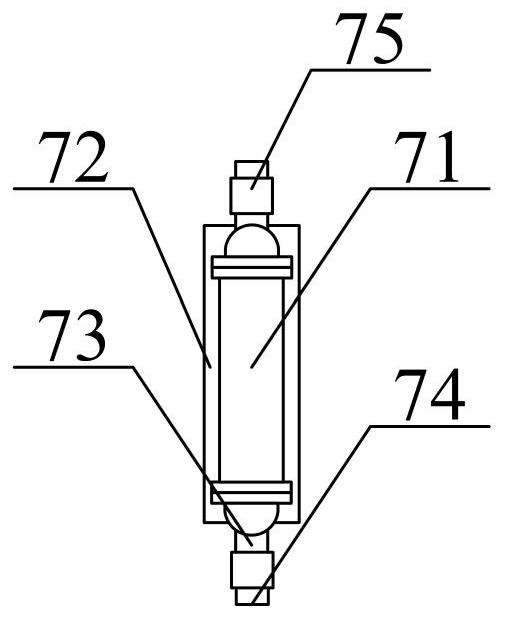

[0035] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, the intelligent rectification kettle includes a rectification tower body 1, a packed tower 2, a condenser 3, a phase separator 4, a control cabinet 5, an adjustable support seat structure 6, and a detachable maintenance heating barrel structure 7, which can be Observe the buffer shunt pipe structure 8, you can observe the discharge tank structure 9, the first delivery pipe 10, the second delivery pipe 11, the third delivery pipe 12, the fourth delivery pipe 13, the front reserve tank 14, the finished product tank 15, and the recovery tank 16 and a waste water tank 17, the packed tower 2 is bolted to the middle position of the upper end of the rectification tower body 1 and communicated; the lower end of the first delivery pipe 10 is screwed to the middle position of the upper end of the packed tower 2; The upper end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com