Method for increasing thin-sand-layer-filling soft clay foundation vacuum degree

A technology of vacuum degree and soft clay, applied in soil protection, infrastructure engineering, construction, etc., can solve problems affecting the effect of vacuum preloading reinforcement, affecting the effect of vacuum preloading, large pressure loss, etc., to reduce losses, Easy to make, the effect of improving the vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

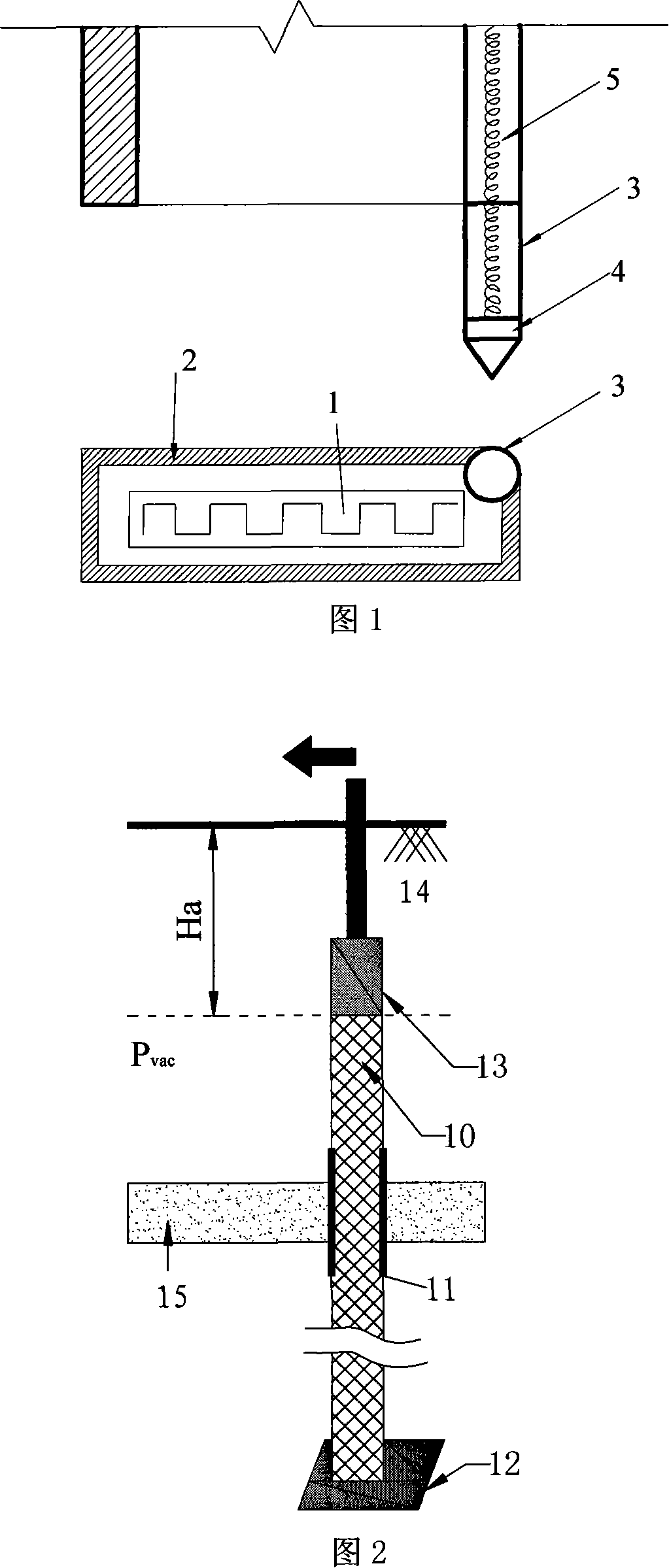

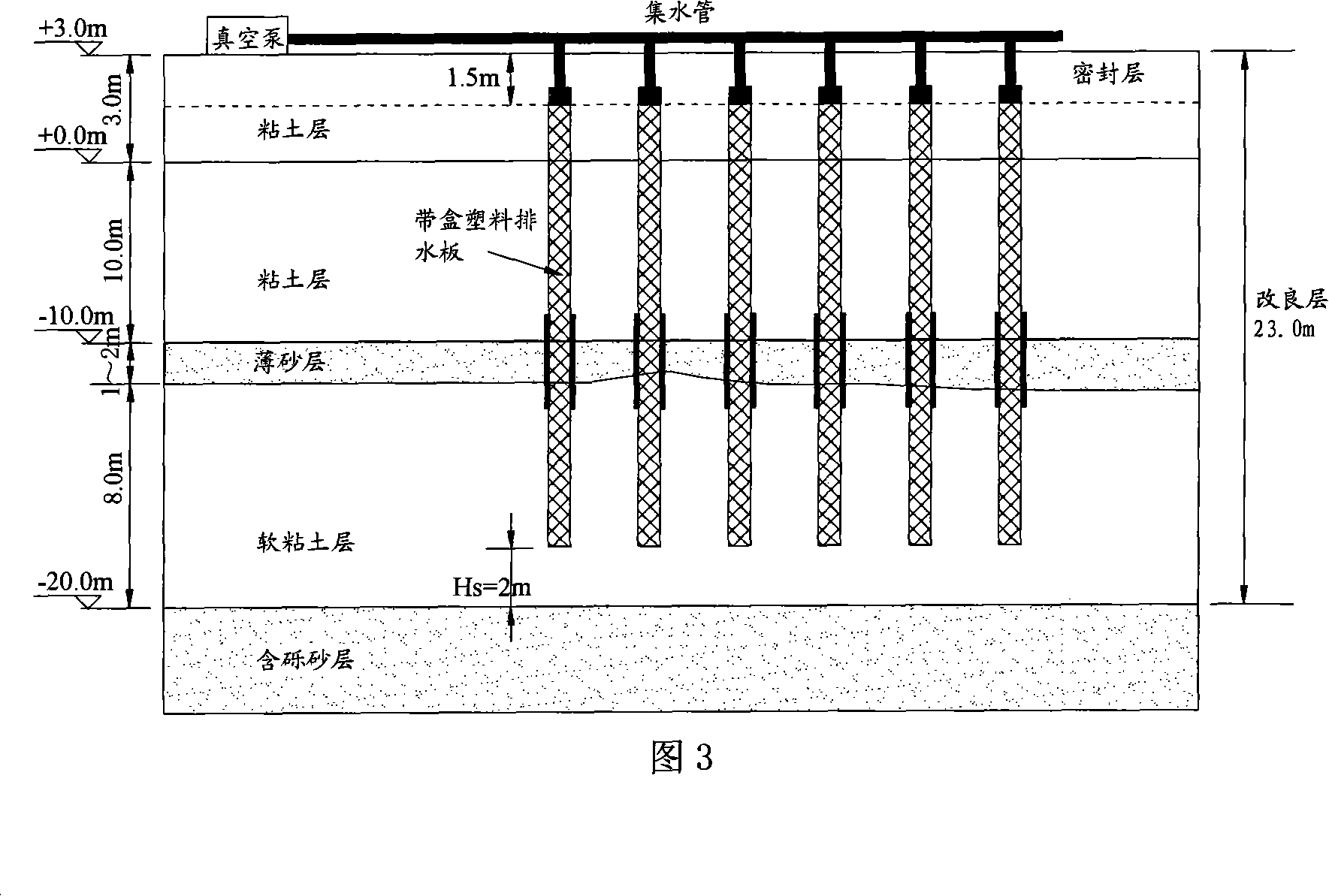

[0023] For a foundation that requires vacuum preloading, it is confirmed that the total thickness of the soft clay layer is 23m, and there is a sand layer below it through the on-site pore pressure static sounding (as shown in Figure 1). Among them, the lower part is the initial accumulation of soft clay layer with a thickness of 8m and the elevation of the top surface of the soil layer is -12.0m; A thin sand layer with a thickness of about 2m. The initial water level is on the surface, that is, the groundwater level is +3.0m. The consolidation coefficient of each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com