Piezoelectric six-dimensional large force sensor

A piezoelectric and sensor technology, applied in the field of piezoelectric sensors, to achieve high precision, improved force compliance and flexibility, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

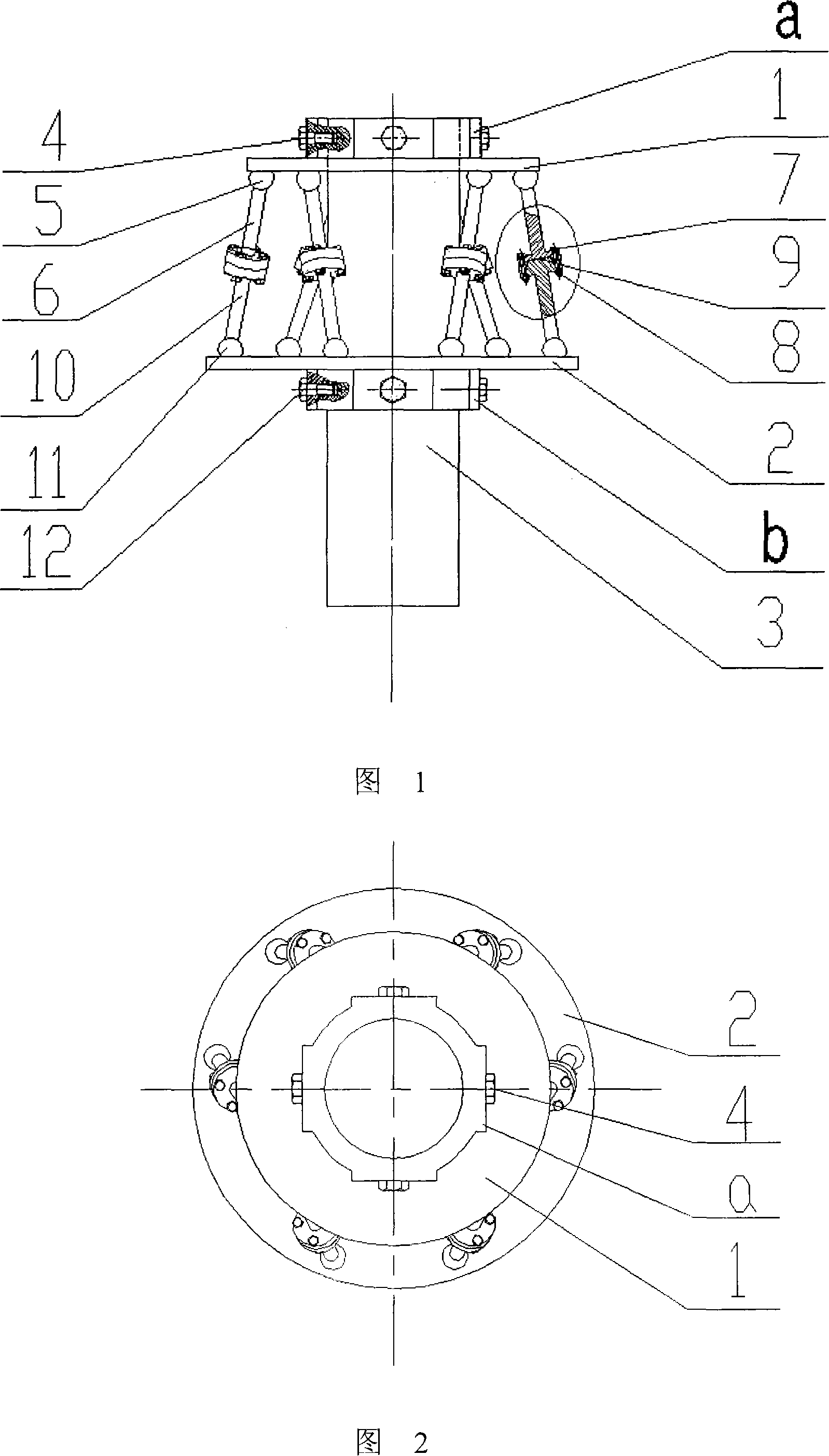

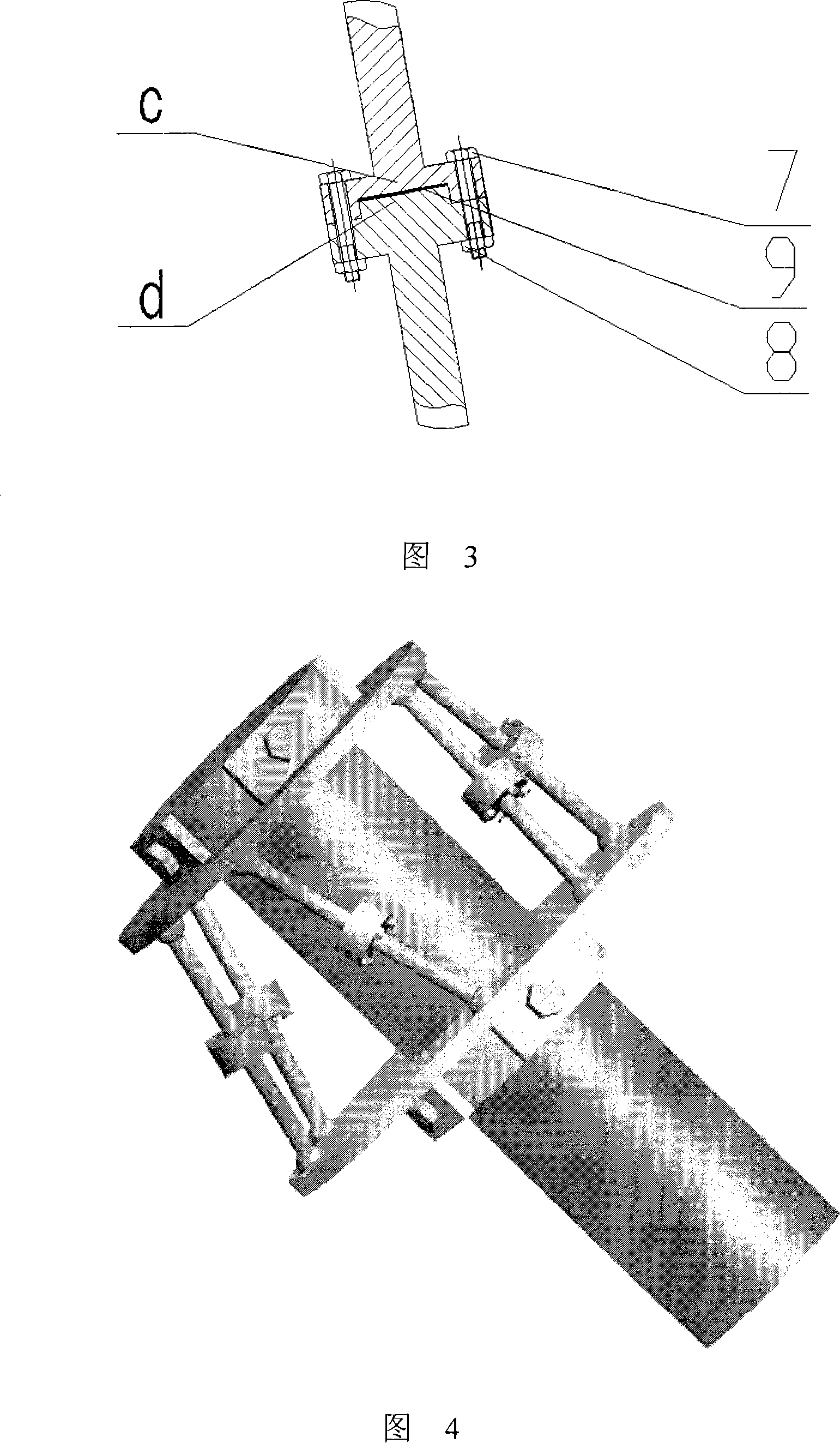

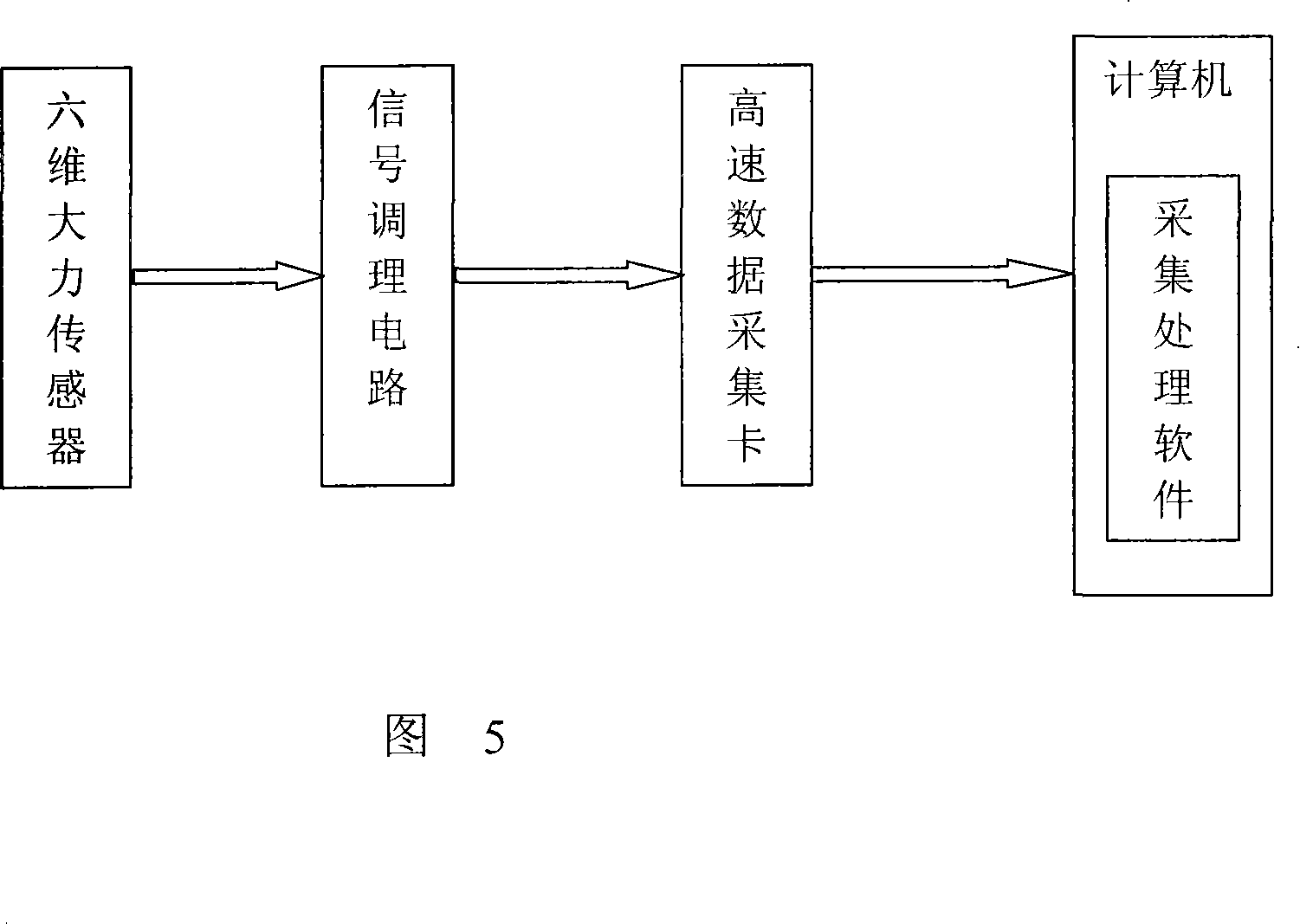

[0011] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The upper and lower platforms are rigidly connected to the manipulator arm 3 by four connecting bolts, and the piezoelectric quartz wafer 9 is embedded in the groove c of the upper rod 6 of the connecting rod, and connected by the upper and lower rods. Bolt 7 and nut 8 install the upper and lower rods of the connecting rod together, and the connecting rod and the upper and lower platforms are connected by spherical hinges. When the manipulator is working, the force of the manipulator is mainly borne by the arm, and a small part of the force is distributed to each connecting rod to realize a strong flow. Because it is connected by a spherical hinge, the connecting rod can be regarded as a two-force rod, which is only affected by the axial force. Pulling pressure, the pulling pressure on the connecting rods is measured by a group of piezoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com