Clock extraction method for patterned medium, clock extraction circuit for patterned medium and patterned medium

A clock extraction and patterning technology, applied in recording/reproducing/deleting methods, patterned record carriers, different record carrier forms, etc., to solve problems such as matching, not realizing the location of clock signals and magnetic dots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

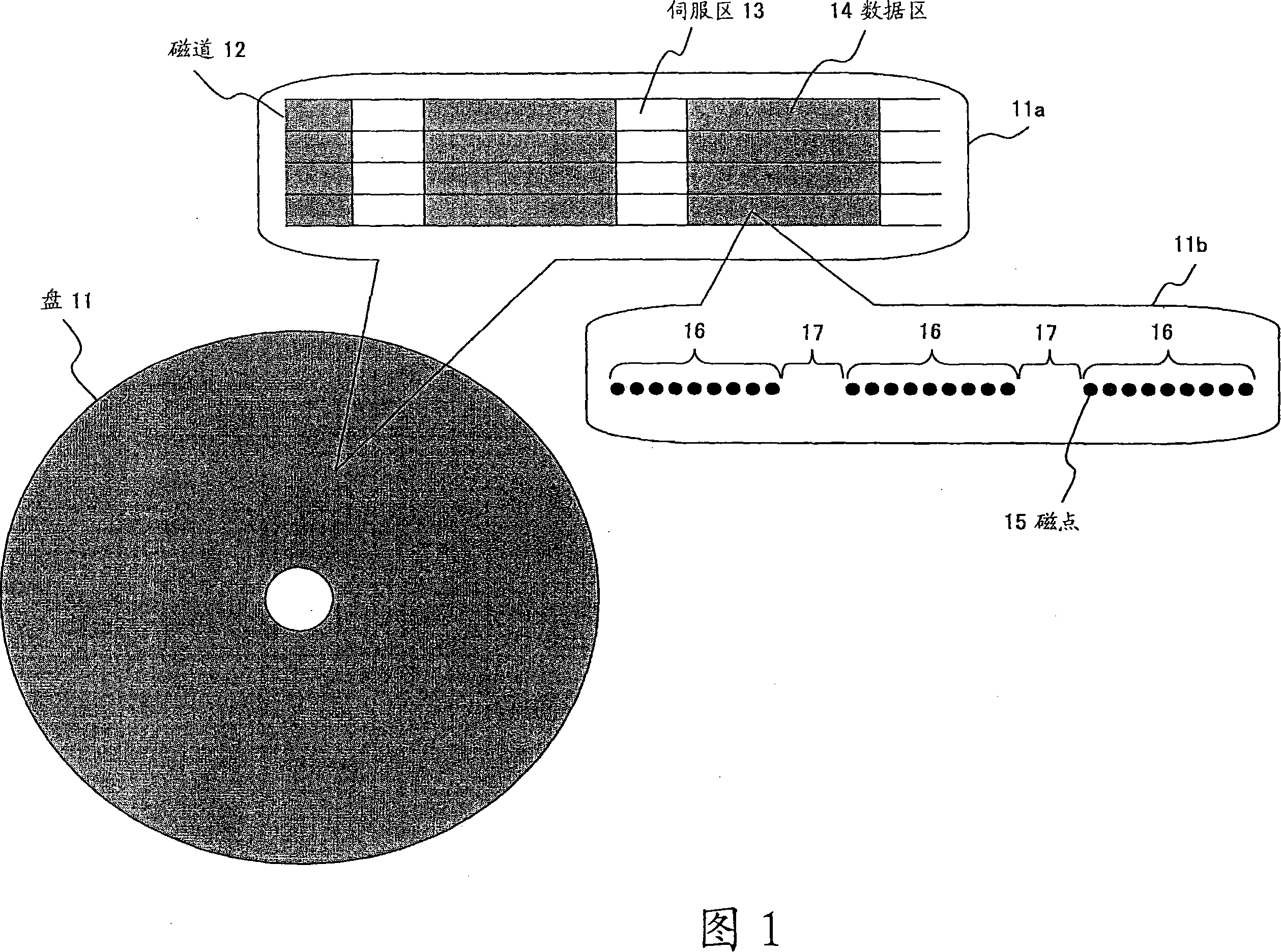

[0041] Preferred embodiments of the present invention are described below by referring to the accompanying drawings. FIG. 1 is a diagram showing the structure of a patterned medium 11 according to a first embodiment.

[0042] Figure 1 shows a patterned medium 11 and its partial enlarged views 11a and 11b. The patterned medium 11 is characterized in that it has: a plurality of tracks 12 in the form of a plurality of concentric circular patterns, each of which is arranged at constant intervals; data for writing and reading locations; and data area 14 .

[0043] The data area 14 is characterized by a magnetic portion 16 in which a plurality of magnetic dots 15 for recording magnetic signals are arranged at certain intervals, and a nonmagnetic portion 17 in which no magnetic dots 15 exist ( That is, no magnetic signal is recorded in this nonmagnetic portion 17). The method of manufacturing the patterned medium 11 can utilize conventional manufacturing methods.

[0044] The pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com