Wastewater analysis sensor cartridge

A sensor box and sensor technology, applied in the analysis of materials, material analysis through electromagnetic means, instruments, etc., can solve the problems of error-prone, difficult sealing, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

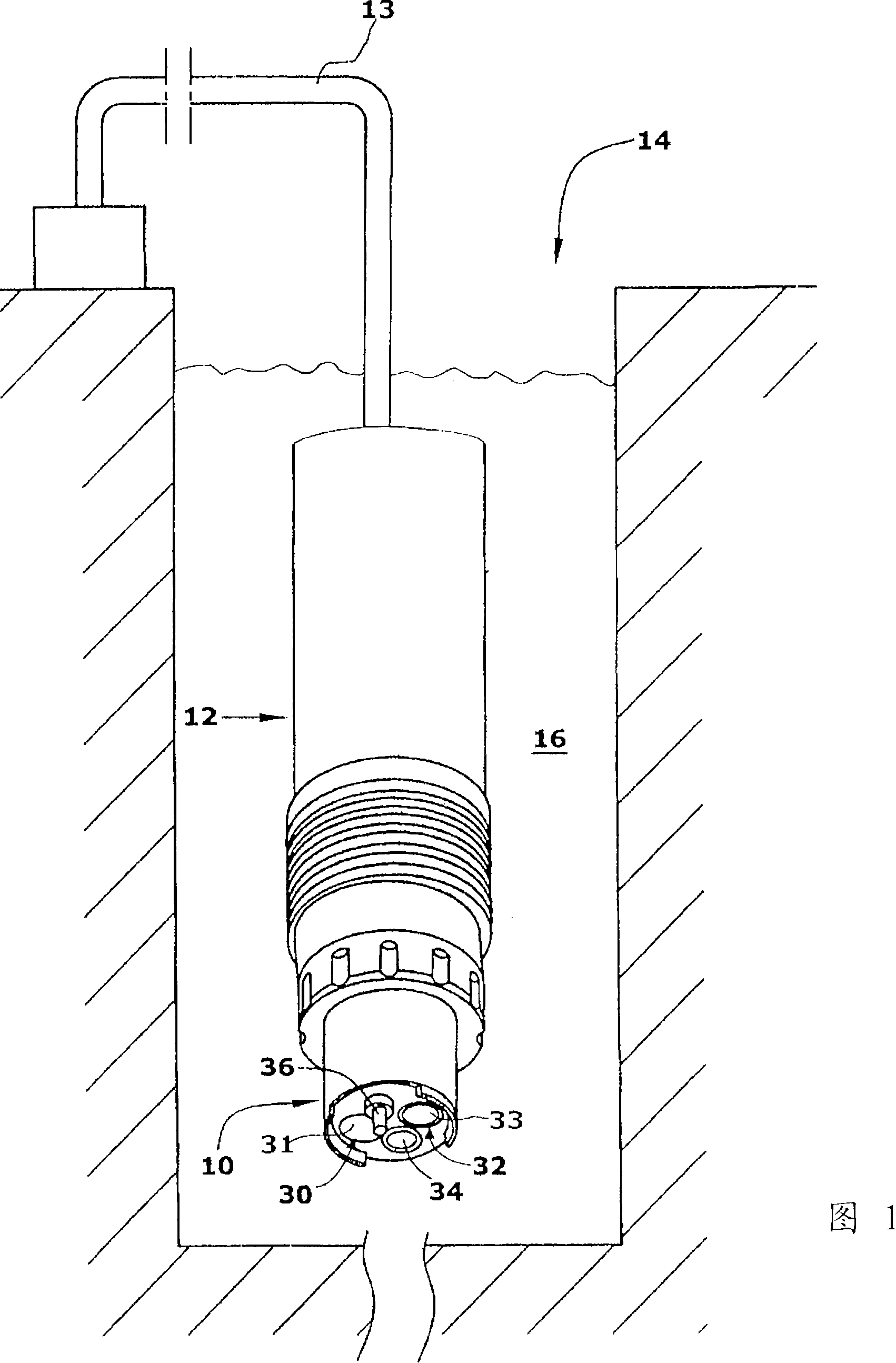

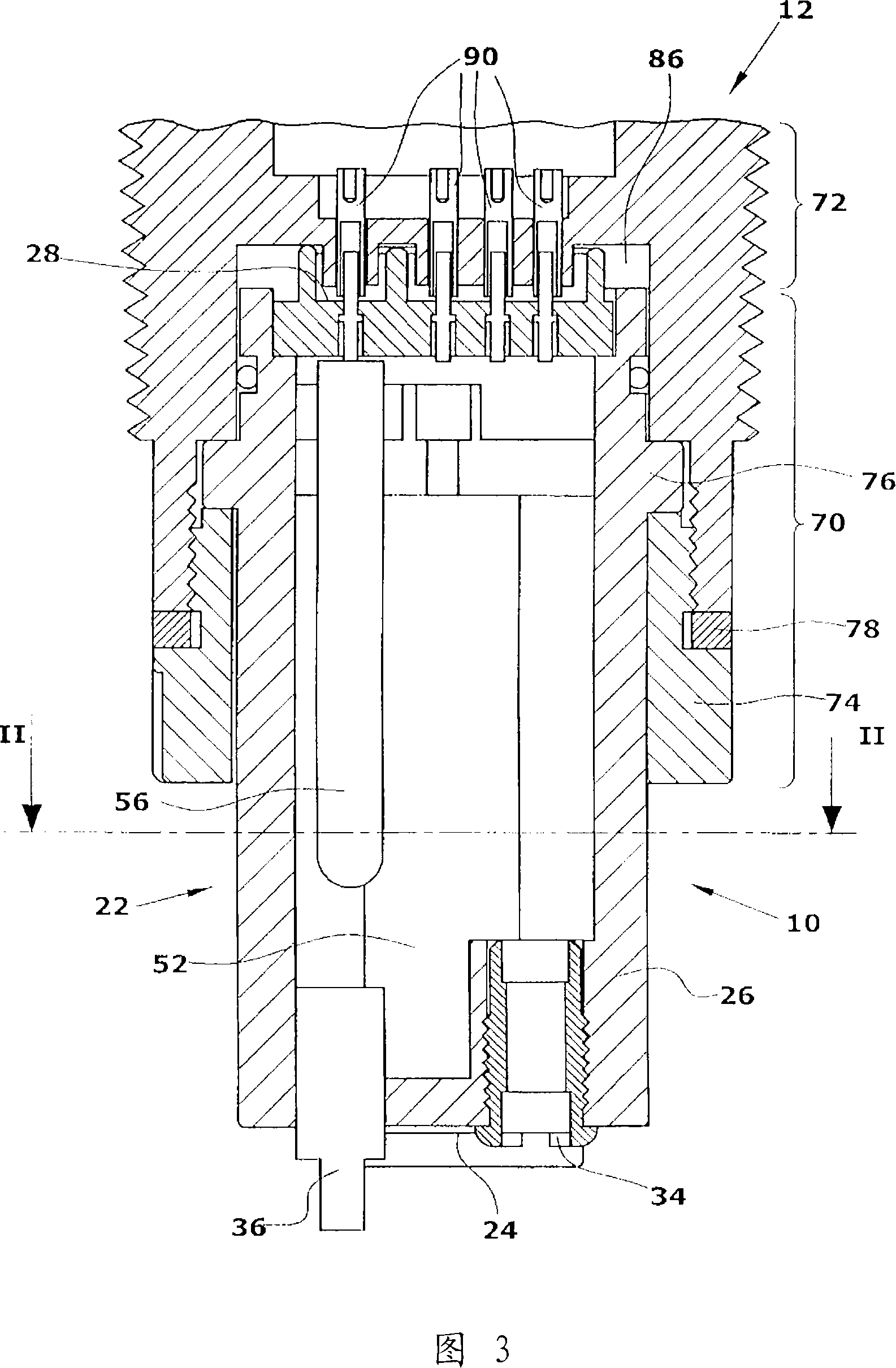

[0030] Figures 1 to 5 show a sensor cartridge 10 for wastewater analysis removably coupled to a ground mounted fixture 12. The fixture 12 together with the sensor box 10 is completely submerged in the wastewater basin 14 of the wastewater treatment plant.

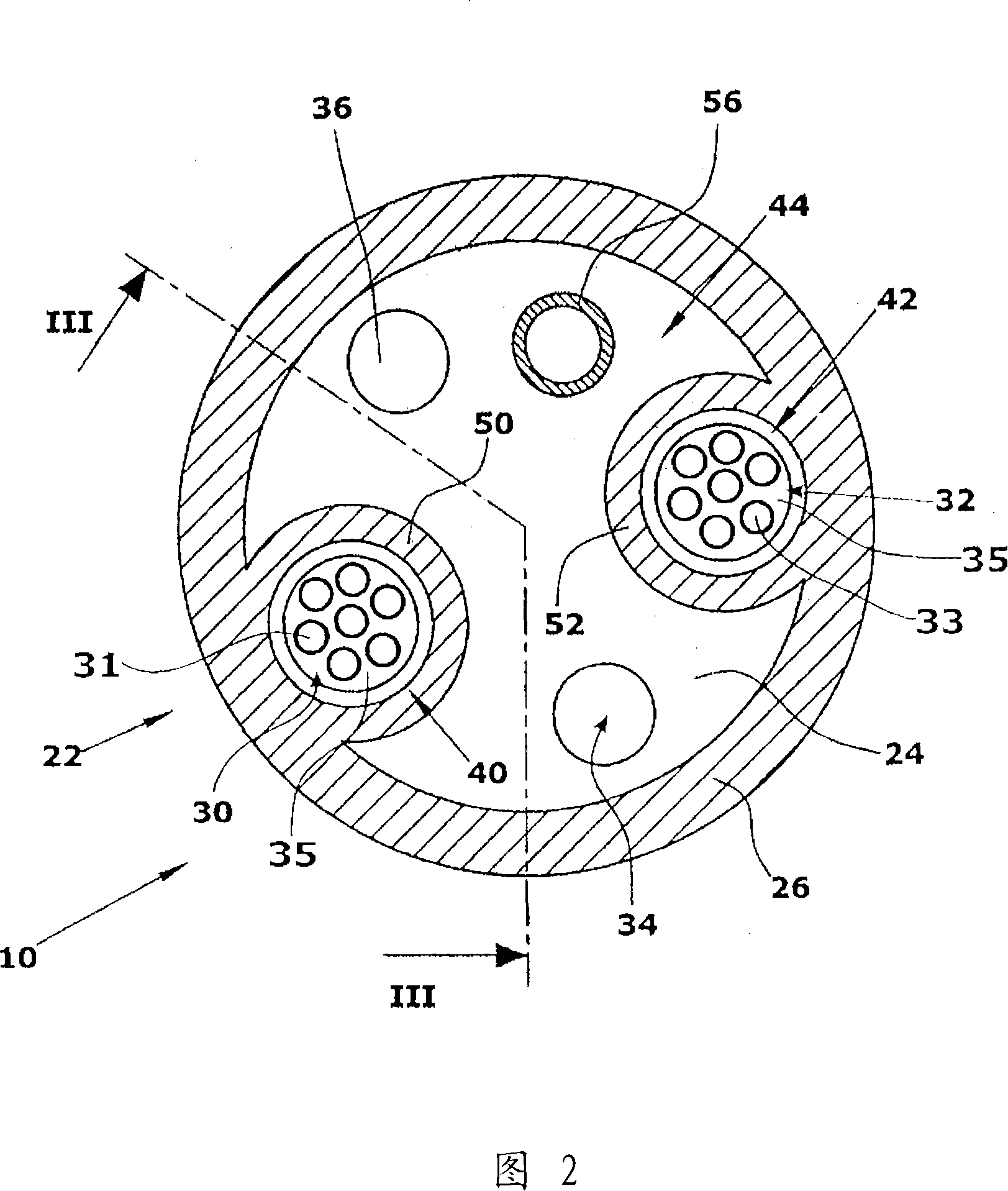

[0031] The sensor cartridge 10 includes a unitary fluid impermeable plastic housing 20 consisting of a housing cup 22 integral with, in turn, a bottom wall 24 , side walls 26 and a cover wall 28 bonded or welded to the housing cup 22 . The housing cup 22 is generally cylindrical. The bottom wall 24 and the side walls 26 form the outer walls of the housing 20 .

[0032] Arranged in the bottom wall 24 of the cup 22 are two electro-chemical sensor elements 30 and 32 , a current key element 34 and a temperature sensor 36 . The rod-shaped reference element 56 protrudes vertically into the housing 20 or cup 22 from above.

[0033] The first electrochemical sensing element 30 functions to measure ammonia electrochemically and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com