Shaft current control brush ring assembly

A technology of brush device and brush ring, which is applied in the direction of electromechanical devices, static electricity, electrical components, etc., can solve the problem of increasing shaft induced current, etc., and achieve the effect of improving grounding performance and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

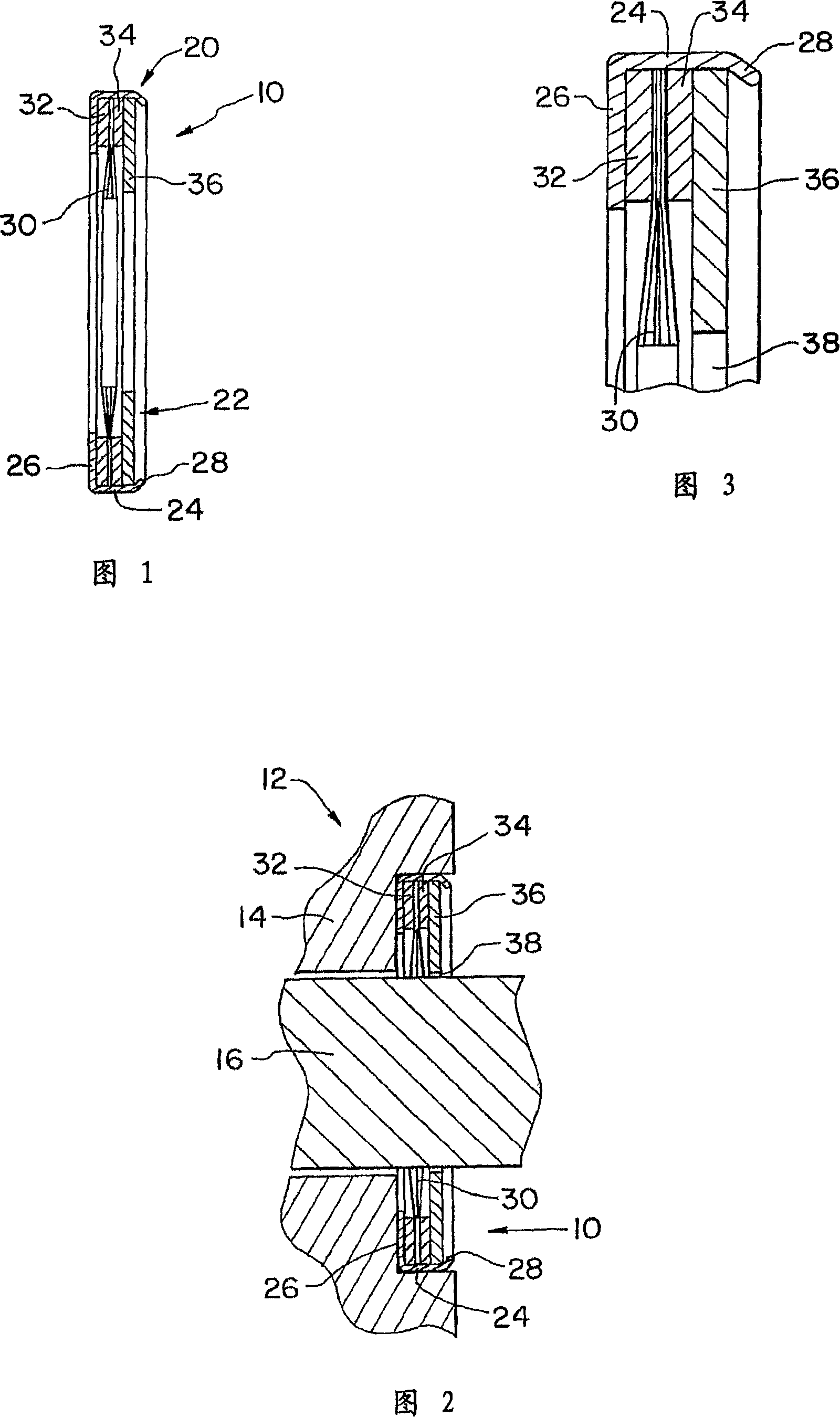

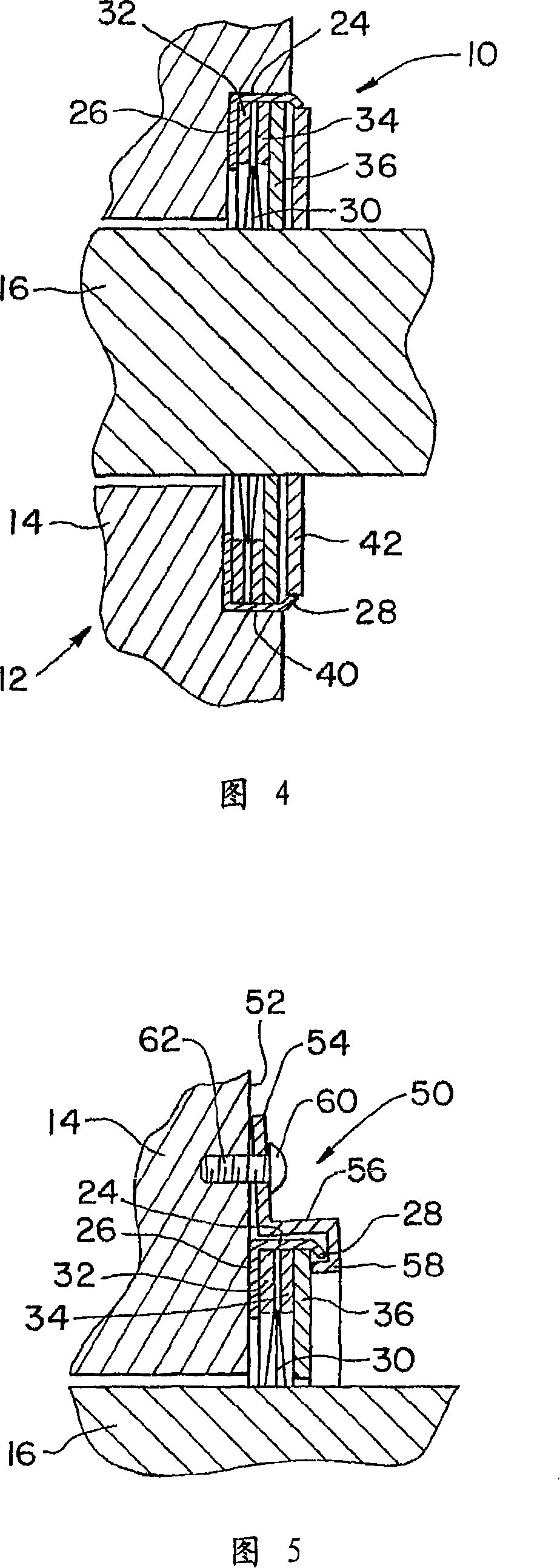

[0025] Referring now more particularly to the drawings and to FIG. 1 in particular, reference numeral 10 indicates a shaft current control brush ring arrangement according to the invention. The brush ring arrangement 10 is mounted on the motor 12 ( FIG. 2 ) and in particular on the faceplate 14 of the motor 12 for dissipating electrical charge that may accumulate on the shaft 16 of the motor 12 . It should be understood that the brush ring assembly 10 may be provided in a variety of different sizes for use in different types of electric machines and on shafts 16 of different diameters.

[0026] The brush ring assembly 10 is generally annular, surrounding an axis 16 . The brush ring assembly 10 is fixed to the panel 14 and is operably mounted between the spindle 16 and the panel 14 . The brush ring arrangement 10 operates continuously to remove charge that builds up on the motor shaft 16 during operation of the motor 12 by transferring the charge from the main shaft 16 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com