Explosion-proof easy heat radiation type three-phase asynchronous motor

A three-phase asynchronous, heat-dissipating technology, used in asynchronous induction motors, electric components, electrical components, etc., can solve the problems of motor heat not being discharged in time, shortening the service life of the motor, affecting the explosion-proof performance of the motor, etc., to protect the safe operation. , The effect of reducing eddy current loss and reducing magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following descriptions are only preferred embodiments of the present invention, and do not limit the protection scope of the present invention. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

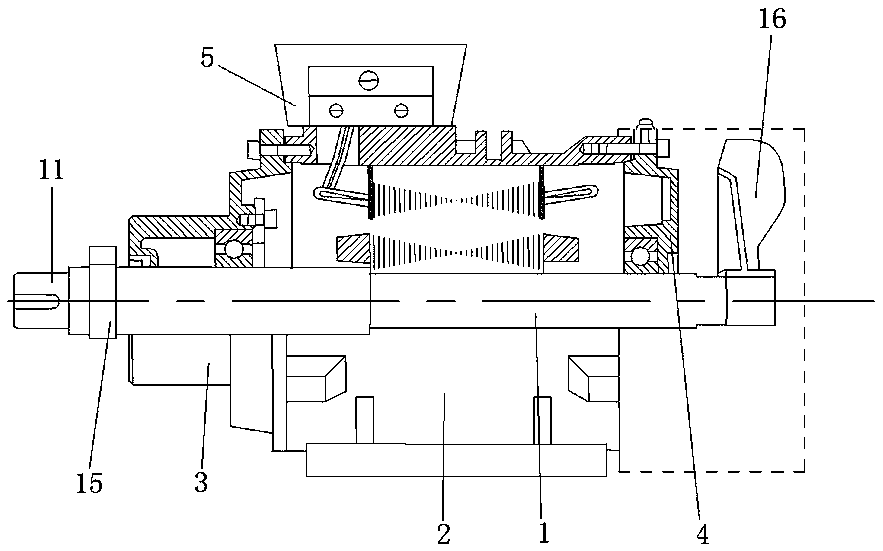

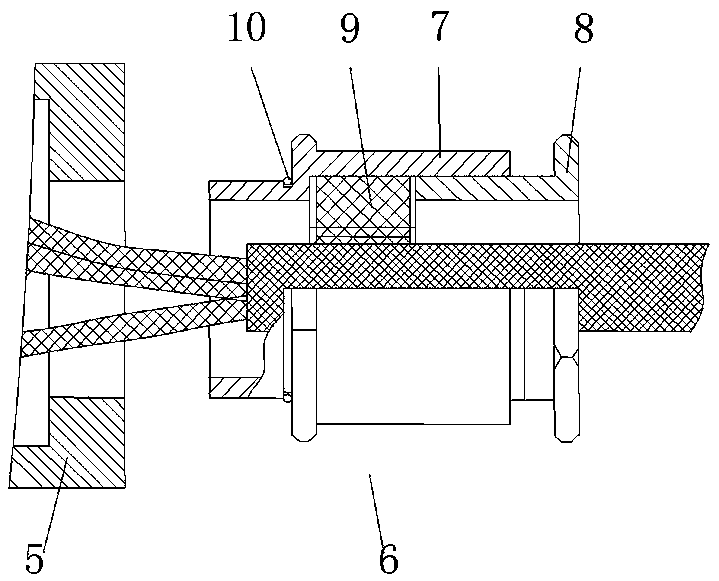

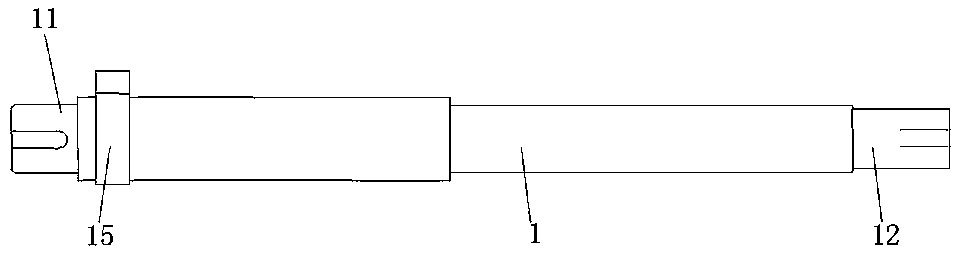

[0018] Examples, see Figure 1 to Figure 5 Shown: an explosion-proof and easy-to-heat-radiation three-phase asynchronous motor, including a stator, a rotor, a rotating shaft 1, a motor housing 2, and a front end cover 3 and a rear end cover 4 installed at the front and rear ends of the motor housing 2. The rotating shaft 1 is horizontally installed in the motor casing 2 and the rotating shaft 1 protrudes outside the front end cover 3 and the rear end cover 4, and a junction box 5 is installed outside the motor casing 2, and the stator and rotor The copper wires are all wrapped with high-strength polyester paint, and the junction box 5 is provided with three flameproof joints 6 for cable access. Tighten the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com