Rator unit, method for manufacturing the rator unit, motor and pump having the same

A technology of a rotor unit and a manufacturing method, applied in the fields of motors and pumps, can solve problems such as failure of electronic parts, poor electrical connection, warpage of a circuit substrate 3, etc., and achieve the effects of improving close contact, preventing warping, and narrowing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] [Overall structure of the rotor unit]

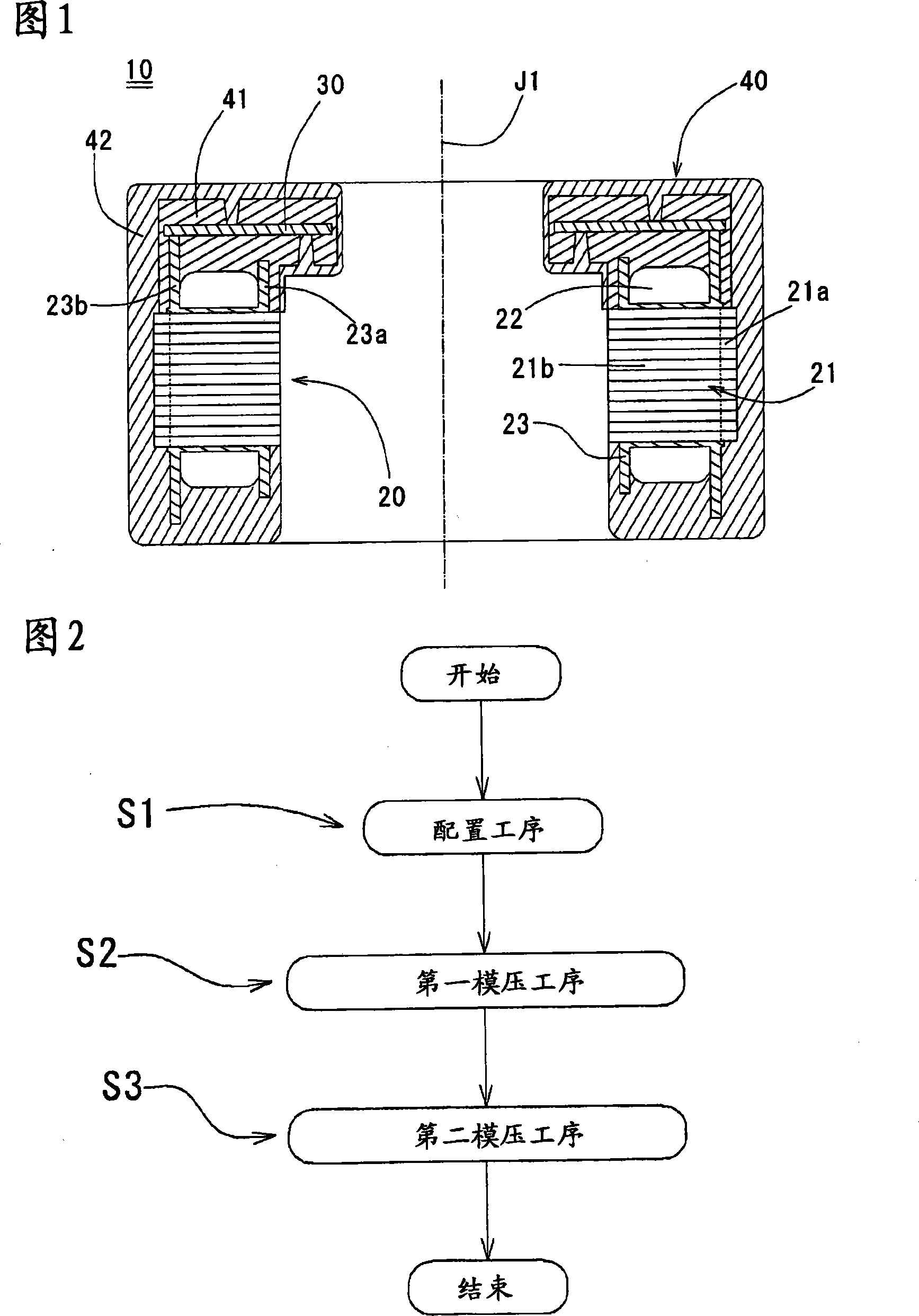

[0074] One mode of an embodiment of the overall structure of the rotor unit of the present invention will be described with reference to FIG. 1 . FIG. 1 is a schematic cross-sectional view cut along the axial direction showing one mode of an embodiment of a rotor unit. Here, the axial direction in FIG. 1 is the direction along the axis J1. In addition, the expressions of the upper side and the lower side in the following specification are expressions in the drawings, and do not specify the direction of gravity.

[0075] Referring to FIG. 1 , the rotor unit 10 has a rotor 20 , a circuit board 30 disposed on the axially lower side of the rotor 20 , and a molded portion 40 that molds the rotor 20 and the circuit board 30 .

[0076] The rotor 20 has a stator core 21 formed by laminating thin magnetic steel plates in the axial direction of a predetermined axis J1, a coil 22 formed by laminating electric wires in multiple layers and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com