Method and apparatus for liquefying a natural gas stream

A technology of natural gas and gas flow, applied in lighting and heating equipment, liquefaction, refrigeration and liquefaction, etc., can solve the problems of insufficient and complicated recovery of compounds, and achieve the effect of increasing recovery, maintaining the same refrigeration power and increasing production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] For purposes of illustration, a single reference number will be assigned to a pipeline and the streams carried in that pipeline. Like reference numbers refer to like components.

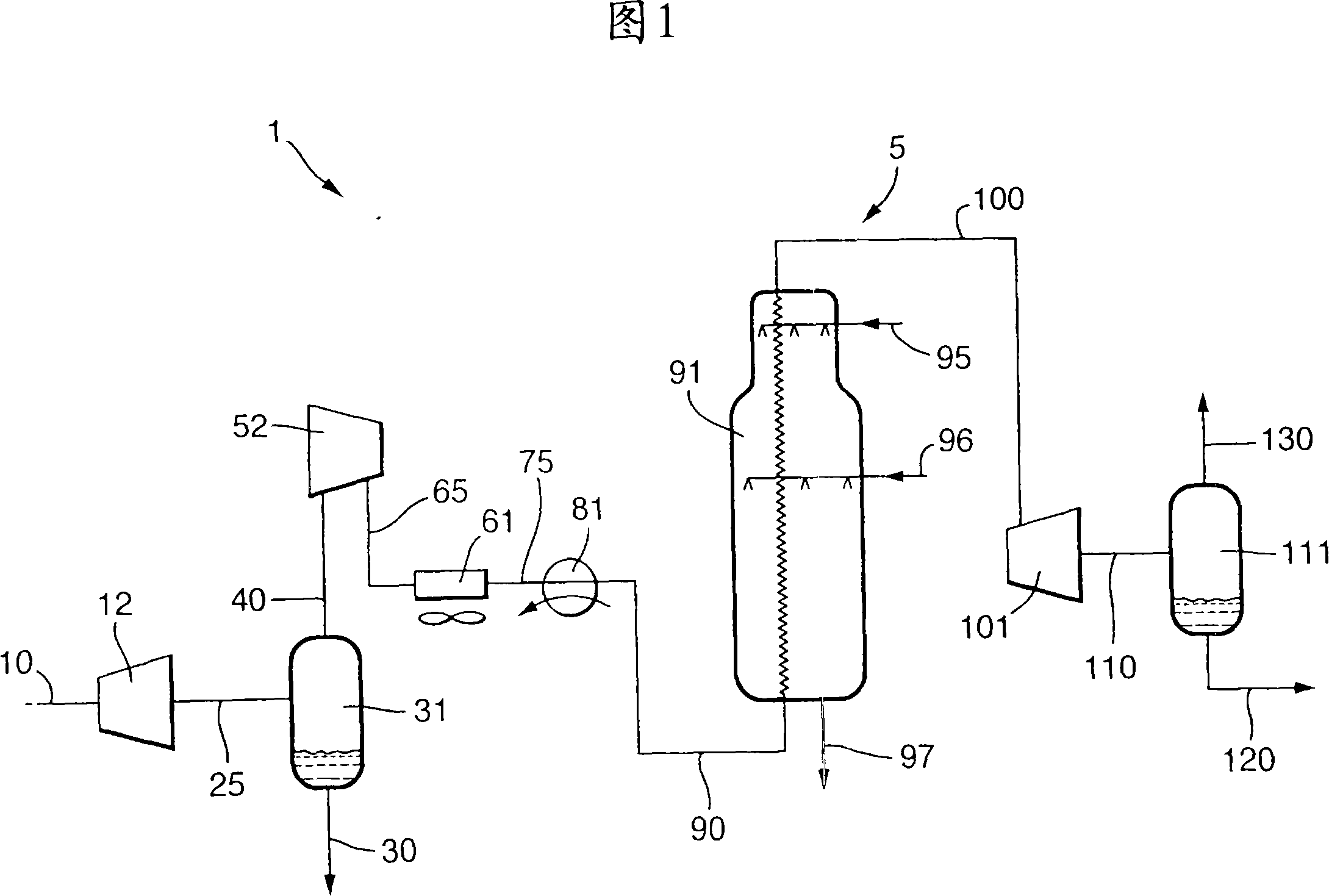

[0047] Figure 1 schematically shows a baseload liquefied natural gas (LNG) export process and an apparatus (indicated generally with reference numeral 1) for carrying out the export process. After being expanded in the expander 12, the feed stream 10 containing natural gas is supplied to the gas / liquid separator 31 at a specific inlet pressure and inlet temperature. Typically, the pressure of stream 10 will be between 30 bar and 80 bar (preferably >60 bar and <70 bar), and the temperature will be close to ambient, usually between 5°C and 50°C.

[0048] If desired, feed stream 10 may be pretreated prior to its introduction into expander 12 . For example, feed stream 10 may be pre-cooled by coolant in one heat exchanger (not shown), or in a series of heat exchangers, for example comprising two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com