Novel thermal recovery well head device

A wellhead device, thermal recovery technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The invention is given by the following examples.

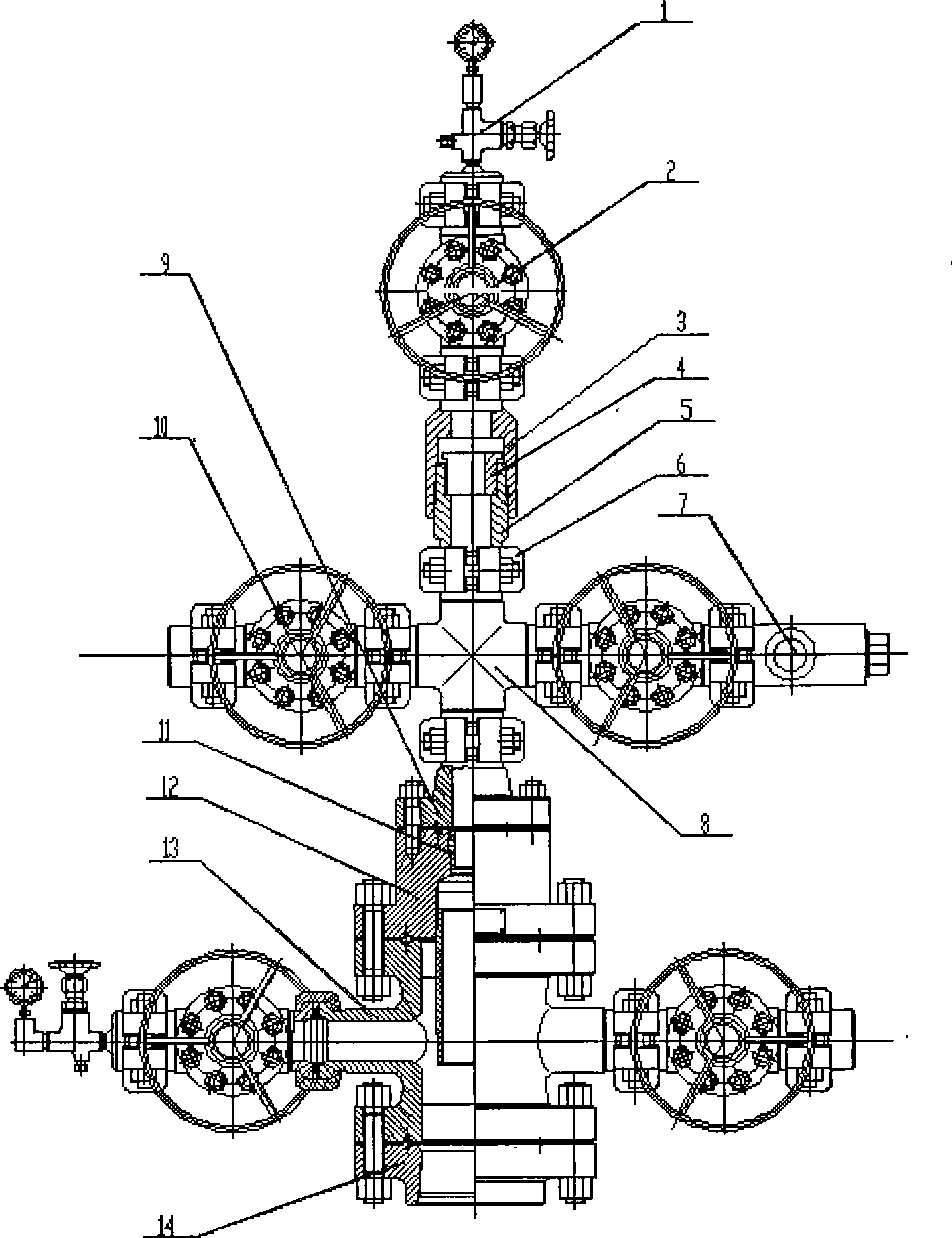

[0010] In the accompanying drawings, a new type of thermal recovery wellhead device consists of a needle-shaped air release valve 1, a closed gate valve 2, an upper threaded clamp reducing diameter 3, a card seat 4, a lower threaded clamp reducing diameter 5, a clamp 6, a throttling 7, small cross 8, flange clamp reducer 9, wing valve 10, protective wire 11, upper flange 12, large cross 13, casing flange 14; needle-shaped air release valve 1 and closed gate valve 2. Lower threaded clamp reducer 5 and small cross 8, small cross 8 and flange clamp reducer 9, restrictor 7 and wing valve 10 are all connected by clamp 6, and clamp 4 sits on the lower thread clamp On the upper step of hoop reducer 5, the upper threaded clamp reducer 3 is threadedly connected with the lower threaded clamp reducer 5, and the protective wire 11 is tightened to protect the thread in the upper flange 12. Firstly, the casing flange 14 and the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com