Turbine rotor and steam turbine

A turbine rotor and steam turbine technology, applied in the field of steam turbines, can solve problems such as large thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

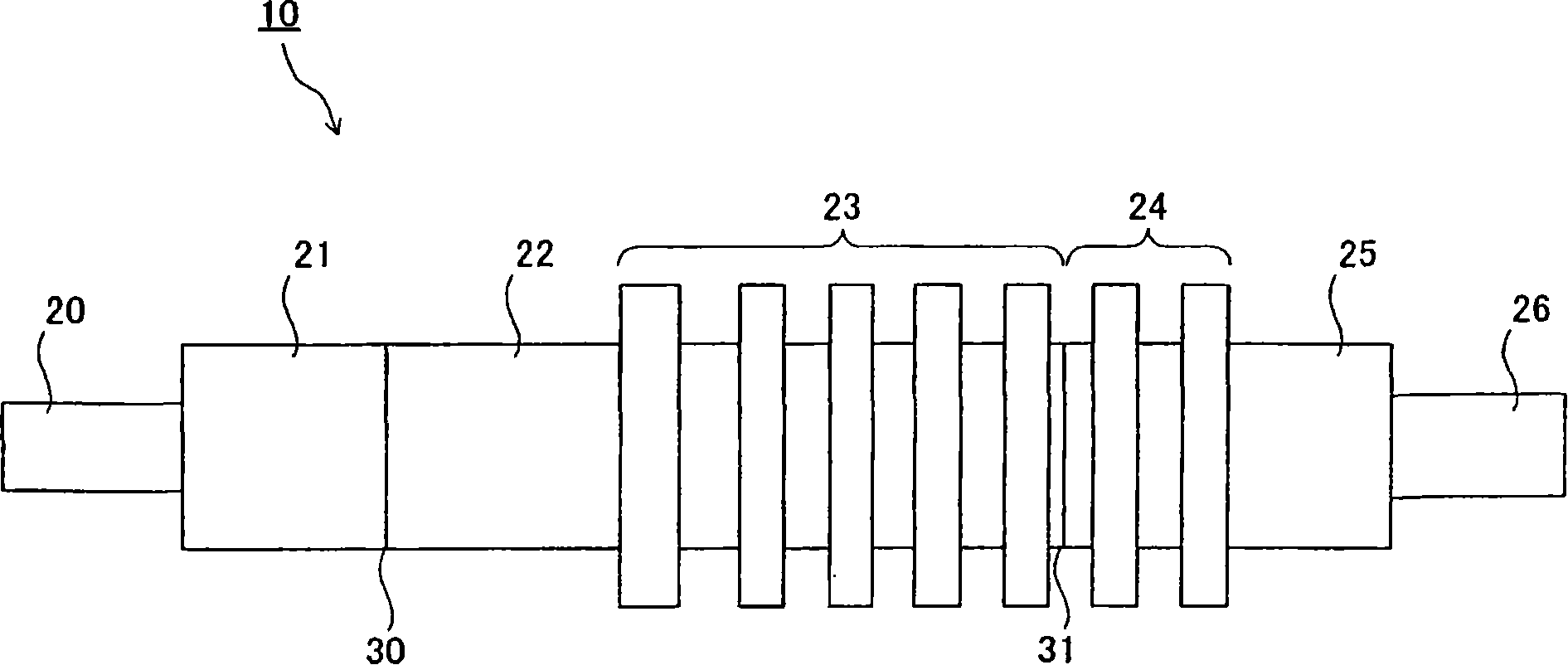

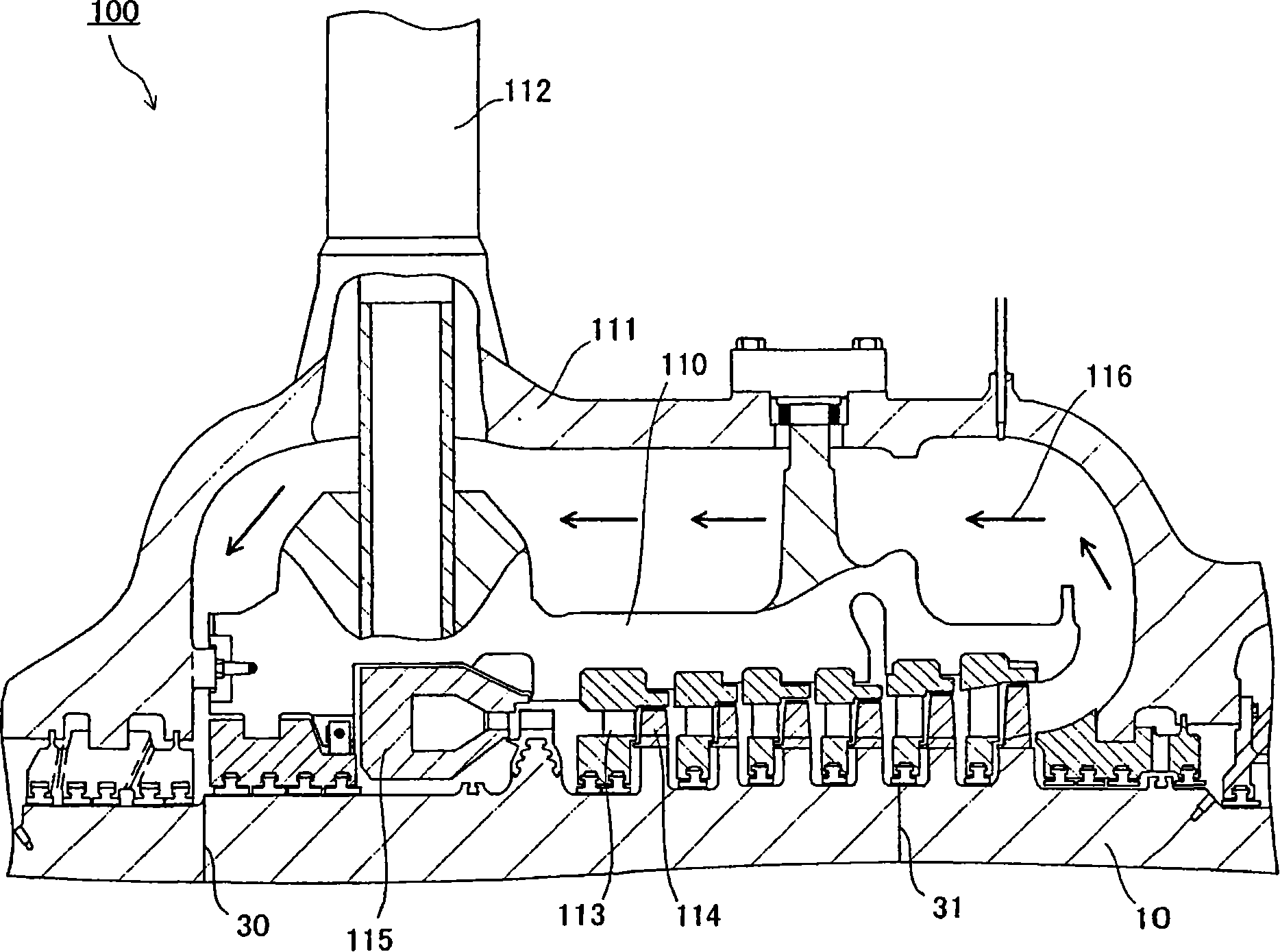

[0032] figure 1 It is a plan view schematically showing the configuration of the turbine rotor 10 according to the first embodiment of the present invention.

[0033] Such as figure 1 As shown, the turbine rotor 10 includes: a front shaft 20, a front low temperature sealing part 21, a front high temperature sealing part 22, a front high temperature moving blade part 23, a rear low temperature moving blade part 24, a rear low temperature sealing part 25, and rear axle 26 .

[0034] The front shaft 20 and the front cryogenic seal 21 are integrally formed. In addition, the front high-temperature sealing part 22 and the front high-temperature rotor blade part 23 in which the rotor blades are fitted are integrally formed. Furthermore, the rear shaft 26 , the rear low-temperature seal portion 25 , and the rear low-temperature rotor blade portion 24 in which the rotor blades are embedded are also integrally formed. In addition, the front low-temperature sealing part 21 is connect...

no. 2 Embodiment approach

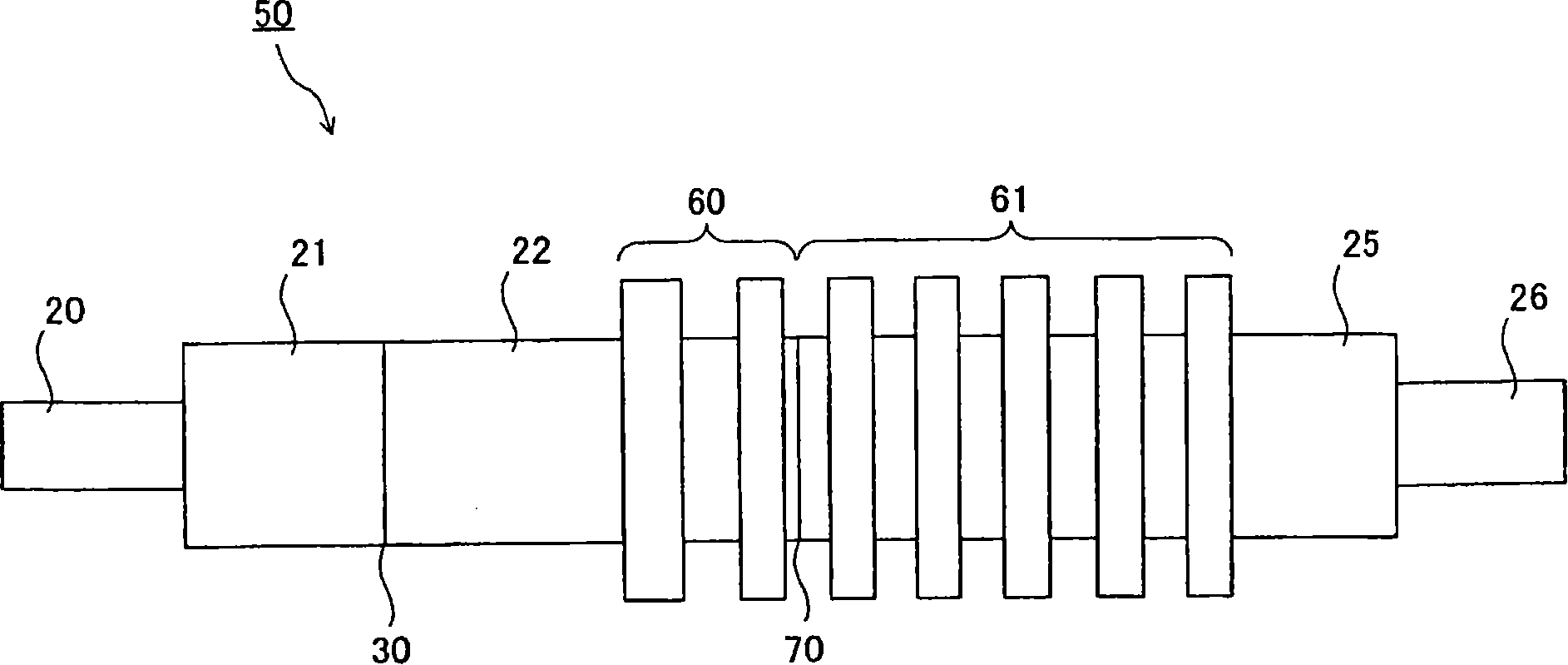

[0070] image 3 It is a plan view schematically showing the configuration of a turbine rotor 50 according to a second embodiment of the present invention. In addition, the same code|symbol is attached|subjected to the same component as the structure of the turbine rotor 10 of 1st Embodiment, and repeated description is abbreviate|omitted or simplified here.

[0071] Here, the configuration of the turbine rotor 50 of the second embodiment is the same as that of the first embodiment except that the configurations of the front high-temperature rotor blade portion 23 and the rear low-temperature rotor blade portion 24 of the turbine rotor 10 of the first embodiment are changed to provide a cooling mechanism. The configuration of the turbine rotor 10 of the first embodiment is the same. Such as image 3 As shown, the turbine rotor 50 includes: a front shaft 20, a front low temperature sealing part 21, a front high temperature sealing part 22, a front high temperature moving blade...

Embodiment 1 and comparative example 1

[0084]Here, the Ni-based alloy and CrMoV steel used in the turbine rotor of the present invention are used, and the Ni-based alloy and CrMoV steel are deposited to form a turbine rotor, which is assumed to be Test Sample 1 (Example 1). The Ni-based alloy and 12Cr steel used in the dissimilar welded turbine rotor were deposited on the Ni-based alloy and 12Cr steel to form the turbine rotor, which was assumed to be the test sample 2 (comparative example 1), and calculated in the respective Thermal stress at the junction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com