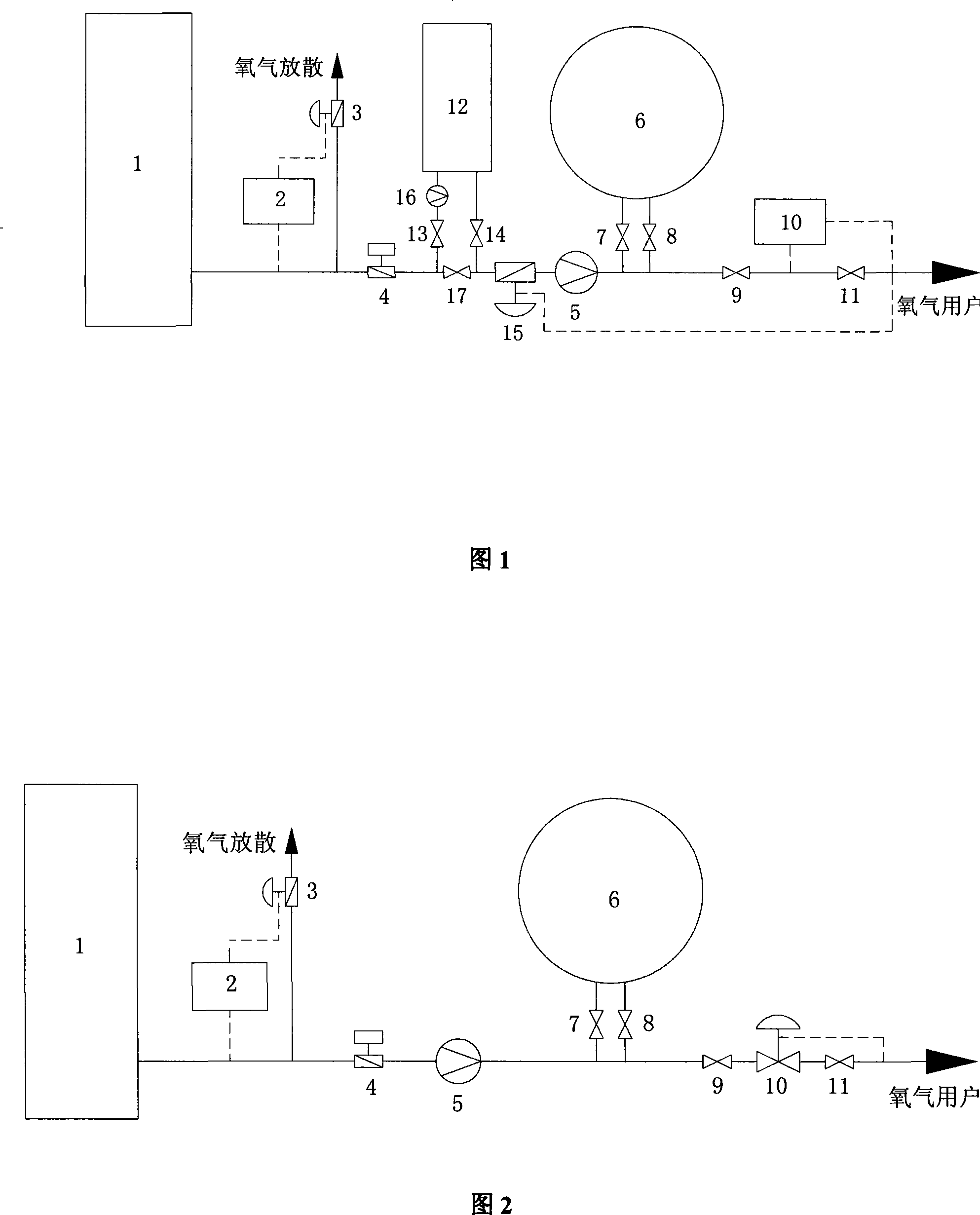

Space-insolated oxygen gas conveying system and method for pressure releasing and energy-saving by coal wind chest technology

A technology of gas cabinets and oxygen, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., and can solve the problems that cannot meet the peak regulation requirements of large-scale air separation systems, and the volume of gas storage bags and gas cabinets is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0030] The total oxygen output of the air separation unit of a large iron and steel company in my country is 230000Nm 3 / h, according to the statistics of the pressure data of 28 days of normal production, the maximum pressure is 2.56MPa, the minimum pressure is 1.73MPa, and the average pressure is 2.16MPa. According to pressure fluctuations, pipeline conditions, spherical tank volume, etc., it is calculated that it will take 70,000 m 3 The gas cabinet is used to adjust the fluctuation of the amount of oxygen used by the user, so as to stabilize the pressure of the pipe network and reduce the release of oxygen. Considering the problem of the minimum operating volume of the gas cabinet and special circumstances (such as the increase of oxygen users, etc.), the volume utilization coefficient of the dry cabinet is 0.9, the gas volume correction coefficient is 1.263, and the oxygen system is selected as 100,000 m 3 The gas cabinet is used as a gas storage device.

[0031] After ...

Embodiment example 2

[0033] The total oxygen output of the air separation unit of a medium-sized iron and steel company in my country is 63000Nm 3 / h, according to the statistics of the pressure data of 15 days of normal production, the maximum pressure is 3.06MPa, the minimum pressure is 1.75MPa, and the average pressure is 2.57MPa. According to pressure fluctuations, pipeline conditions, spherical tank volume, etc., it is calculated that 30,000 m 3 The gas cabinet is used to adjust the fluctuation of the amount of oxygen used by the user, so as to stabilize the pressure of the pipe network and reduce the release of oxygen. Considering the problem of the minimum operating volume of the gas cabinet and special circumstances (such as the increase of oxygen users, etc.), the volume utilization coefficient of the dry cabinet is 0.9, the gas volume correction coefficient is 1.263, and the oxygen system is selected as 50,000 m 3 The gas cabinet is used as a gas storage device.

[0034] After adding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com