A method for improving the pressure fluctuation control process of oxygen pipeline network

An oxygen tube and pressure technology, which is applied in the field of improving the pressure fluctuation control process of the oxygen pipe network, can solve the pressure fluctuation deviation of the oxygen spherical tank, cannot grasp the production status of the oxygen consumption equipment in time, and affects the accuracy of the oxygen production prediction of the oxygen production equipment, etc. problem, to achieve the effect of improving the prediction accuracy, optimizing the pressure fluctuation control process of the oxygen pipeline network, and improving the pressure fluctuation control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

[0054] 1. Oxygen consumption flow dynamic prediction scheme

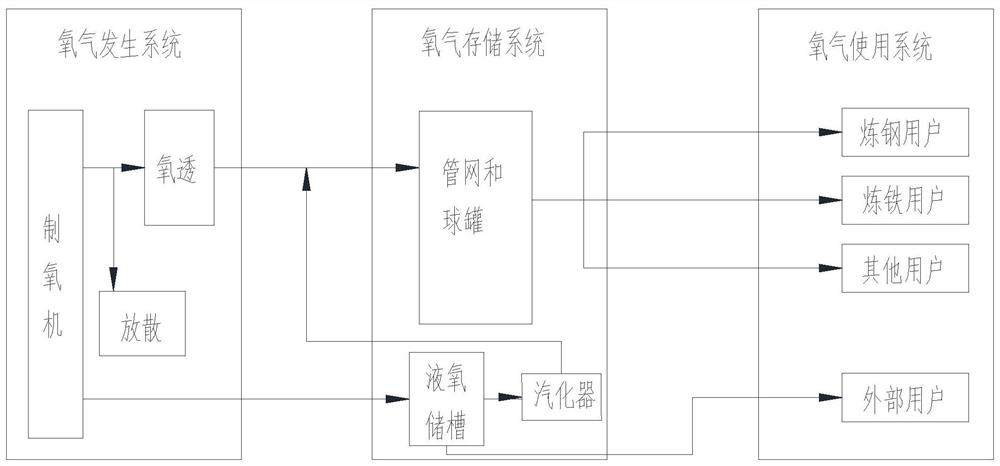

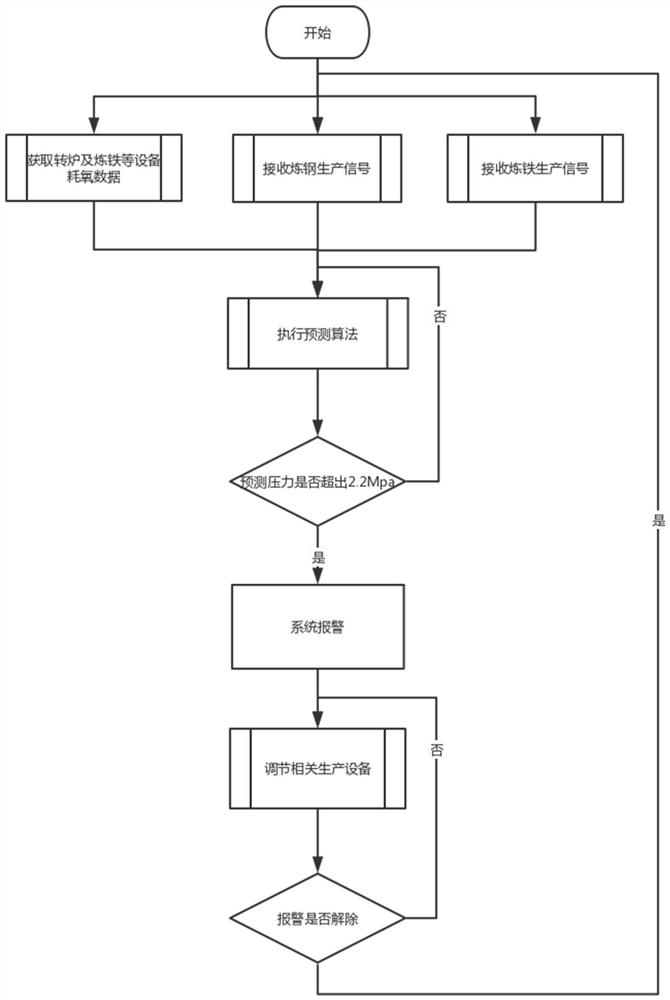

[0055] Schematic diagram of oxygen supply and demand balance in a steel plant figure 1 As shown, the flow chart of the pressure fluctuation control process of the oxygen pipe network is as follows figure 2 shown. First obtain the oxygen consumption data of the converter and ironmaking equipment, receive the steelmaking production signal, and receive the ironmaking production signal. In practice, the oxygen consumption flow of the equipment will not be a stable value, but will fluctuate up and down within a certain range. In order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com