Pipe network system and method for increasing oxygen yield by using surplus compressed air

A technology of compressed air pipes and compressed air, applied in the field of oxygen generators, can solve the problems of energy waste, increase the cost of supply guarantee, and decrease in oxygen production, and achieve the effects of ensuring oxygen production, increasing oxygen production, and reducing the emission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on the specific embodiments and in conjunction with the accompanying drawings.

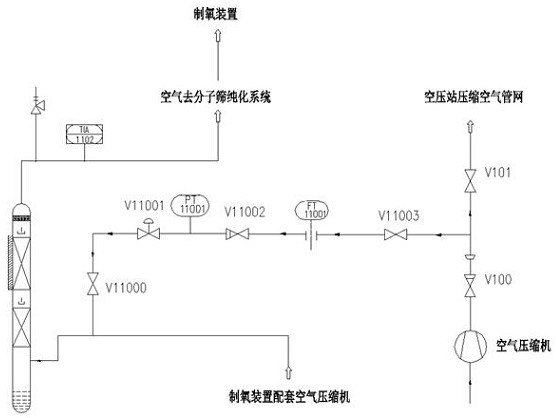

[0029] This embodiment provides a pipe network system that utilizes surplus compressed air to increase oxygen production, including the compressed air pipe network of the air compressor station, the compressed air pipe network is connected to the constant pressure delivery pipeline, The excess compressed air from the road compressed air pipeline network is sent to the oxygen generator, and the oxygen generator converts the compressed air into oxygen, nitrogen, and argon products.

[0030] Specifically, the compressed air pipeline network communicates with the inlet end of the constant pressure delivery pipeline through the third cut-off valve V101. The constant pressure pipeline adopts PN1.0, DN200 seamless carbon steel pipeline. The first sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com