Plate-fin heat exchanger

A technology of plate-fin heat exchangers and plate bundles, applied in the field of plate-fin heat exchangers, can solve the problems of limited materials and narrow application fields of plate-fin heat exchangers, and reduce the workload and difficulty of work , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

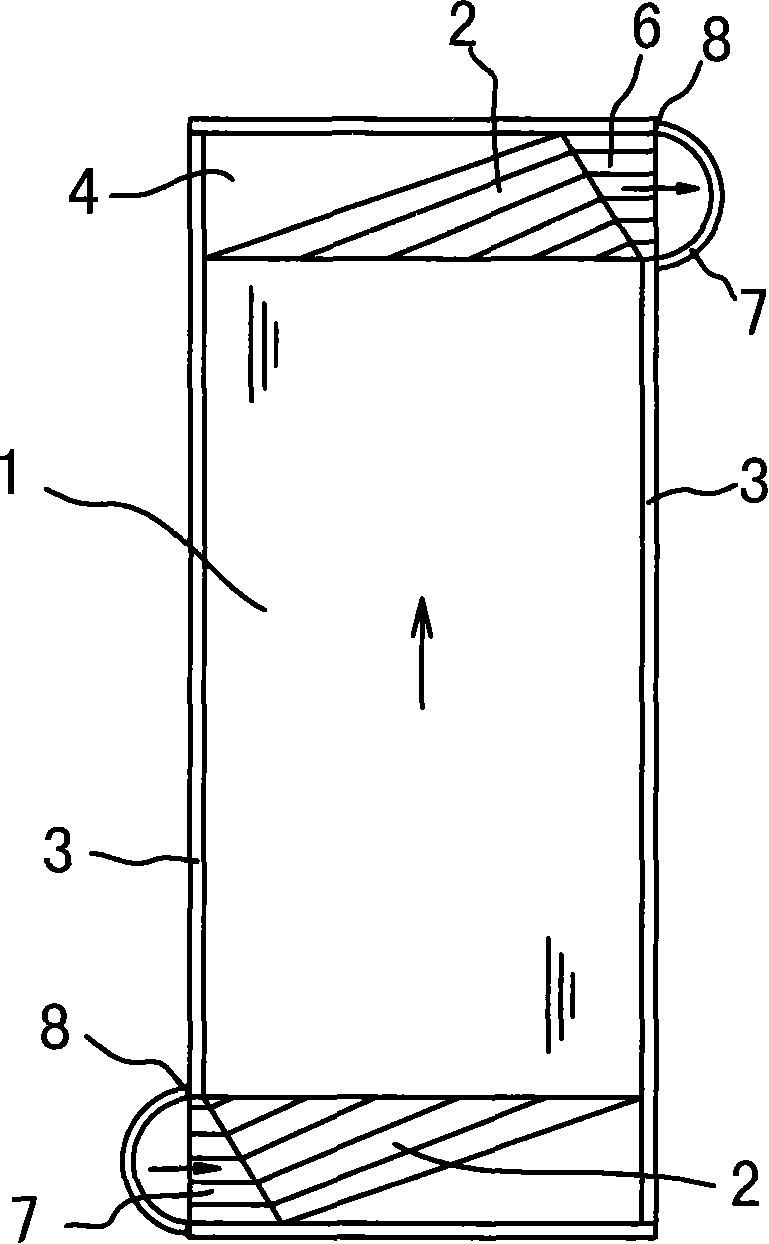

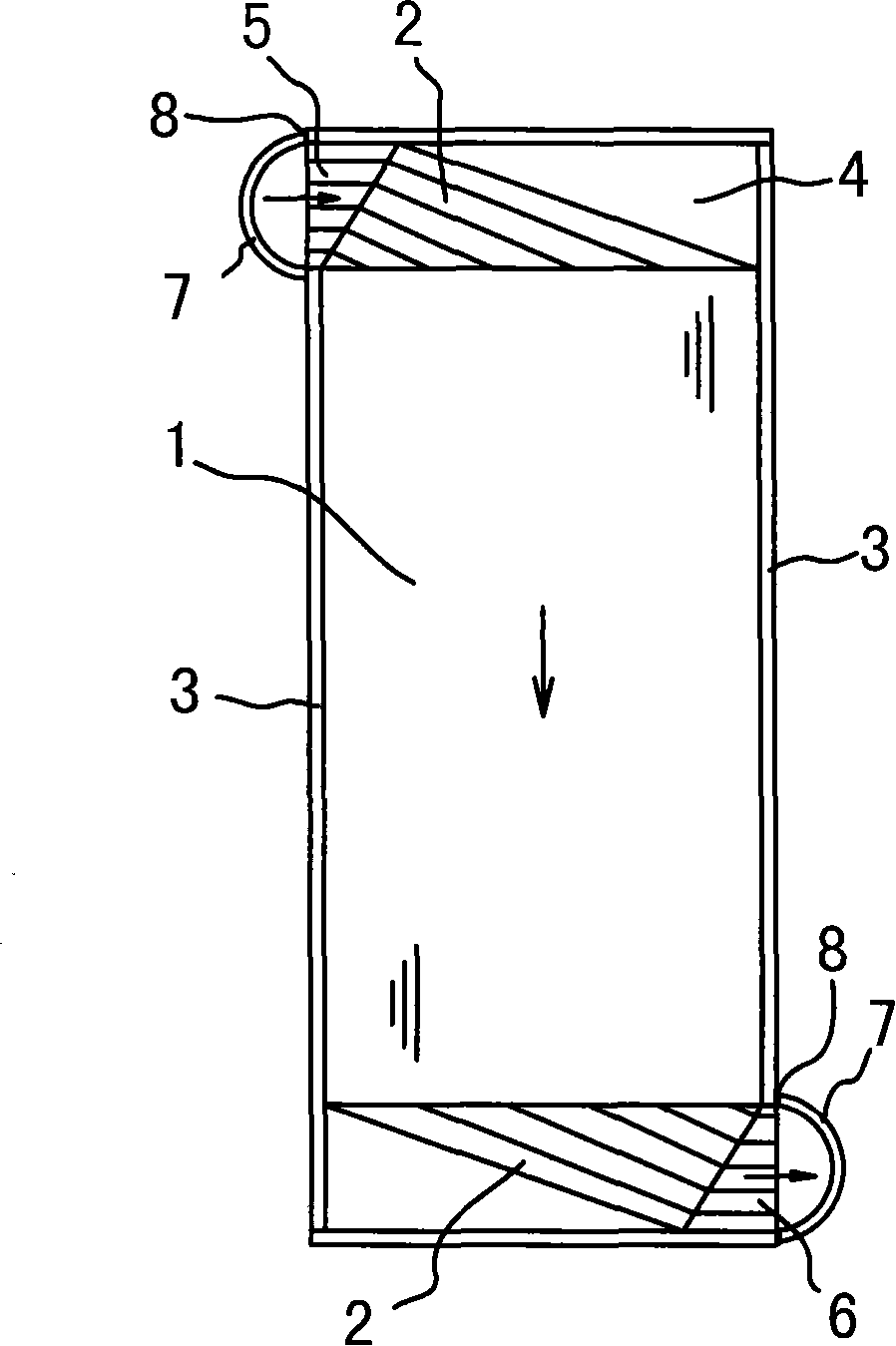

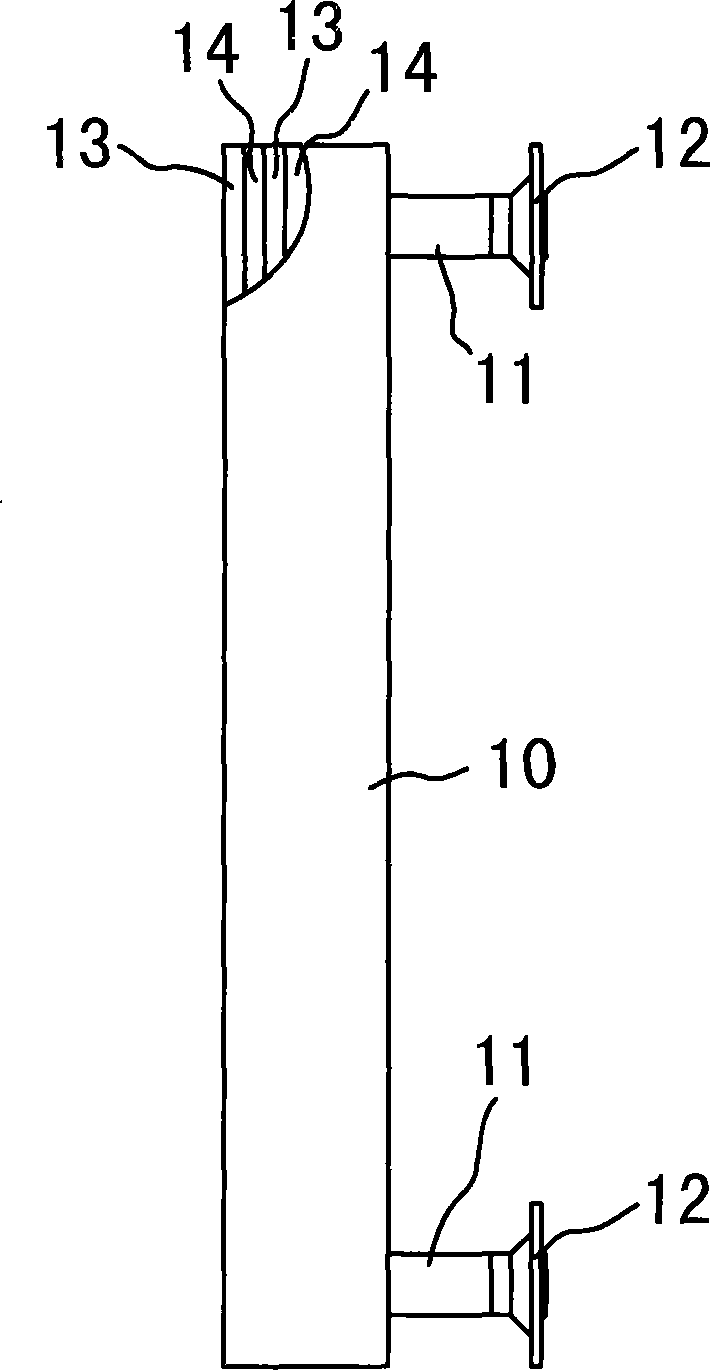

[0038] Embodiment one: see attached image 3 As shown in ~6, a plate-fin heat exchanger is mainly composed of a plate bundle body 10, a connecting pipe 11 and a flange 12. The plate bundle body 10 is composed of two kinds of layer channel units 13 and 14 spaced apart and superimposed in the thickness direction to It is composed of eight layers in total, and the channel units 13 and 14 of these two layers are composed of fins 15 , deflectors 16 , partitions 17 and seals 18 .

[0039] See attached image 3As shown in ~6, at the two ends of the plate bundle body 10, two pairs of fluid inlet and outlet holes are opened through the channel units 13 and 14 of each layer along the thickness direction, wherein:

[0040] See attached image 3 As shown in ~ 6, the first pair of fluid inlet and outlet holes corresponds to the first layer channel unit 13, and the first pair of fluid inlet and outlet holes is composed of a fluid inlet hole 19 and a fluid outlet hole 20, and the fluid inl...

Embodiment 2

[0045] Embodiment two: see attached Figure 7~1 As shown in 2, a plate-fin heat exchanger is mainly composed of a plate bundle body 10, a connecting pipe 11 and a flange 12. The plate bundle body 10 is composed of four layers of channel units 13, 14, 24 and 25 spaced and stacked to a total of eight These four layer channel units 13 , 14 , 24 and 25 are composed of fins 15 , flow guides 16 , partitions 17 and seals 18 .

[0046] See attached Figure 7~1 As shown in 2, four pairs of fluid inlet and outlet holes are opened at both ends of the plate bundle body 10 along the thickness direction through each layer of channel units 13, 14, 24 and 25; wherein:

[0047] Referring to accompanying drawings 9-12, the first pair of fluid inlet and outlet holes corresponds to the first layer channel unit 13, and the first pair of fluid inlet and outlet holes is composed of a fluid inlet hole 19 and a fluid outlet hole 20, and the fluid inlet hole 19 is located on the plate On the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com