Back light source

A technology of backlight source and light guide component, which is applied in the field of backlight source and can solve the problem that the thickness cannot be further reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

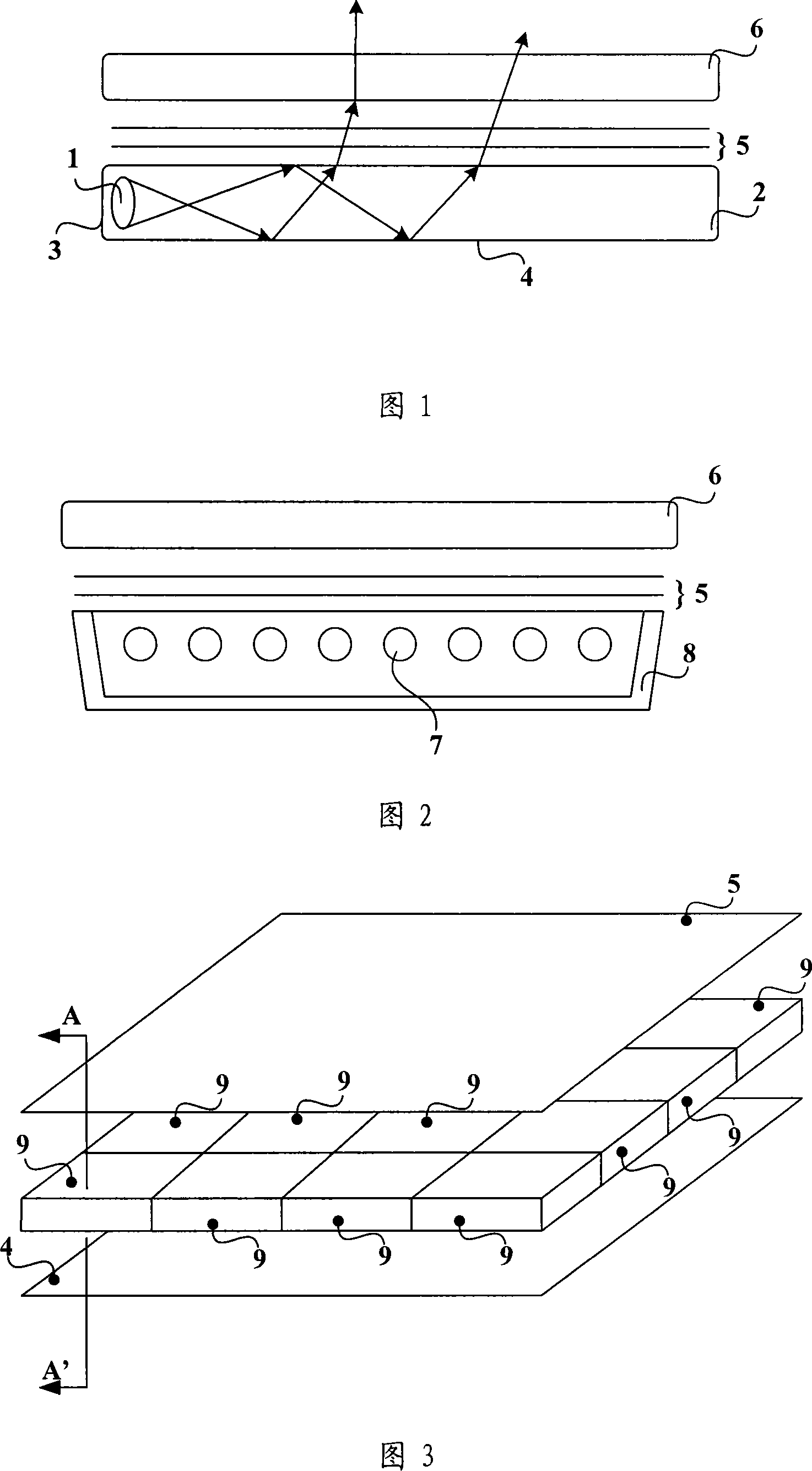

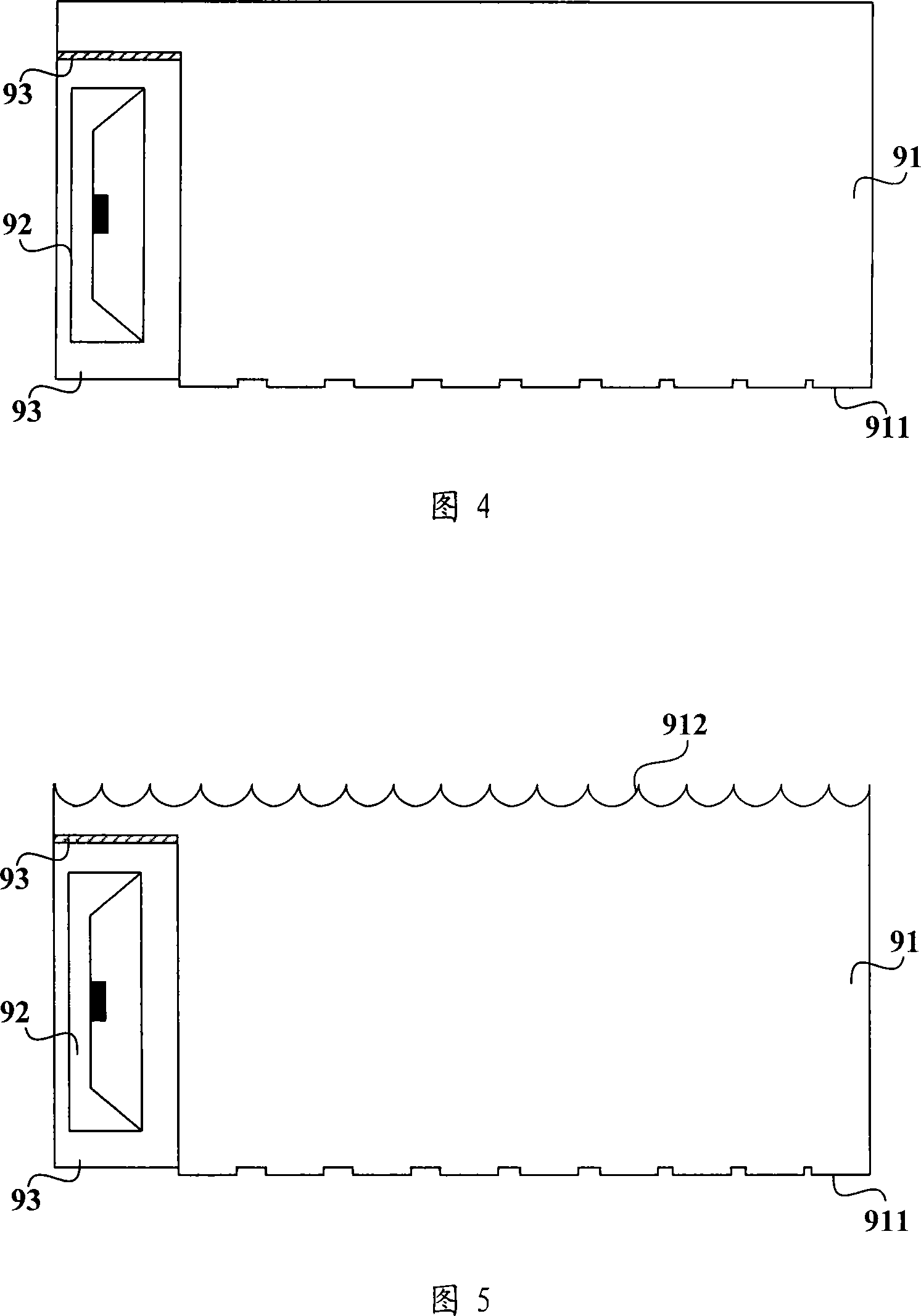

[0023] The backlight in the embodiment of the present invention adopts LED light source, and the mixed light part is divided into several units. Each unit adopts a similar side-light backlight structure, that is, adopts side-light light guide plate technology, and places the The light emitted by the light source is mixed through the light guide plate. Adopting this solution can not only reduce the thickness of the backlight source to the same level as that of the side-light type, but also ensure the high brightness similar to that of the direct-type backlight.

[0024] Each optical unit includes a light guide plate and a light source placed on its side. The light guide plate can be made of materials such as polymethyl methacrylate (PMMA) or polycarbonate (PC), and is made into shapes such as regular square prisms or square prisms with rectangular bottoms by the commonly used injection molding method. Since the shape of the optical unit is mainly determined by the light guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com