Antifogging surface treatment agent and antifogging resin chip

A surface treatment agent and anti-fog technology, which is applied in the direction of synthetic resin layered products, flexible coverings, transportation and packaging, etc., can solve the problems of reduced transparency and no anti-fog properties, and achieve improved anti-fog properties , Excellent transparency and gloss, high anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

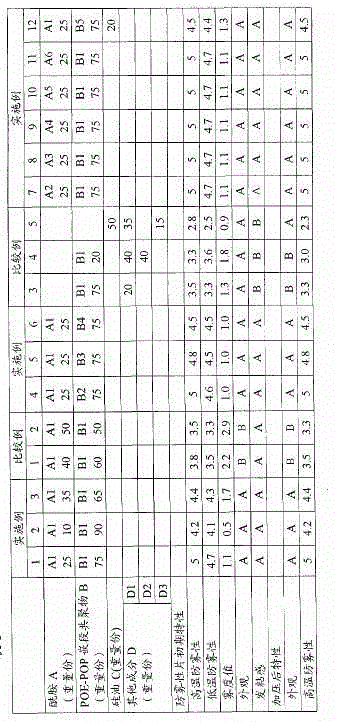

Embodiment 1~12 and comparative example 1~5

[0106] A water-soluble surface treatment agent (anti-fogging treatment agent) containing various components was prepared in the proportions (parts by weight) shown in the table. For a biaxially oriented polystyrene sheet with a sheet thickness of 0.25 mm, use 60 dyn / cm (60×10 -5 N / cm) for corona discharge treatment, the coating amount after drying is 15mg / m 2 The above-mentioned anti-fog treatment agent is coated with a wire brush, and an anti-fog layer is formed after drying.

[0107] The properties of the obtained anti-fog resin sheet (initial properties) and the properties of the resin sheet after laminating the anti-fog resin sheet (post-pressurization properties) were evaluated according to the following methods.

[0108] (1) Initial characteristics of anti-fog resin sheet

[0109] (i) High temperature anti-fog properties

[0110]Put the resin sheet on the opening of the container with hot water at 60°C, make the anti-fog layer of the anti-fog resin sheet come into con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com