Magnetic maintaining electric solenoid with signal feed back

A solenoid and magnetic holding technology, applied in the direction of the electromagnet with armature, electromagnet, valve operation/release device, etc., can solve the problems of poor solenoid protection performance, no action detection feedback signal, etc. Simple, good dustproof, easy to mass-produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

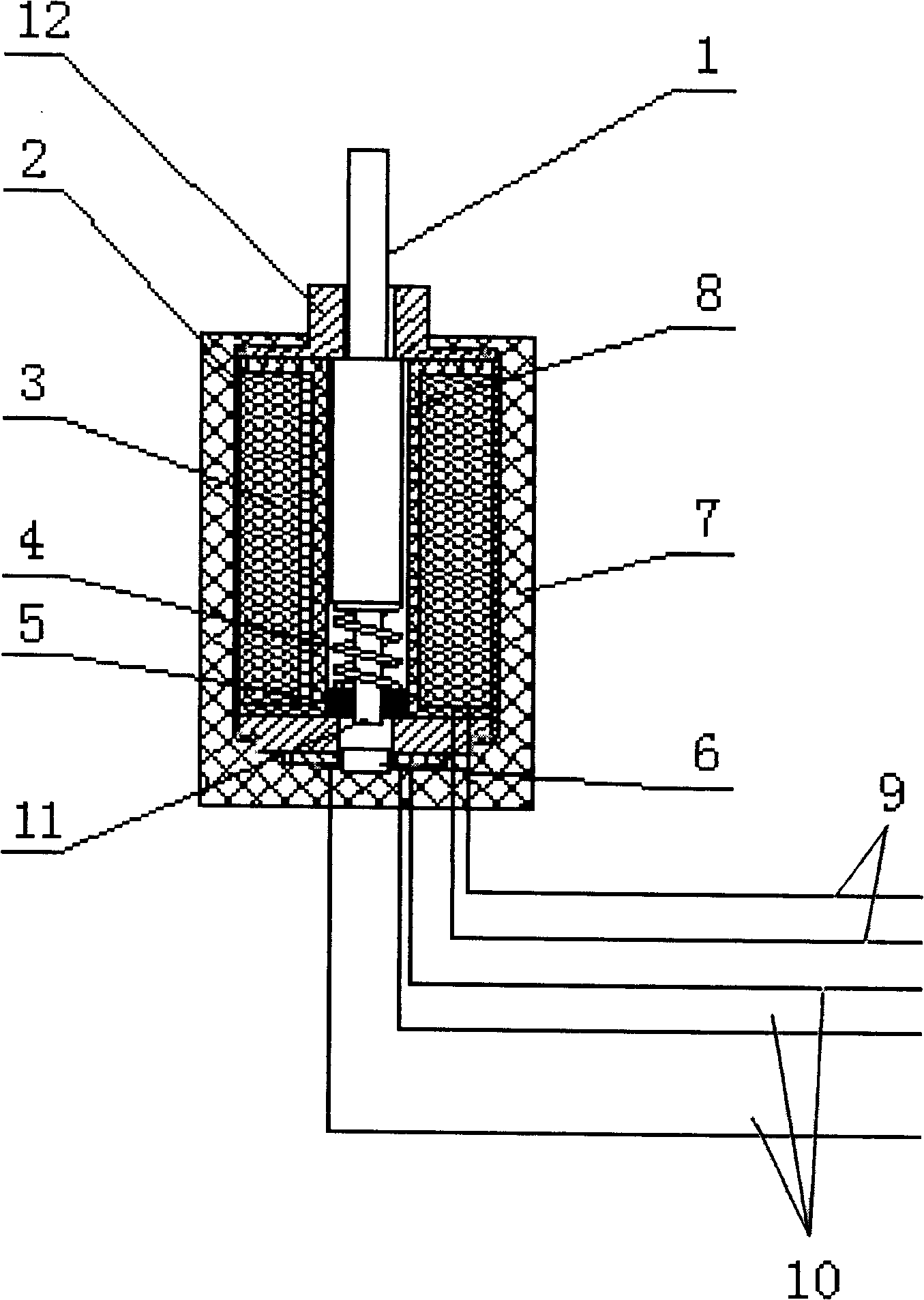

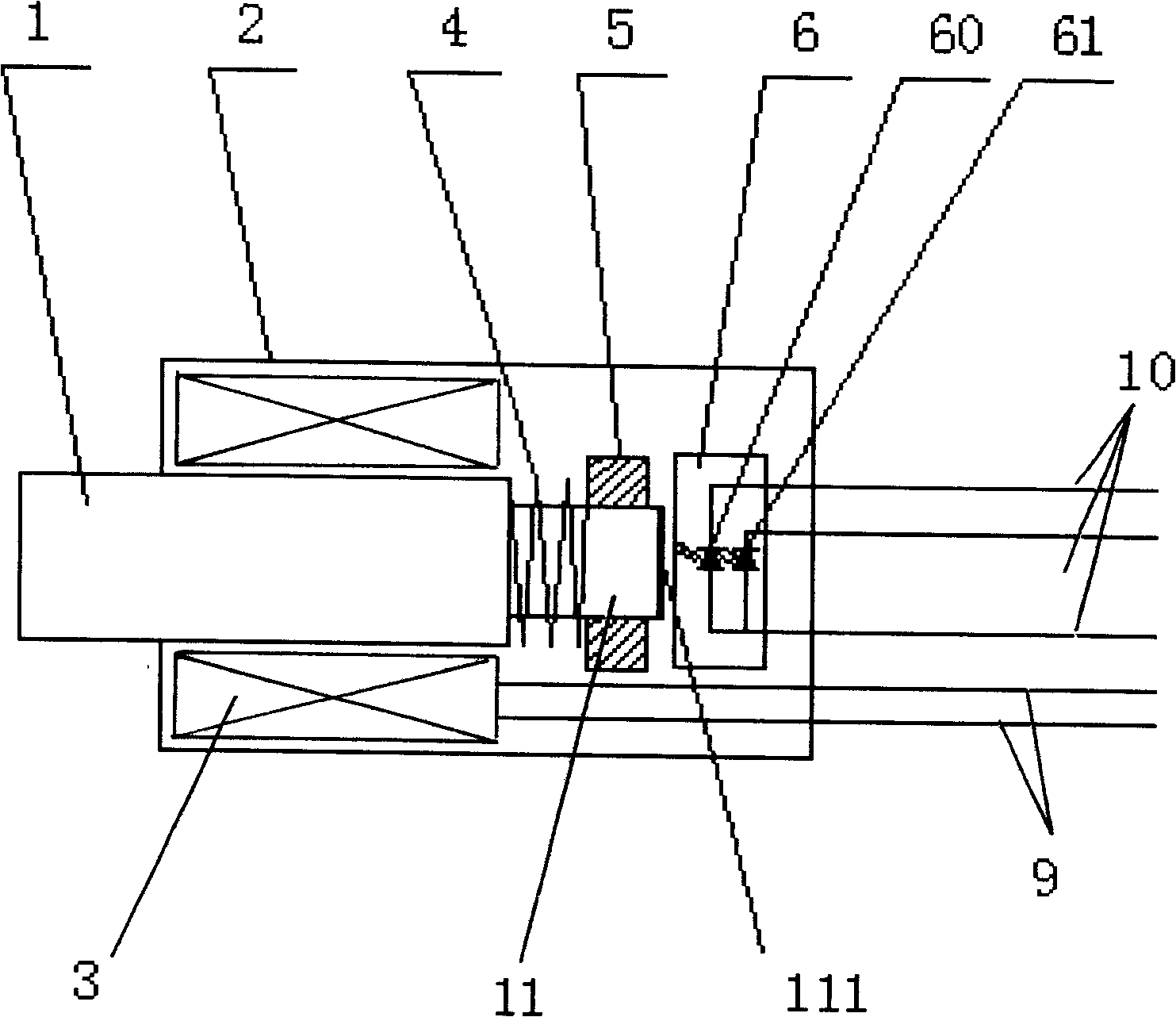

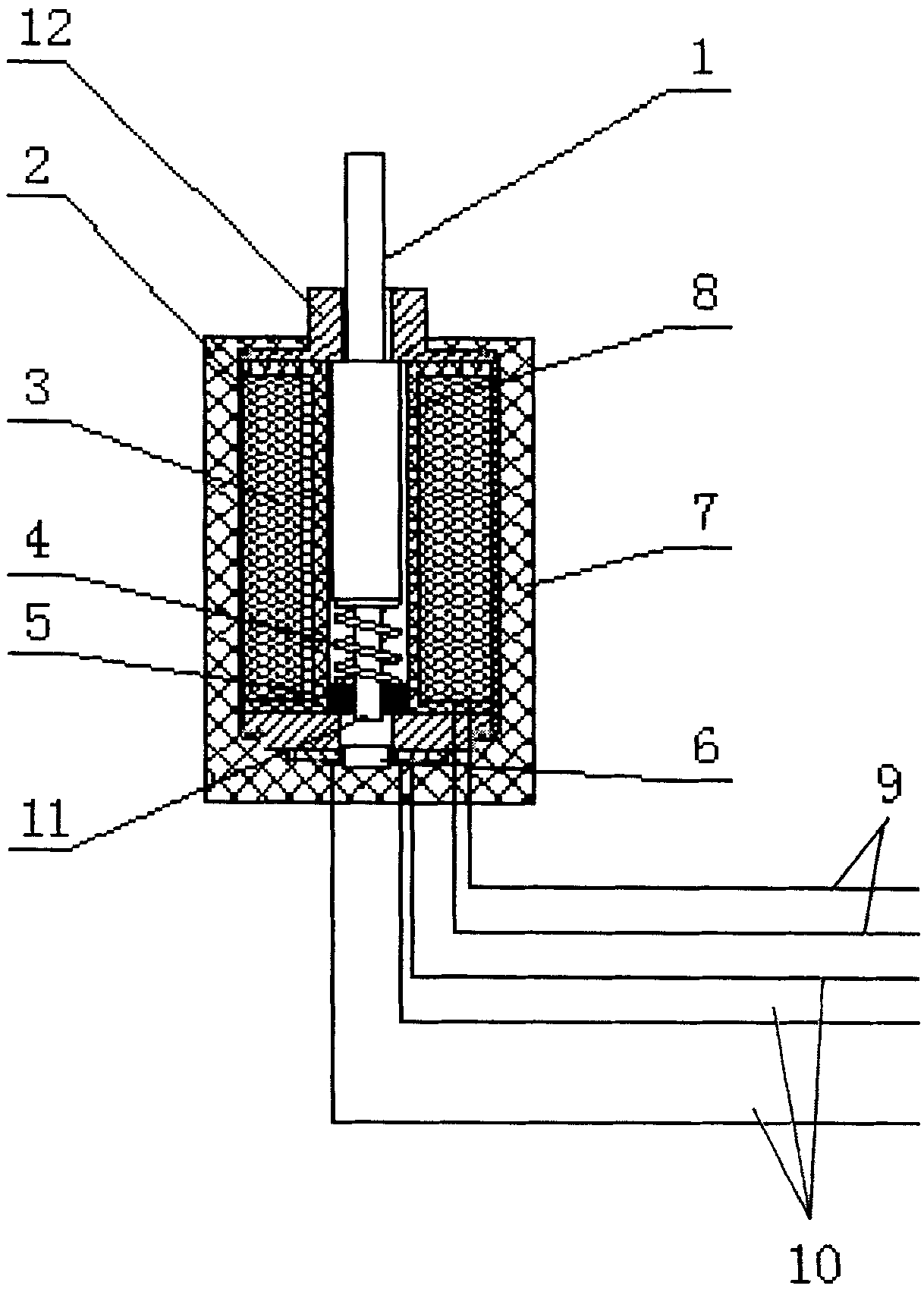

[0017] like figure 1 , figure 2 As shown, a magnetic holding solenoid with signal feedback includes a non-magnetic spool 8, the middle part of the non-magnetic spool is provided with a through hole extending along the axial direction, and the outer circumference of the non-magnetic spool is wound The coil 3; the solenoid also includes a movable iron core 1 movable and freely accommodated in the through hole of the non-magnetic spool, a fixed magnet part 5 for absorbing the movable iron core, and The return spring 4 that pushes the above-mentioned movable iron core to the direction away from the fixed magnet part; wherein, the solenoid also includes a housing 2 that covers the two ends of the non-magnetically conductive bobbin and the side of the coil and is arranged on the housing. 2 and close to the detection circuit 6 of the moving end surface of the movable iron core 1, the detection circuit includes a signal detection device capable of detecting the position of the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com