Accelerator installation adjusting device with compact structure

A technology with installation adjustment and compact structure, which is applied in X-ray equipment, electrical components, material analysis using radiation, etc. It can solve the problems of not meeting the size requirements and achieve the effect of reducing the installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

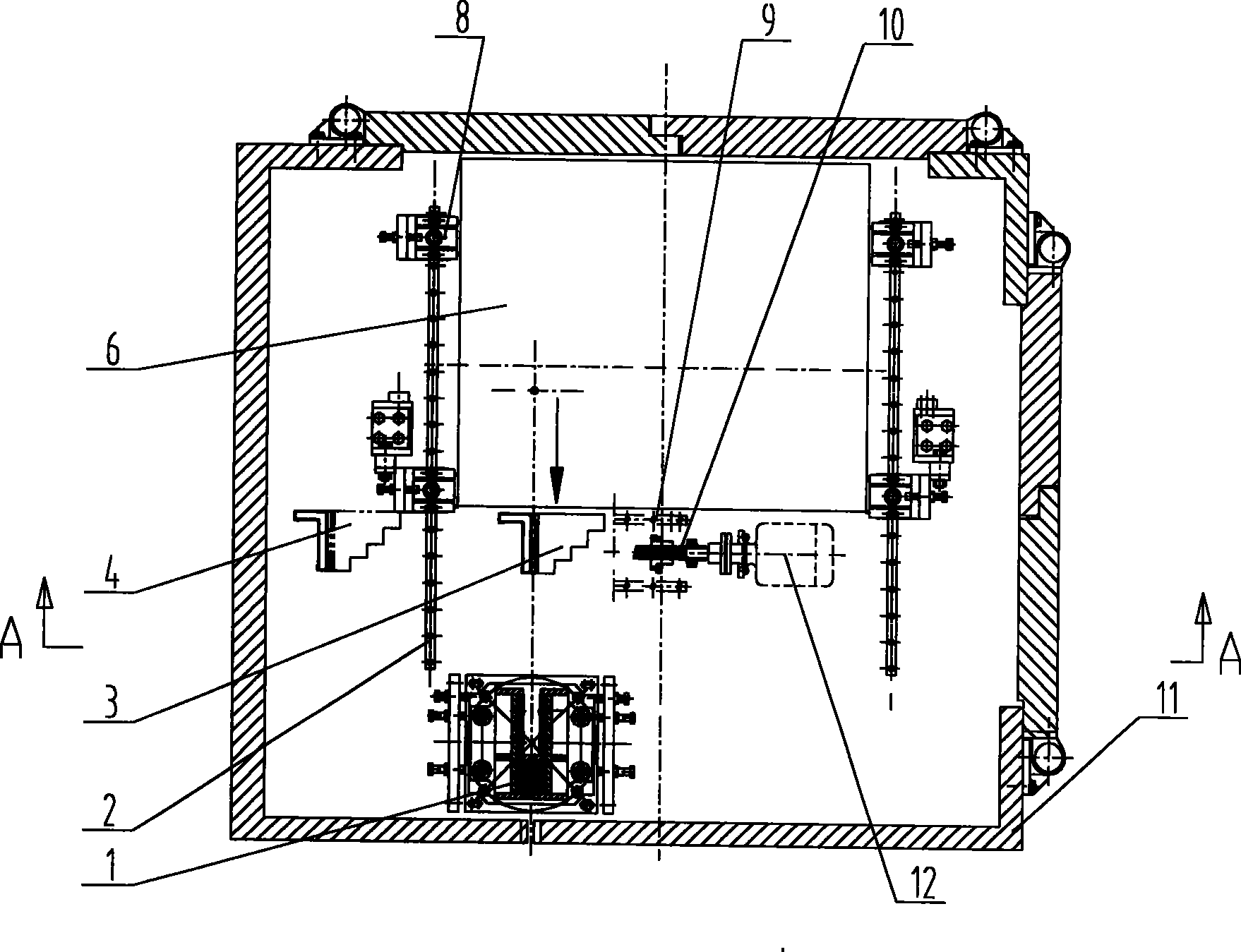

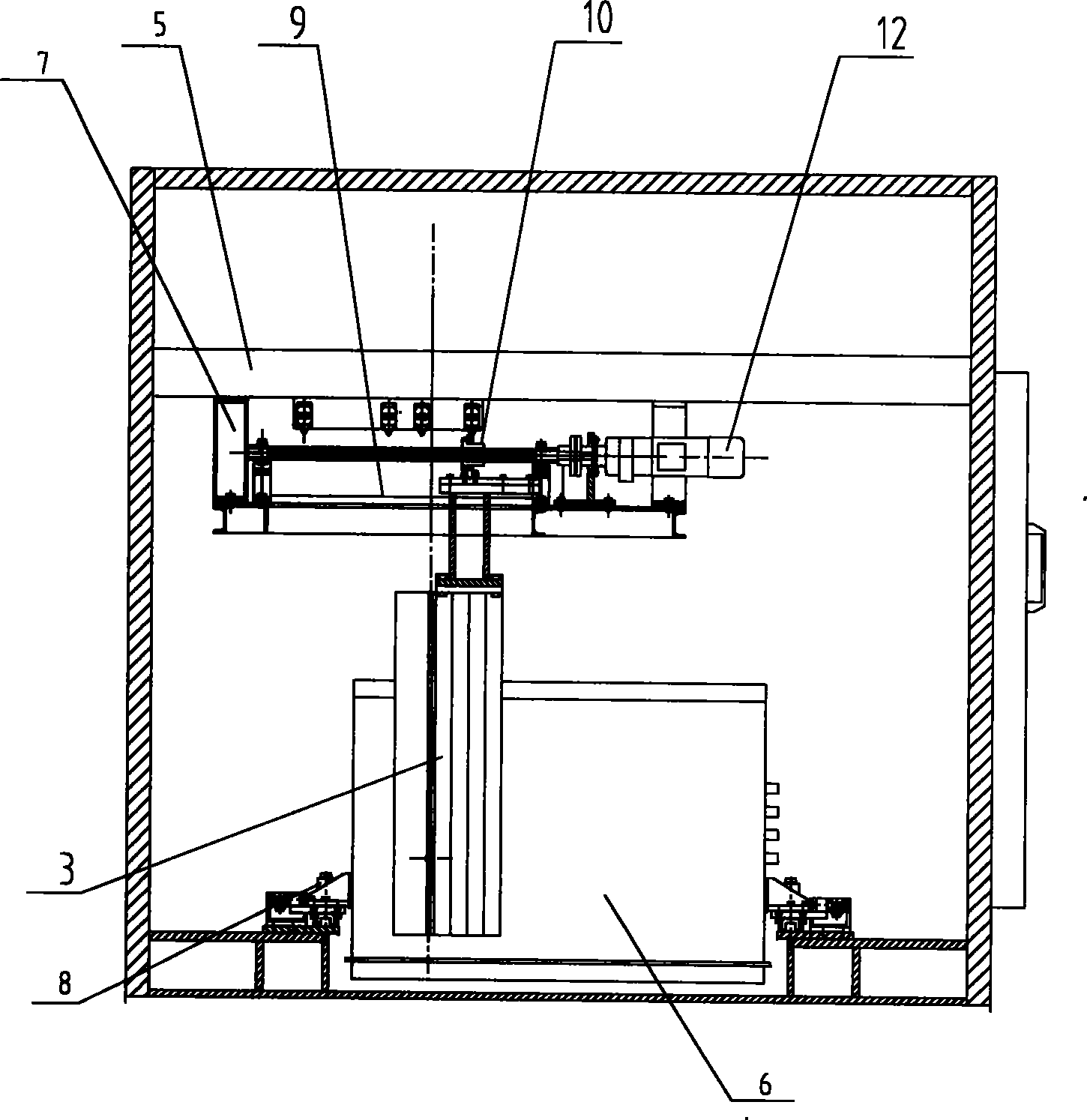

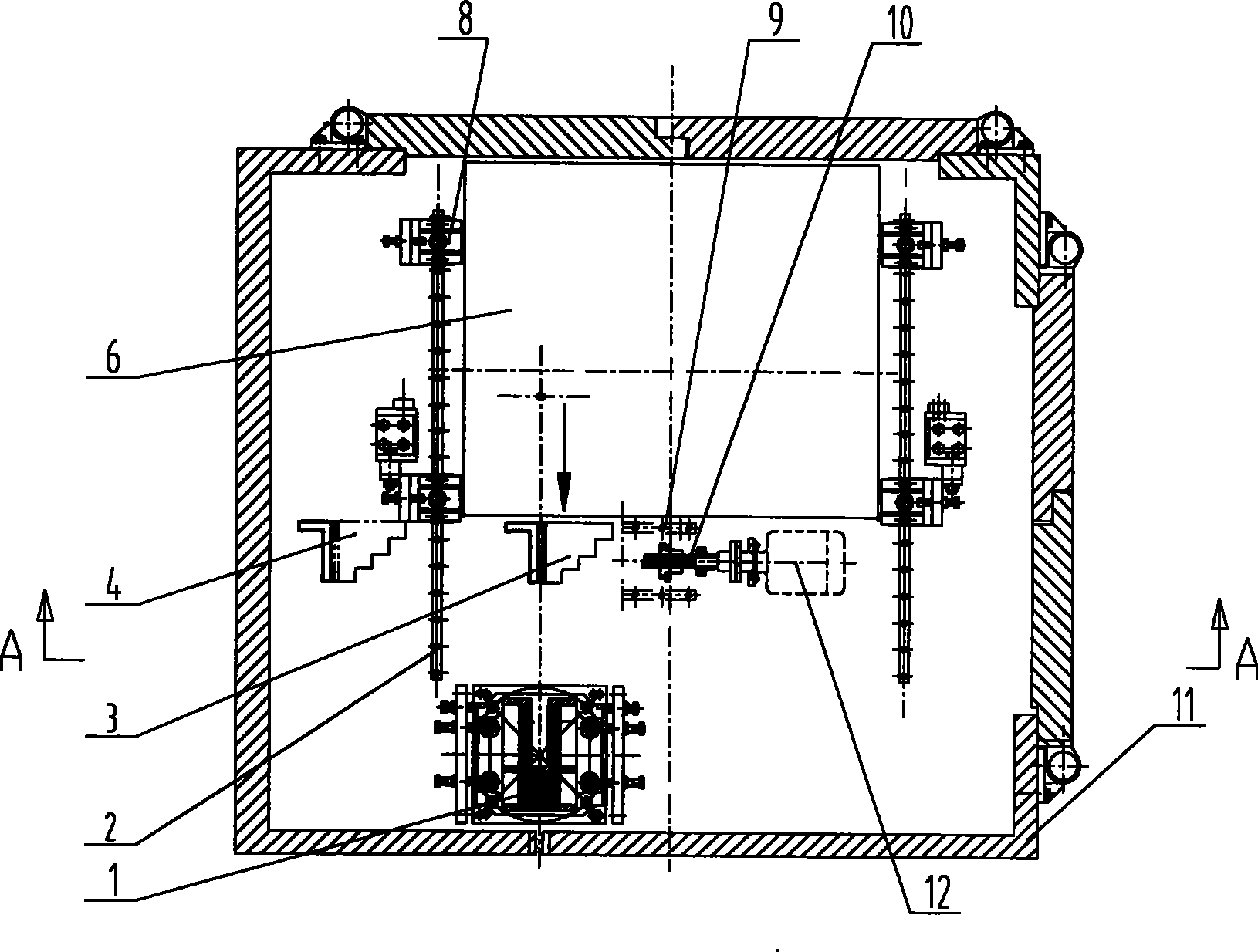

[0011] see figure 1 and figure 2 , the present invention includes a cabin body 11 with a radiation protection function, an accelerator 6 placed in the cabin body 11, a front collimator 3 with a correction block, a rear collimator 1 and a shock absorber for fixing the accelerator 6 for shock absorption. Vibrator 8. Both sides of the bottom of the cabin body 11 are equipped with guide rails 2 placed side by side in a straight line front and back, and adjustable loose shock absorbers 8 are installed on each guide rail 2, and each shock absorber 8 is connected with the accelerator 6. Under normal working conditions, the shock absorber 8 plays a role of fixing the accelerator 6, and the shock absorber 8 plays a buffering role when the accelerator 6 is moved. The accelerator 6 is placed at the back of the cabin body 11 , and its beam output face is facing the rear collimator 1 in front of the cabin body 11 . The top of the cabin body 11 is provided with a moving web 7 . A front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com