Saddle-shaped coil winding using superconductors, and method for the production thereof

A technology of coil winding and saddle coil, applied in superconducting magnets/coils, the usage of superconductor elements, coil manufacturing, etc., can solve the problems of making coil windings that are not very suitable and economical, and avoid excessive elongation and compactness of conductors. effect of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

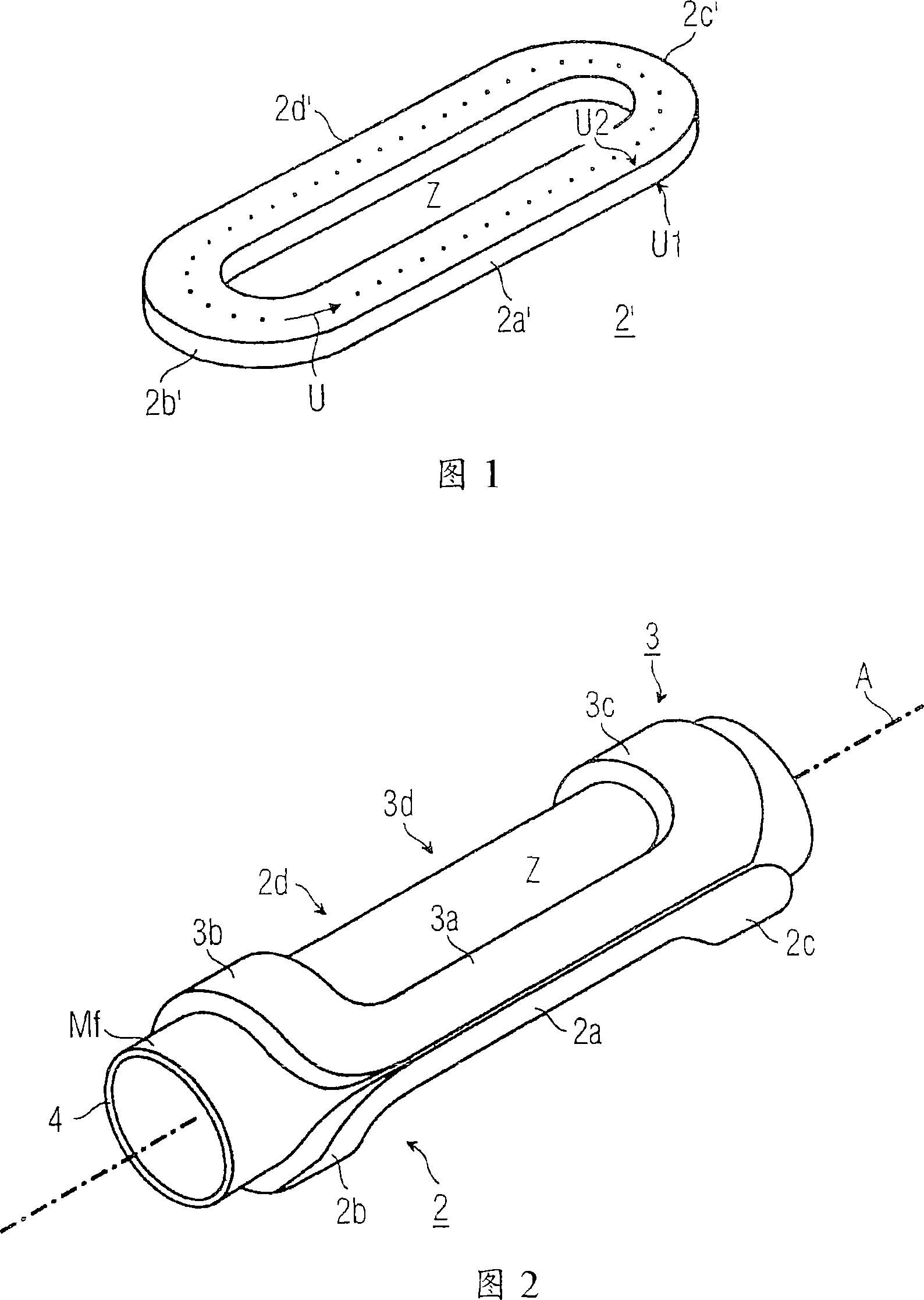

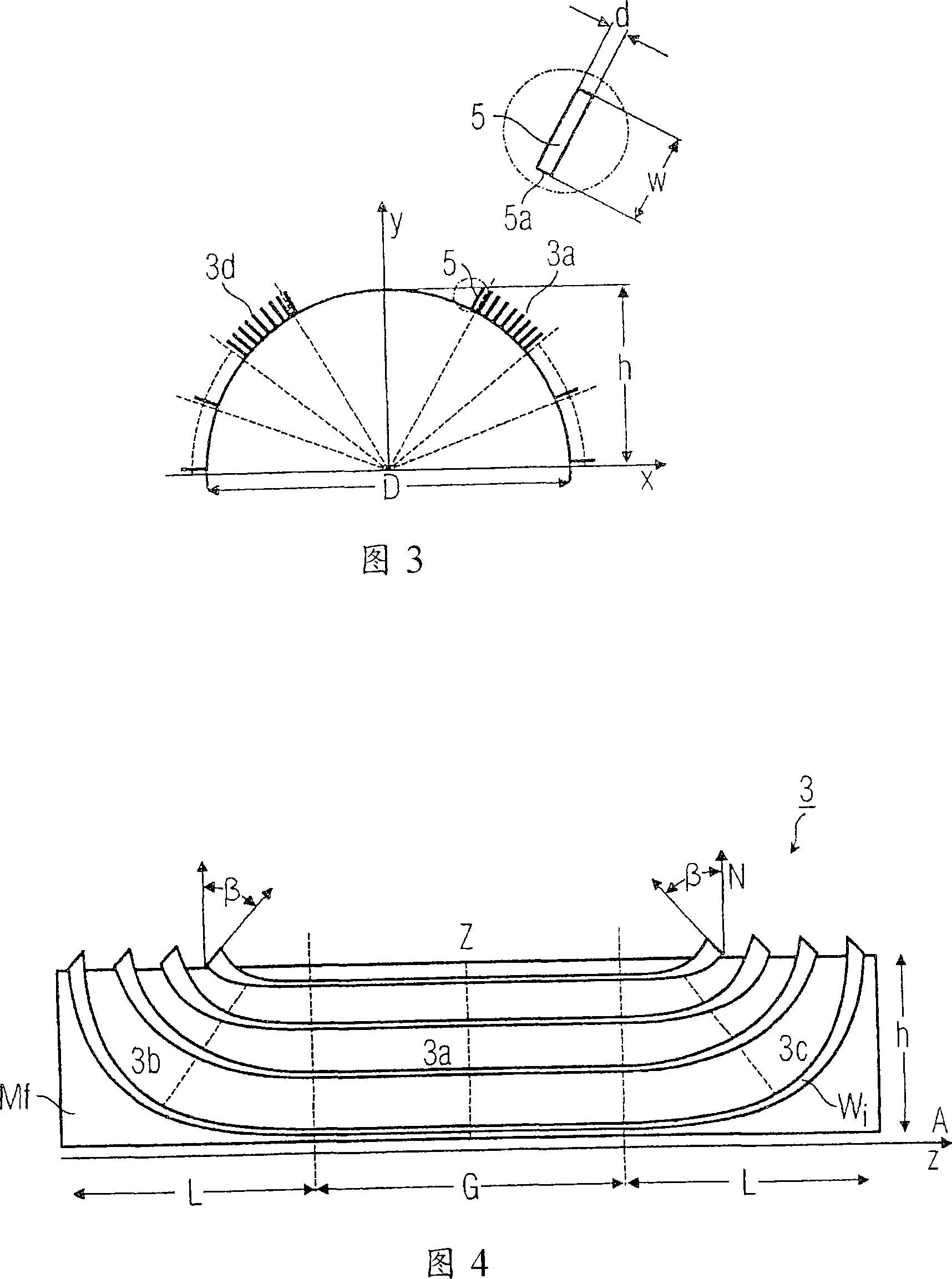

[0044] According to the invention, a planar or flat coil shape of the racetrack type is to be used as the starting point for the production of the saddle coil winding. Corresponding coil shapes are known (see eg DE 199 43 783 A1); FIG. 1 shows an exemplary embodiment. The coil winding denoted there by the reference numeral 2' has opposite longitudinal side winding sections 2a' and 2d' and end-side curved winding sections 2b' and 2c' extending between them. The winding 2' should be made of one or more tape superconductors. To form the coil winding, the respective strip conductor is erected, that is to say wound around the winding center or winding center Z with its narrow side facing the winding plane, for example around a central winding core. In any one turn, one circumference of the conductor should be wound around the center Z once for 360°, or once for each of the two longitudinal side winding sections 2a' and 2d' and the end side winding sections 2b' and 2c', in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com