Precision lifting device

A precise and driving device technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of large focusing and leveling components and limited installation space, and achieve the effect of large lifting height, stable lifting and high resolution of height value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

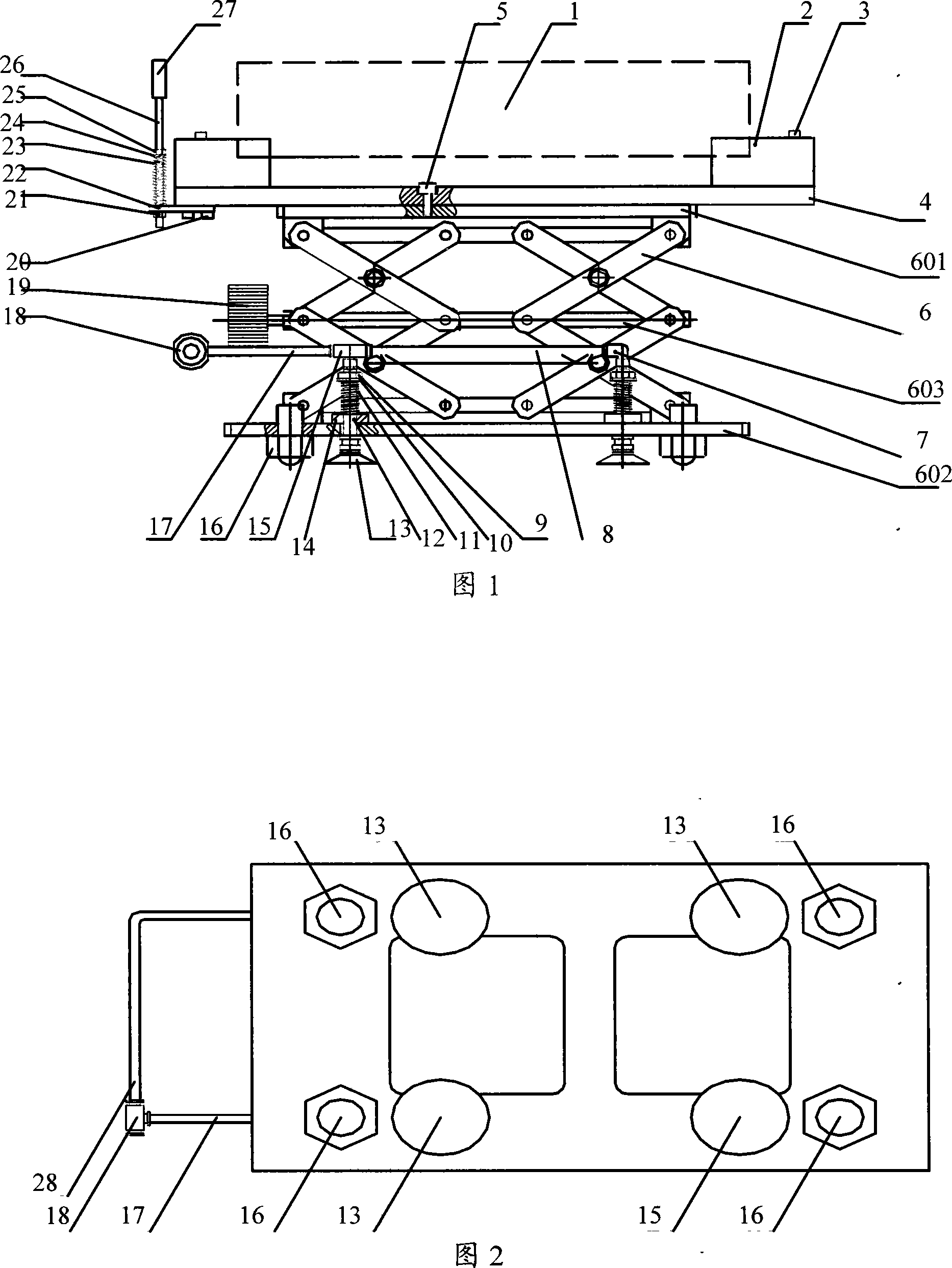

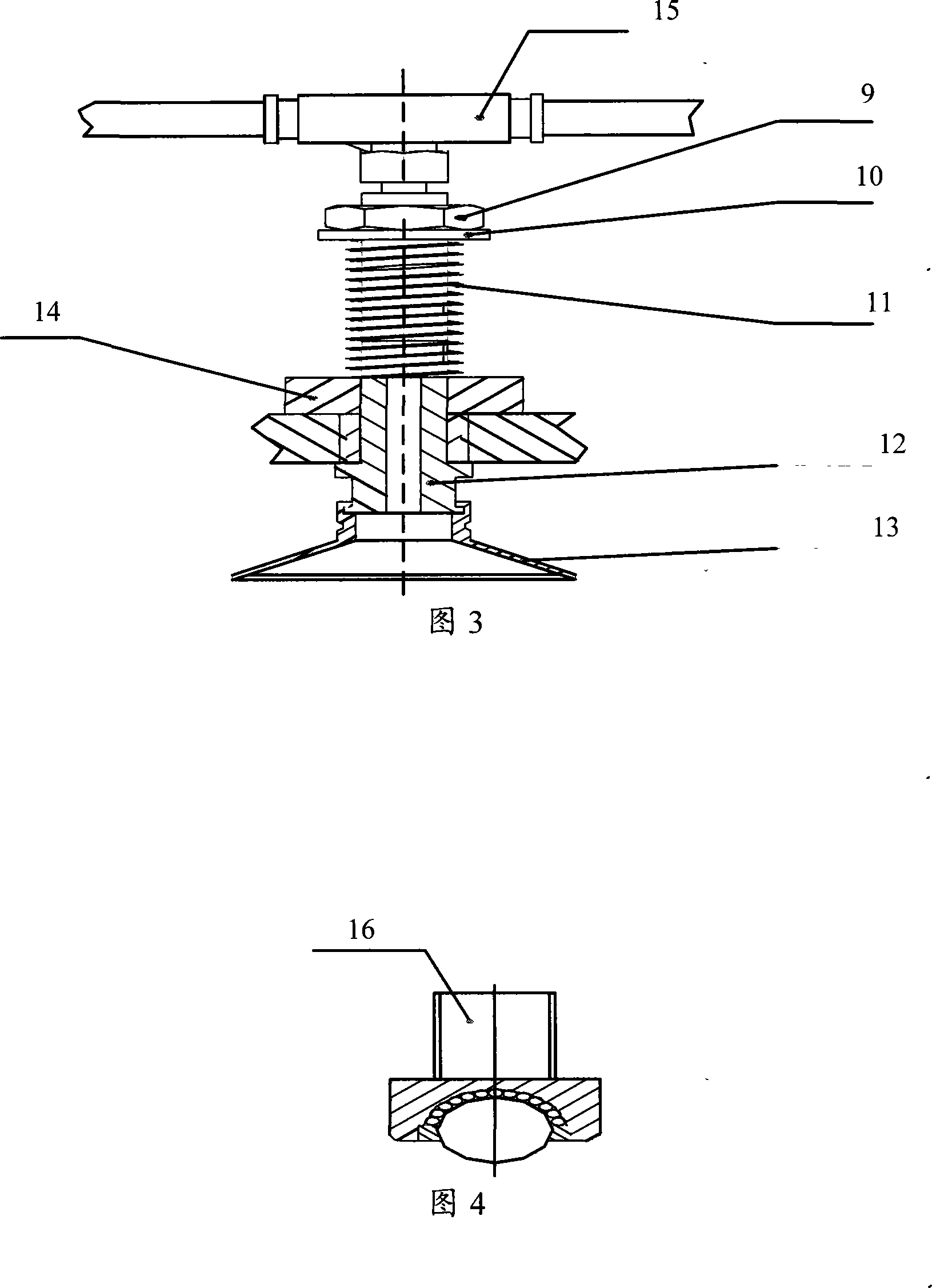

[0021] Below in conjunction with the accompanying drawings, a precision lifting device of the present invention will be further described:

[0022] As shown in Fig. 1, the present invention includes a positioning block 2, a bearing plate 4, a lifting mechanism 6, a steel ball roller mechanism 16, a hand wheel 19, a vacuum adsorption mechanism, and a height limiting mechanism.

[0023] Positioning block 2 utilizes screw 3 to be fixed on the two ends of bearing plate 4, and bearing plate 4 utilizes screw 5 to be installed on the upper panel 601 of lifting mechanism 6, and the height limiting mechanism is fixed on one end of bearing plate 4.

[0024] The lifting mechanism 6 is composed of more than two lifting units connected in parallel, the lifting units are connected by two X-shaped trusses through hinges, and the driving device is assembled at the joints of the hinges.

[0025] Wherein the height limiting mechanism comprises: a spring 23, a gasket 24, a nut 25, a screw rod 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com