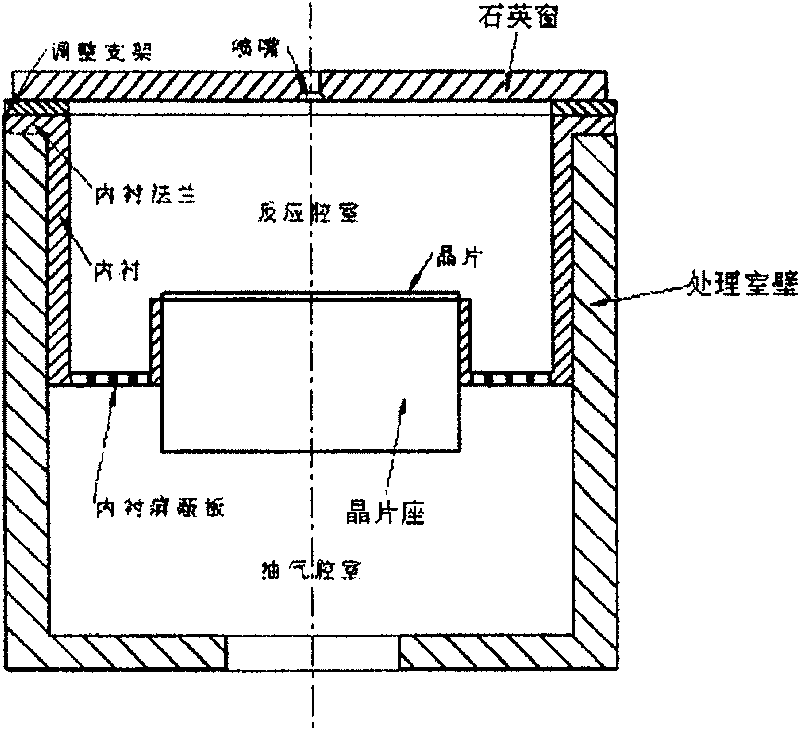

Wafer processing chamber liner and wafer processing chamber comprising same

A wafer processing and lining technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of thin film formation, inability to effectively protect and adjust the bracket, and narrow protection range, so as to improve productivity and reduce downtime. Cleaning time, extended protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

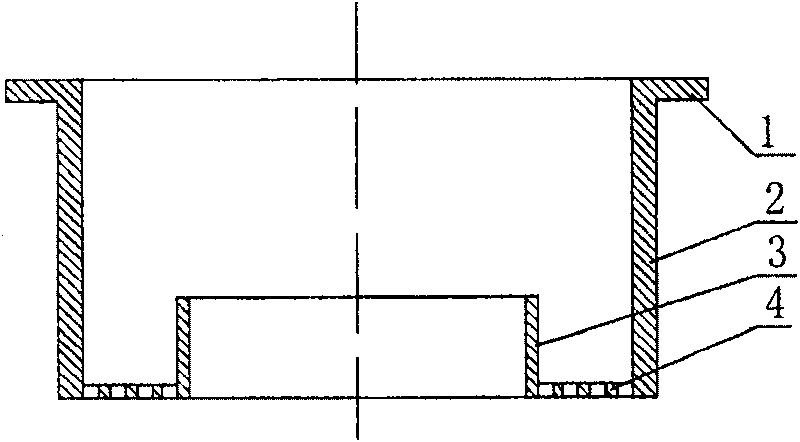

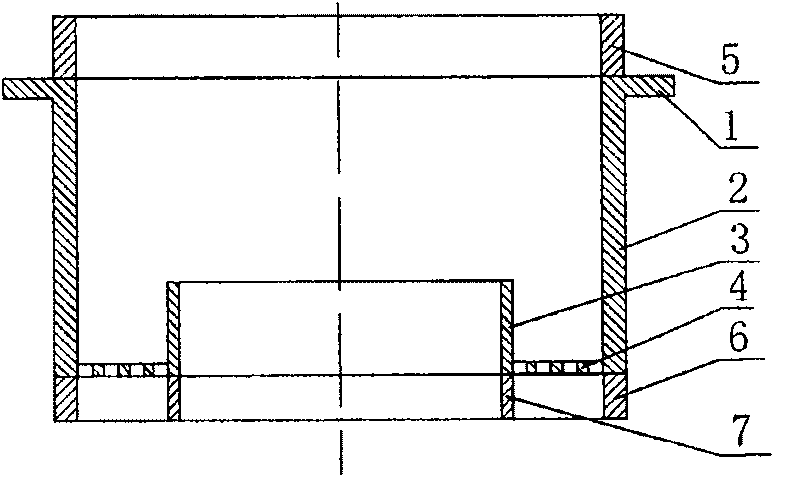

[0025] The preferred embodiment of the lining of the wafer processing chamber of the present invention is as image 3 As shown, it includes an inner wall 3 and an outer wall 2, the inner wall 3 and the outer wall 2 are connected by a shielding plate 4, the upper edge of the outer wall 2 is connected with a flange 1, and the edge of the side wall is connected with an extension part.

[0026] The extension part includes an upwardly extending part 5 of the upper edge of the outer wall 2, which is located above the upper surface of the flange 1, and is used to protect the adjustment bracket at the lower part of the quartz window. This part preferably extends upwards to the quartz window, which provides sufficient protection for the adjustment bracket.

[0027] The extended portion also includes a downwardly extending portion 6 of the lower edge of the outer sidewall 2, located below the shielding plate 4, for protecting the processing chamber wall of the pumping chamber.

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com