A laminated multi-layer flexible printed circuit board and its making method

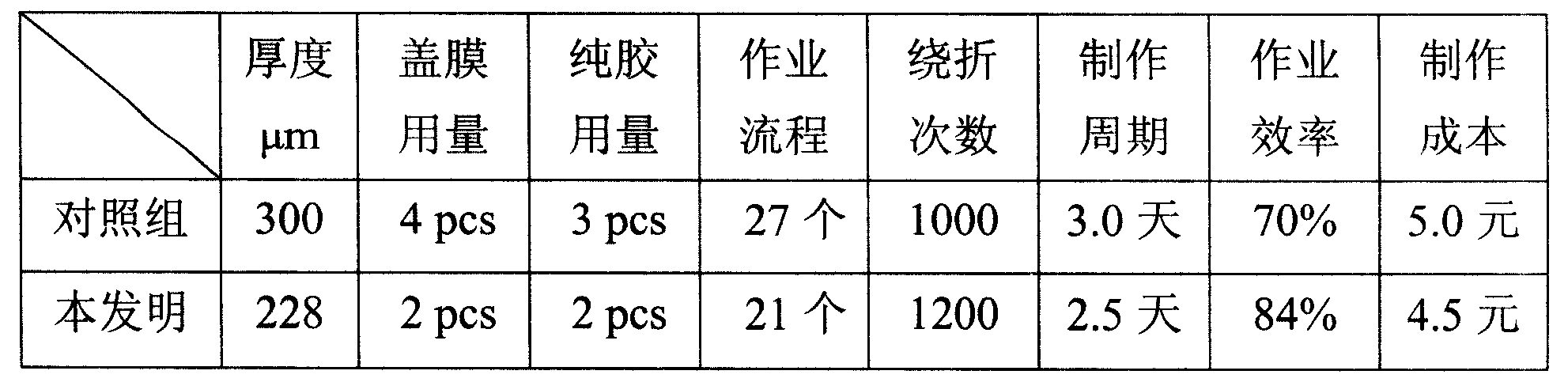

A technology of flexible printing and manufacturing methods, applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems of product total side thickness, poor folding performance, high material cost, etc., to achieve enhanced folding performance, The effect of improving production efficiency and shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

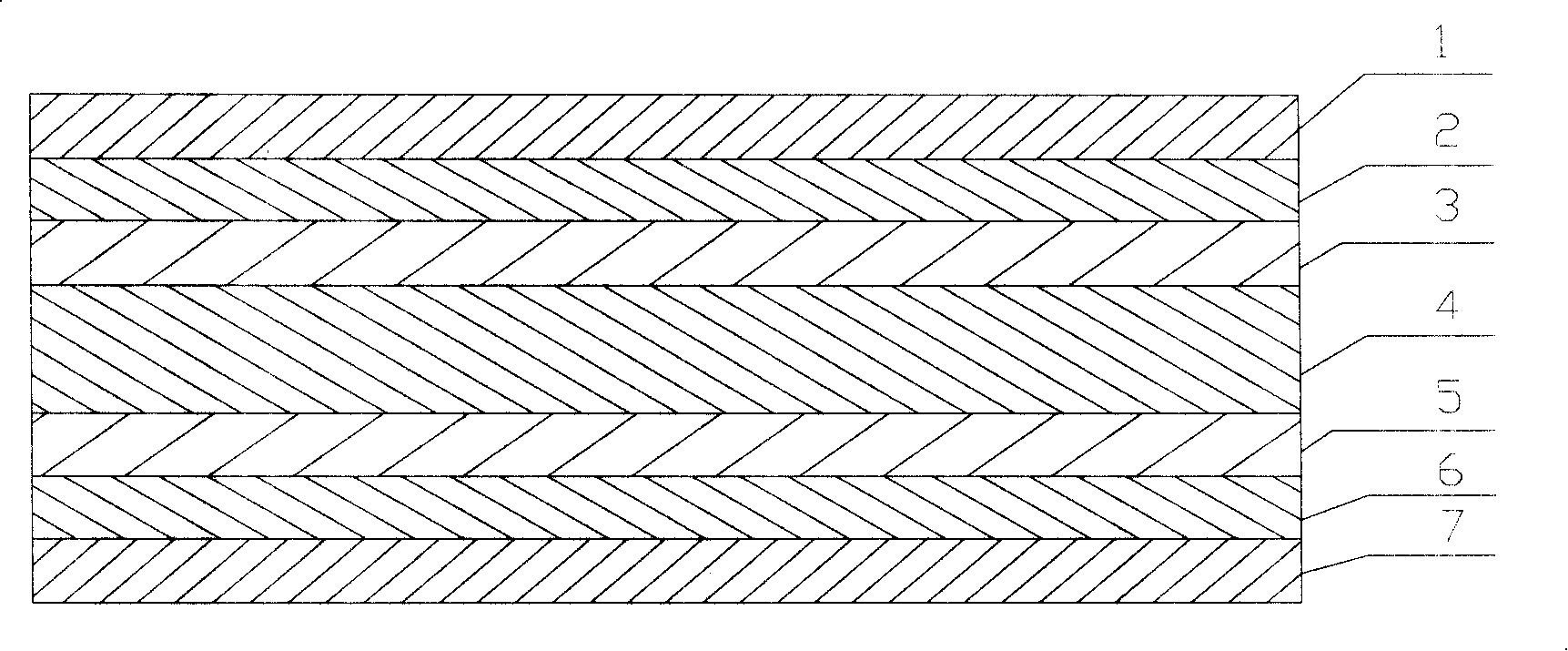

[0023] A laminated four-layer flexible printed circuit board and a manufacturing method thereof.

[0024] The laminated four-layer flexible printed circuit board as shown in the drawings includes the outermost two layers of single-sided boards 2, 6 and the cover films 1, 7 respectively attached to their outer surfaces, and also includes the middle layer through semi-cured Glue 3, 5 is directly laminated with etched double-sided board 4 with lines. It has the following steps in order:

[0025] Double-sided material cutting→one-time drilling→surface cleaning treatment→applying photosensitive film on double-sided surface→exposure and development→line etching→removing photosensitive film→attaching prepreg→attaching the outermost two layers of single-sided panels→combining hot pressing→ Secondary drilling→drilling blackening treatment→copper plating of multi-layer board→coating photosensitive film on copper surface→re-exposure and development→re-line etching→removing photosensitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com