Molding apparatus and molding method using a transfer film

A technology of transfer mold and film, which is applied in the field of transfer molding devices, can solve problems such as deceleration, and achieve the effects of increased film feed speed, film vibration elimination, relaxation and vibration elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

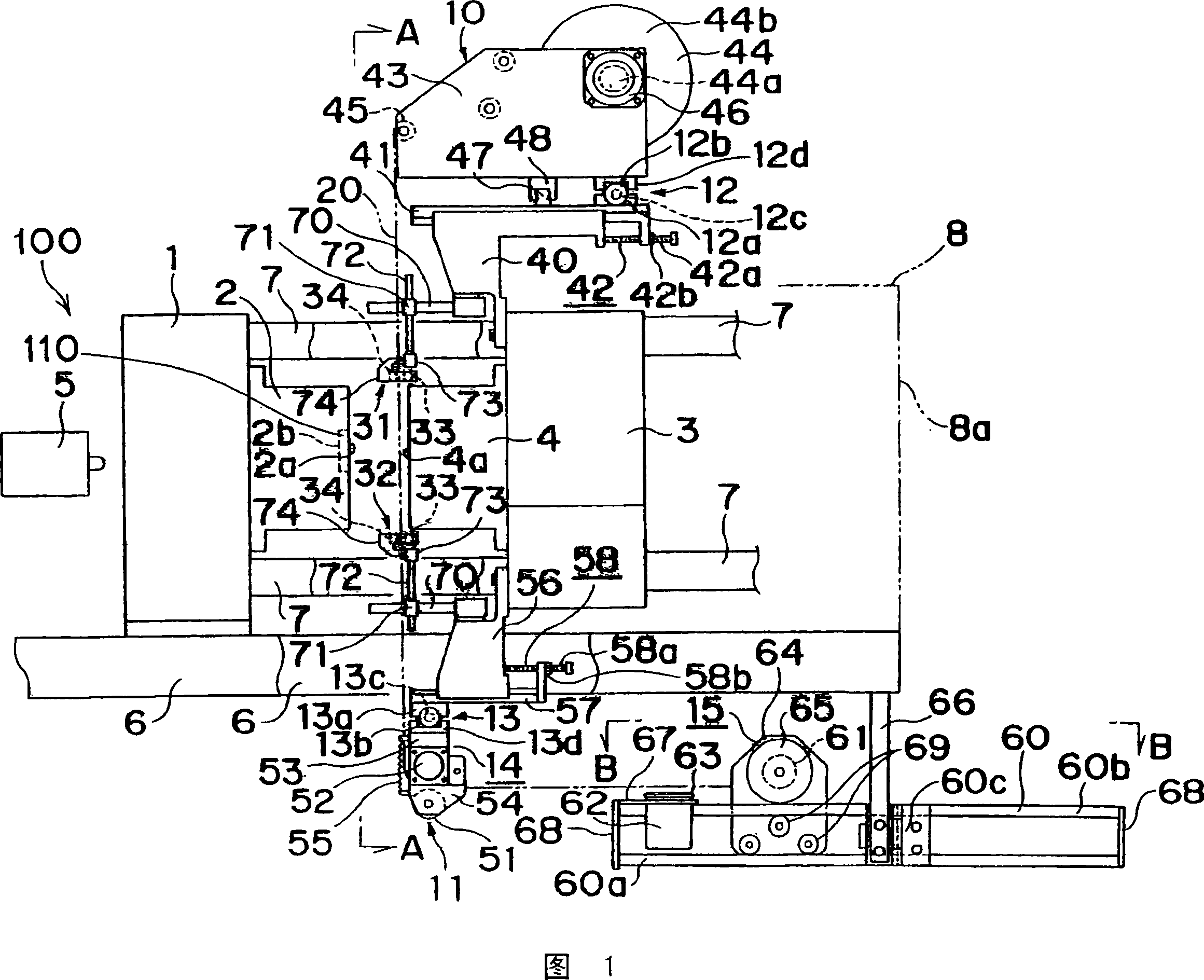

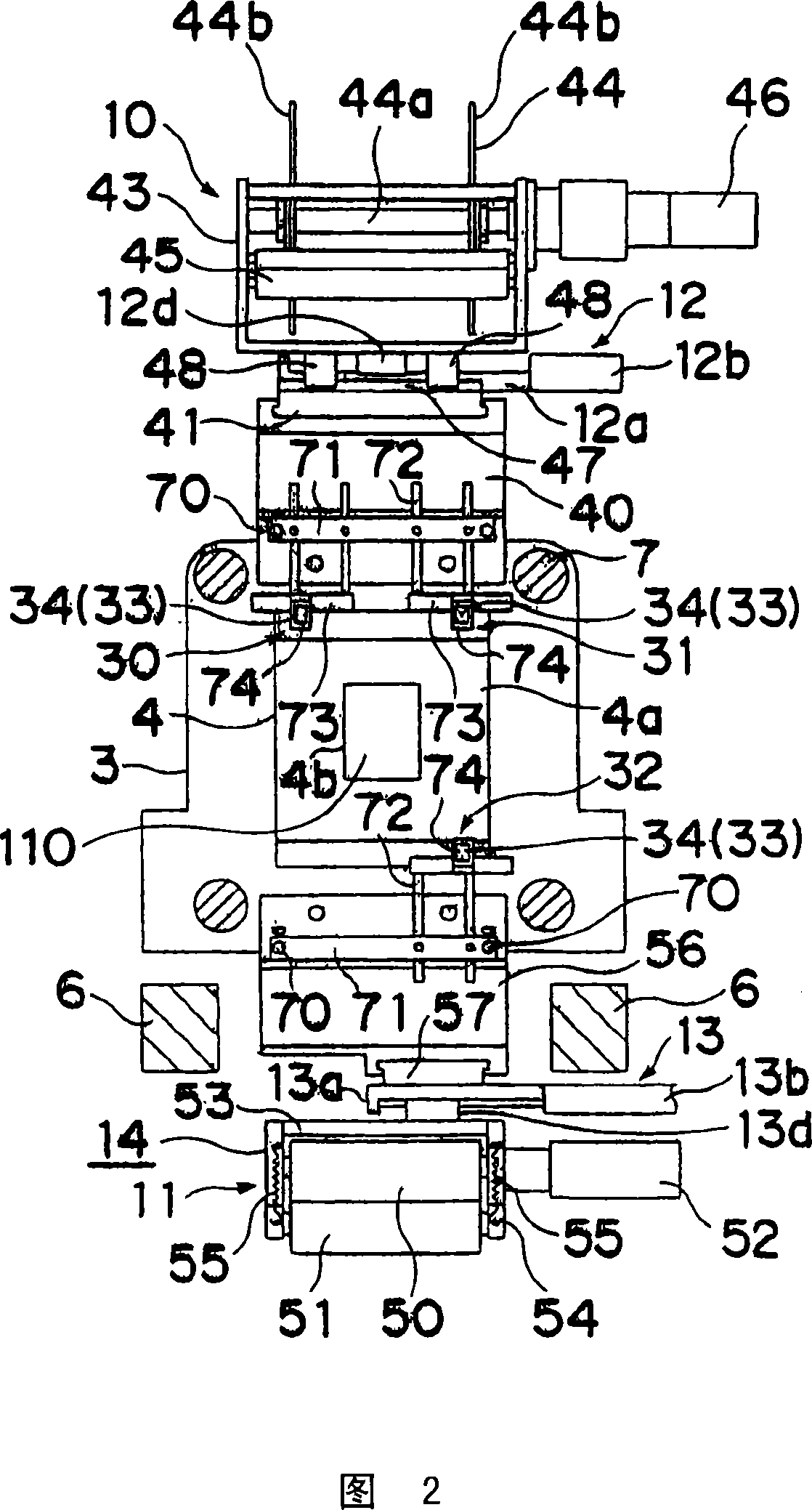

[0081] Before proceeding to describe the present invention, it is noted that like parts are indicated by like reference numerals throughout the drawings. A first embodiment according to the present invention will be described in detail below with reference to the accompanying drawings.

[0082] As shown in Figures 1 and 2, the transfer molding device has a transfer molding part 100, which includes a fixed mold 2 installed on a fixed base 1, a movable mold 4 installed on a movable base 3, and a mold for melting The resin is injected into the injection nozzle 5 formed in the cavity between the two molds 2,4.

[0083] In the transfer molding apparatus according to this embodiment, the fixed base 1 is fixed to the base 6, and the movable base 3 is guided and moved by four tie rods 7 fixed to the fixed base 1 so as to approach and move away from the fixed base 1.

[0084]By means of the movement of the movable base 3, it is possible to switch between the closed state and the open ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com