Metal halide lamp

A metal halide lamp and halide technology, which can be applied to discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problems of low luminous efficacy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

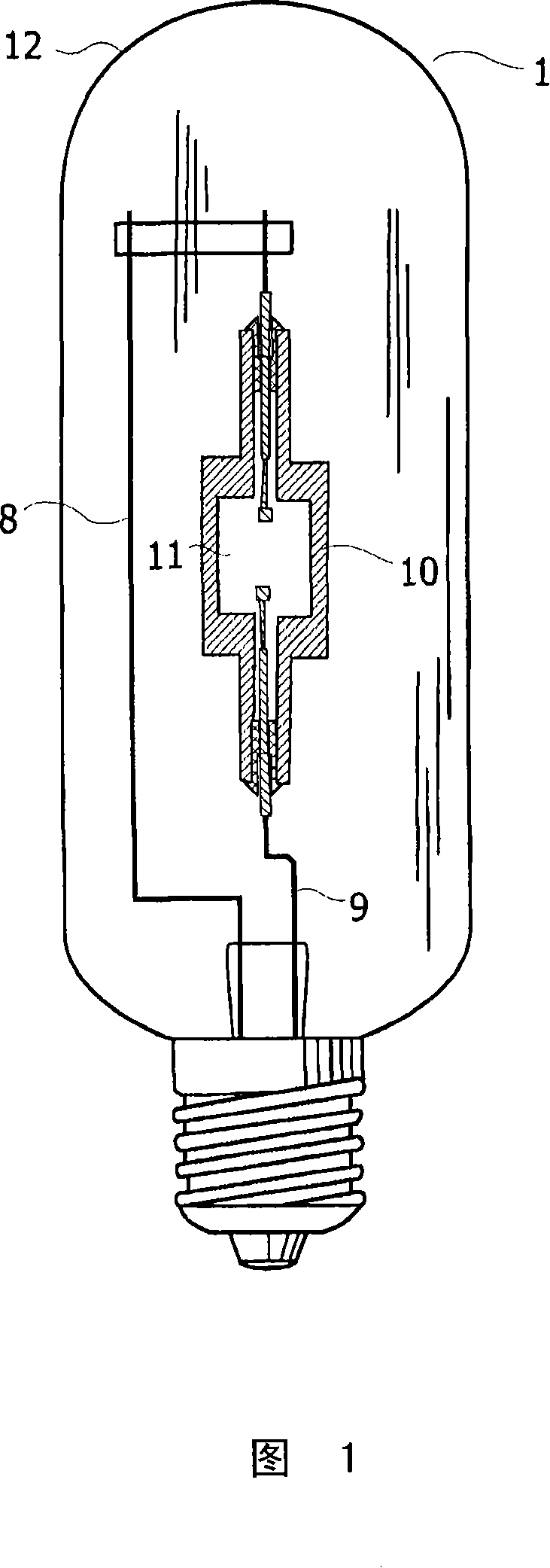

[0016] Fig. 1 shows a metal halide lamp 1, which comprises a discharge vessel 10, which is shown in cross-section and not to scale in Fig. 2, and which has a closed discharge space 11 The ceramic wall, the discharge space 11 contains ionizable fillers, in addition to Hg, the fillers also include NaI, CaI 2 , CeI 3 And MgI 2 .

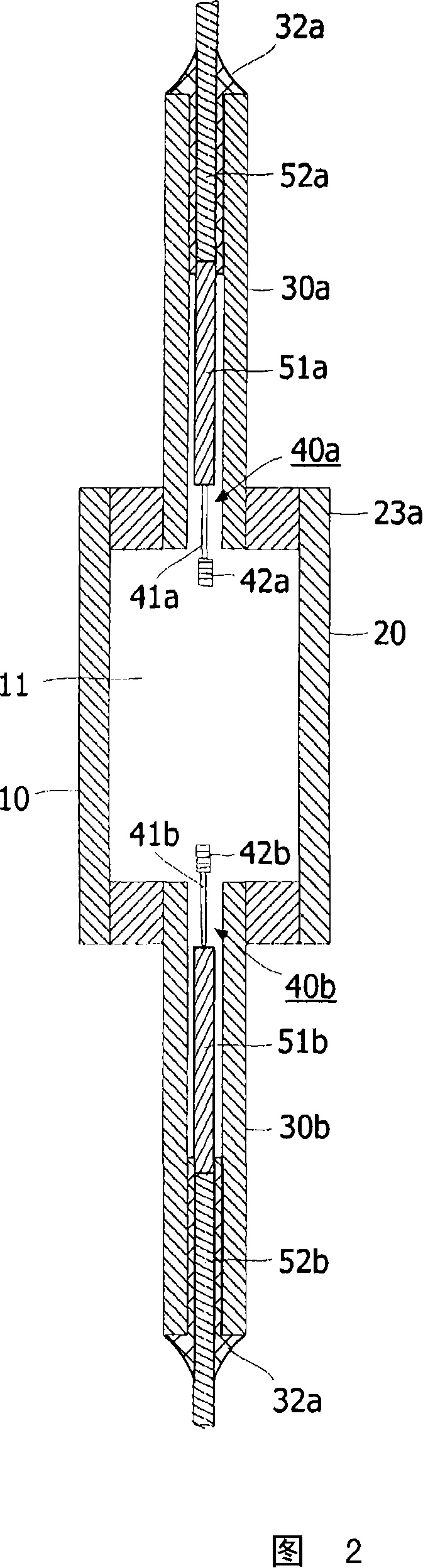

[0017] Figure 2 shows the discharge vessel in detail. The discharge vessel has a ceramic wall 20 which is provided with protruding ceramic plugs 30a, 30b at either end to accommodate the electrical lead-in wires to the electrodes 40a and 40b, respectively. Each lead-in line includes anti-halide parts 51a, 51b and parts 52a, 52b, for example, the parts 51a, 51b are made of Mo, and the parts 52a, 52b are connected in an air-tight manner through, for example, ceramic glaze connections 32a, 32b. To the plugs 30a, 30b. In this specification, anti-halide is understood to mean that there is no or substantially no corrosive damage caused by halides, and no halogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com