Substrate processing platform allowing processing in different ambients

A substrate and processing chamber technology, applied in the field of semiconductor processing equipment, can solve problems such as long delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

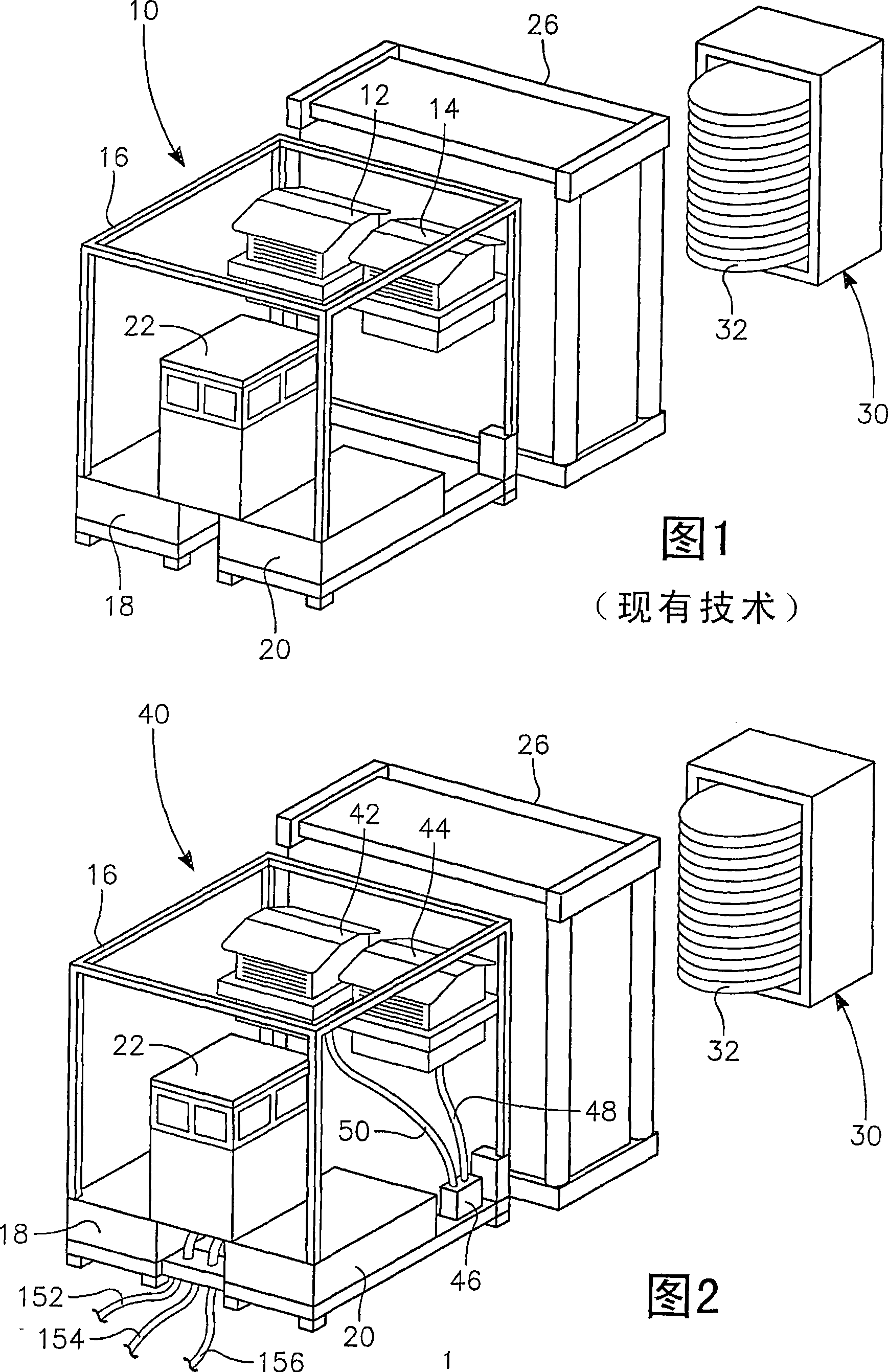

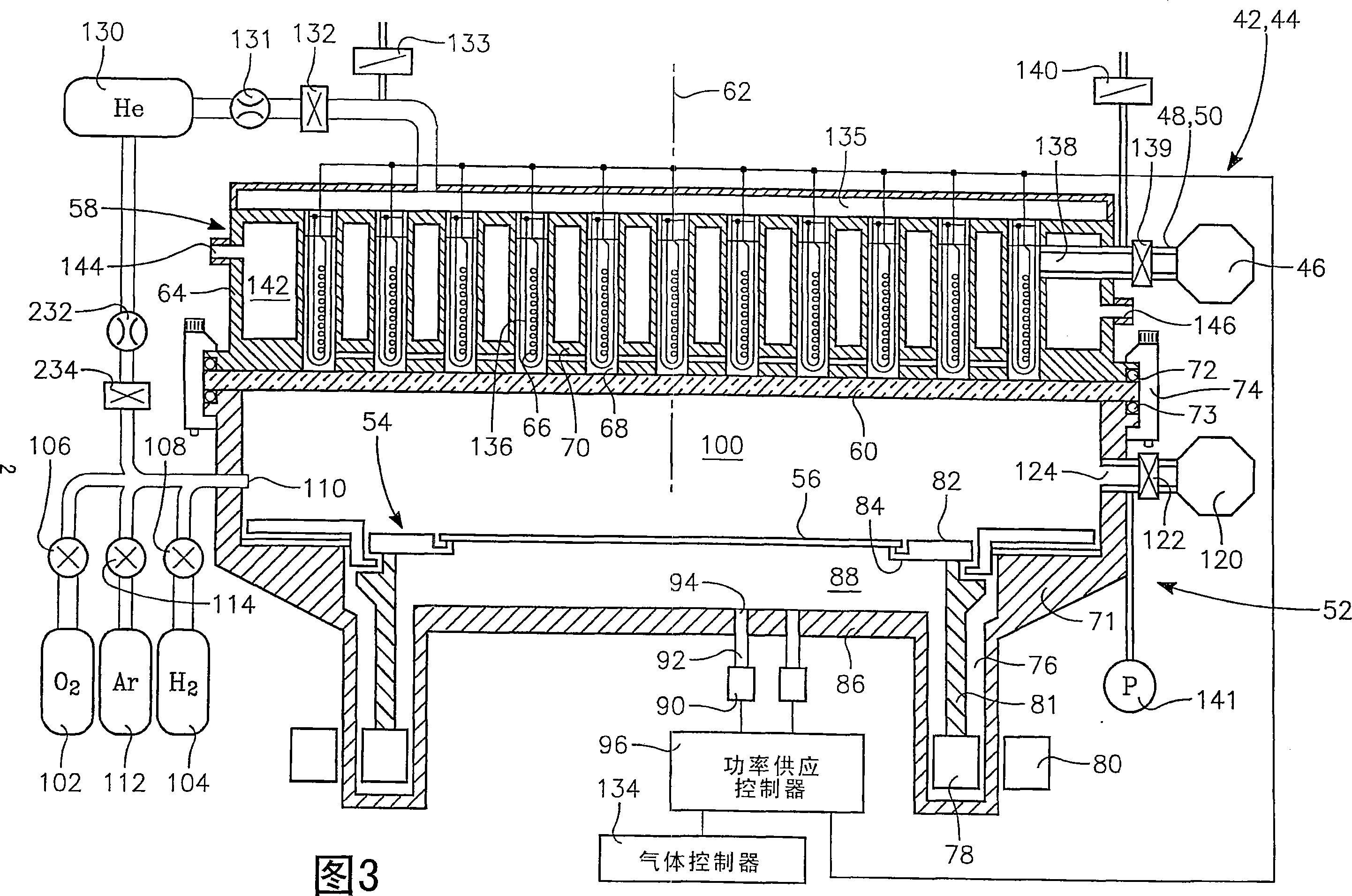

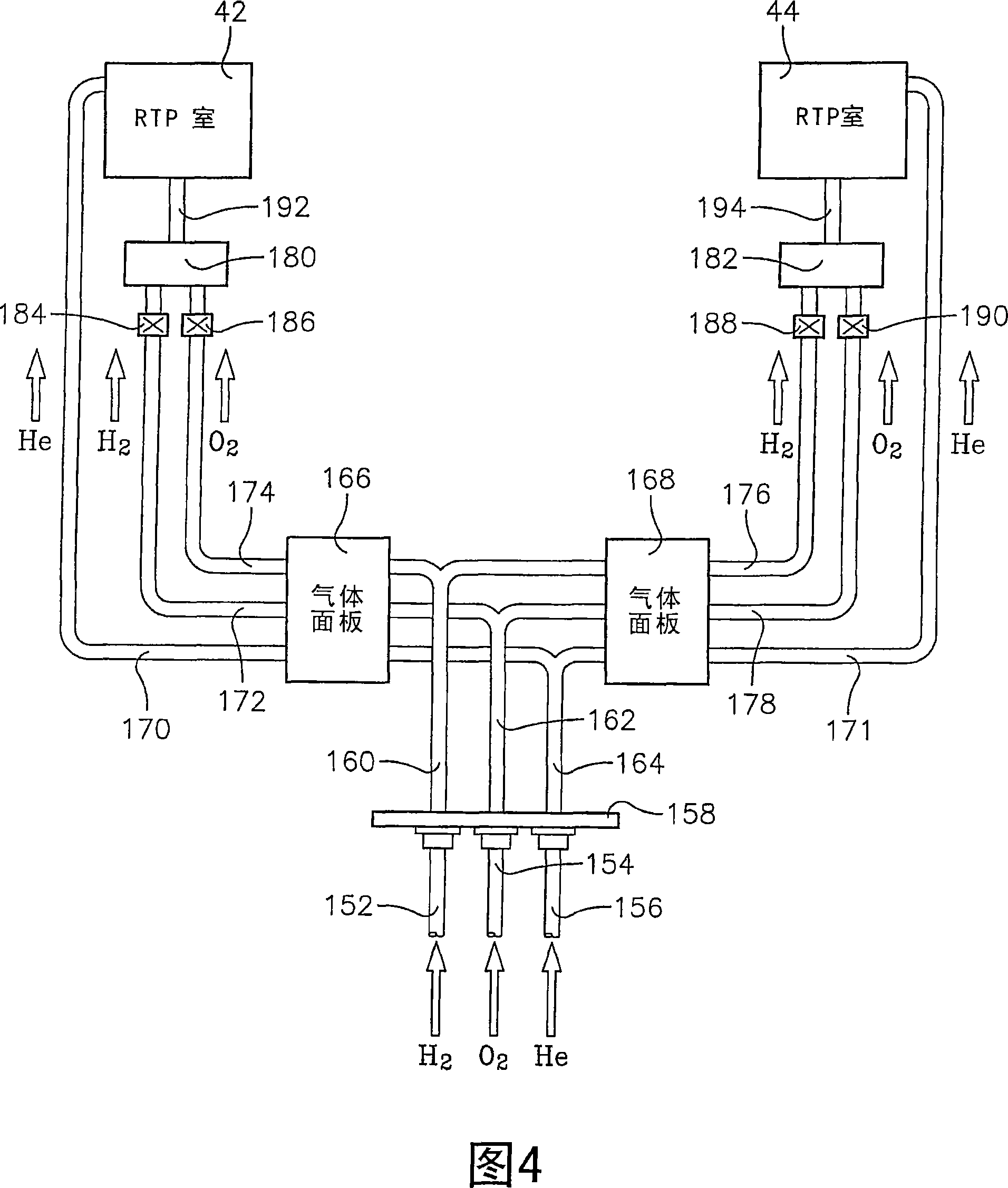

[0019] The general type of platform illustrated in FIG. 1 has a factory interface 26 but no load locks and can be modified into a multi-chamber system 40 illustrated in the orthographic view of FIG. 2 for mixed processing environments and With one or two rapid thermal processing (RTP) chambers 42, 44, the rapid thermal processing chambers 42, 44 can be vacuumed to lower pressures and allow the use of toxic gases. Furthermore, the system 40 includes a vacuum pump 46 for pumping the two RTP lampheads, supported on the frame 16 and connected to the RTP chambers 42 , 44 by discharge lines 48 , 50 . The rapid thermal processing chambers 42, 44 are examples of low pressure chambers capable of operating at internal processing pressures below 200 Torr. Chambers other than RTP chambers can be used in the present invention, but RTP is of immediate benefit. Low pressure is required during undesired purge of process gas from the chamber. The low pressure requires additional features in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com