Energy-saving method for electric dust removing system

A technology of electrostatic precipitator and electric field, applied in power supply technology, electrostatic separation and other directions, can solve problems such as inability to distribute power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

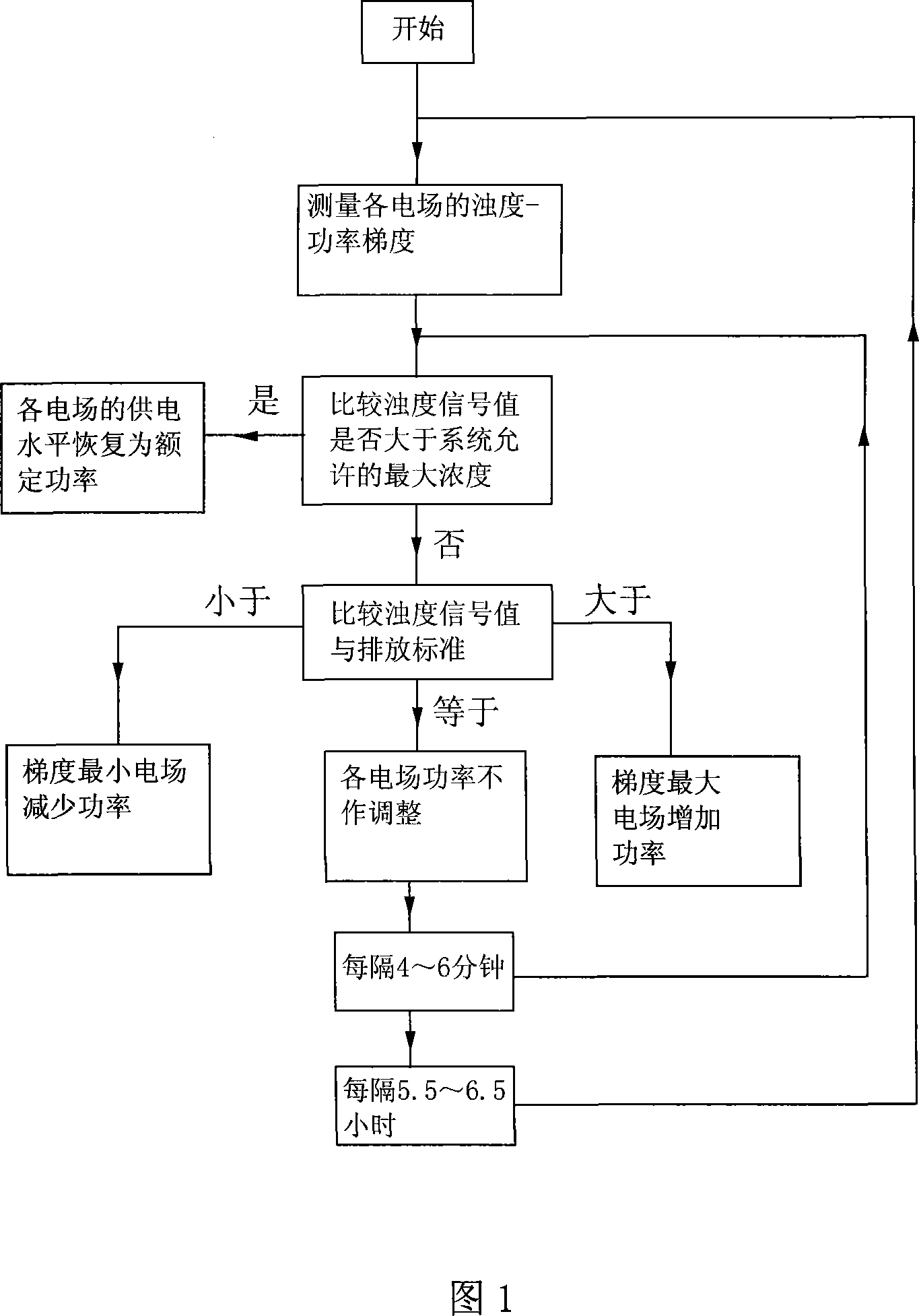

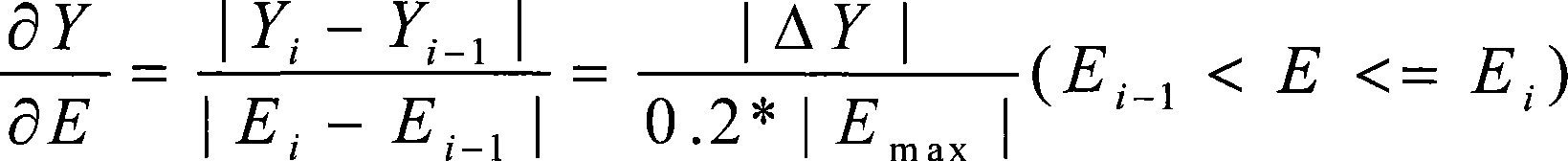

Method used

Image

Examples

Embodiment Construction

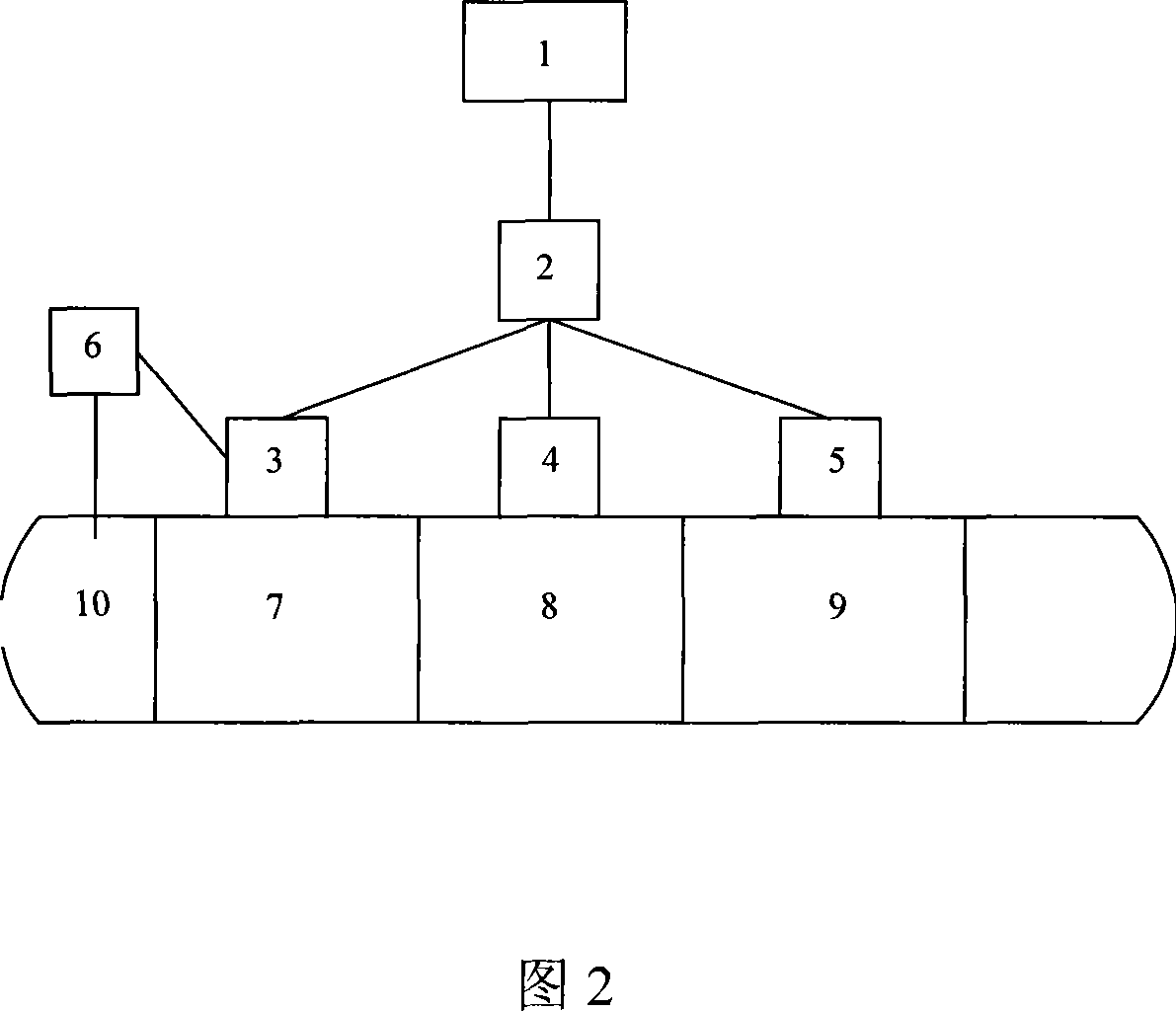

[0031] Figure 2 shows an electrostatic precipitator system, which has 3 electric fields, namely electric field I7, electric field II8 and electric field III9. The dust passes through the electric field I7, the electric field II8 and the electric field III9 and is discharged into the chimney 10, and a turbidity meter 6 is provided at the outlet of the chimney 10.

[0032] The electric field I7 is controlled by the controller I3, the electric field II8 is controlled by the controller II4, and the electric field III9 is controlled by the controller III5. One end of the switch 2 is connected to the host computer 1, and the other end of the switch 2 is respectively connected to the controller I3 and the controller. II4 is connected to controller III5. That is, the controller I3, the controller II4 and the controller III5 are respectively connected to the upper computer 1 through the switch 2. The turbidity meter 6 is responsible for detecting the flue gas concentration, and it is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com