Drilling machine

A drilling machine and workbench technology, which is applied to the parts of boring machine/drilling machine, portable drilling machine, drilling/drilling equipment, etc., can solve the problems of non-adjustable and difficult-to-process workpieces, and achieve large working space, good rigidity, and structure novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

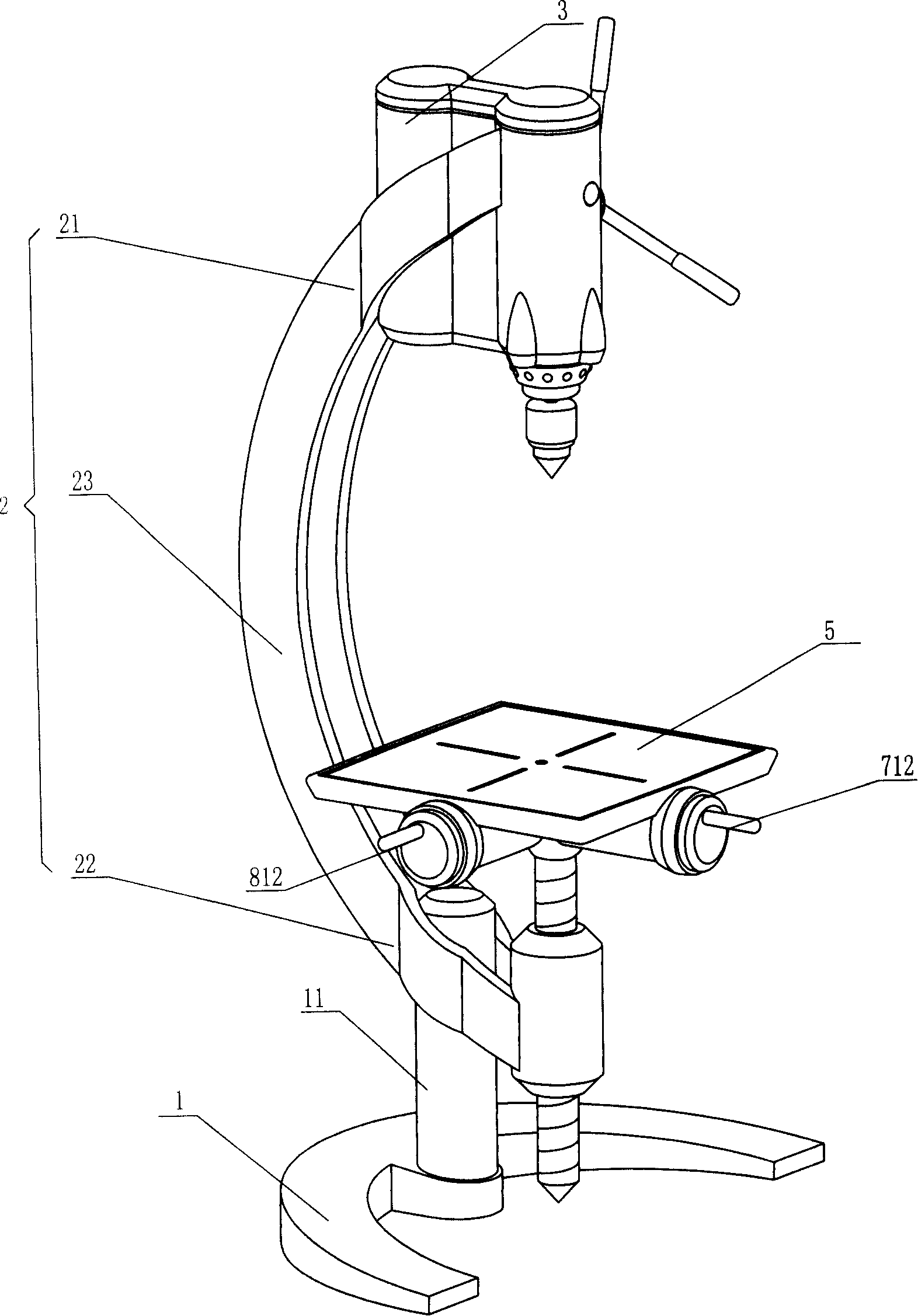

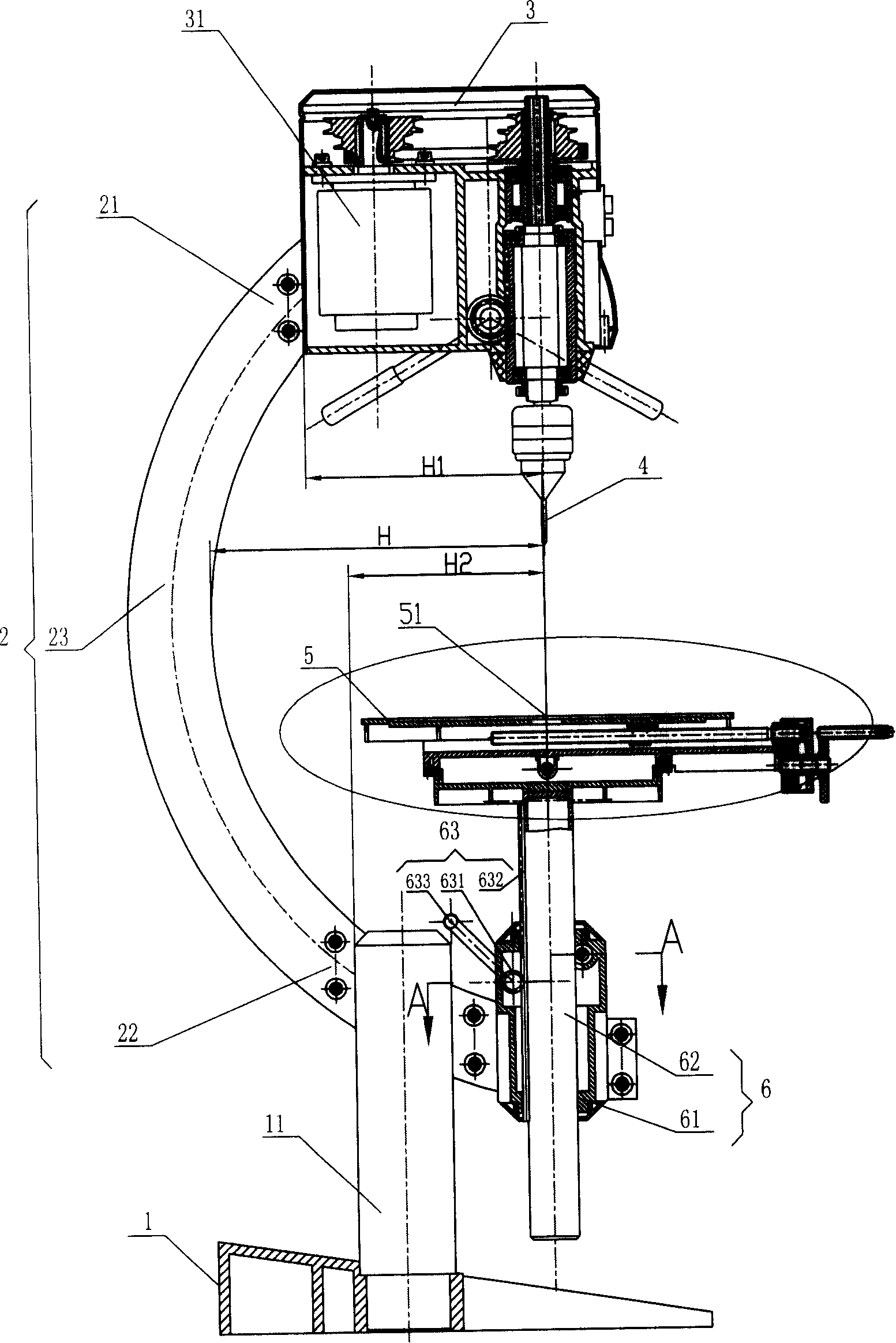

[0029] Such as figure 1 As shown, a drilling machine includes a base 1 , a bracket 2 matched with the base 1 , a headstock 3 matched with the bracket 2 , and a workbench 5 roughly arranged in the middle of the bracket 2 in the vertical direction. Wherein the base 1 is a "C"-shaped structure, and of course it can also be in other shapes; the bracket 2 includes a first end 21 matched with the headstock 3, a second end 22 matched with the column 11 of the base 1, and a first end 22 connected to the first The connection portion 23 between the end 21 and the first end 22. The connecting portion 23 is a traditional straight column, but a non-linear special-shaped structure. In this embodiment, the connecting portion 23 is a “C”-shaped structure.

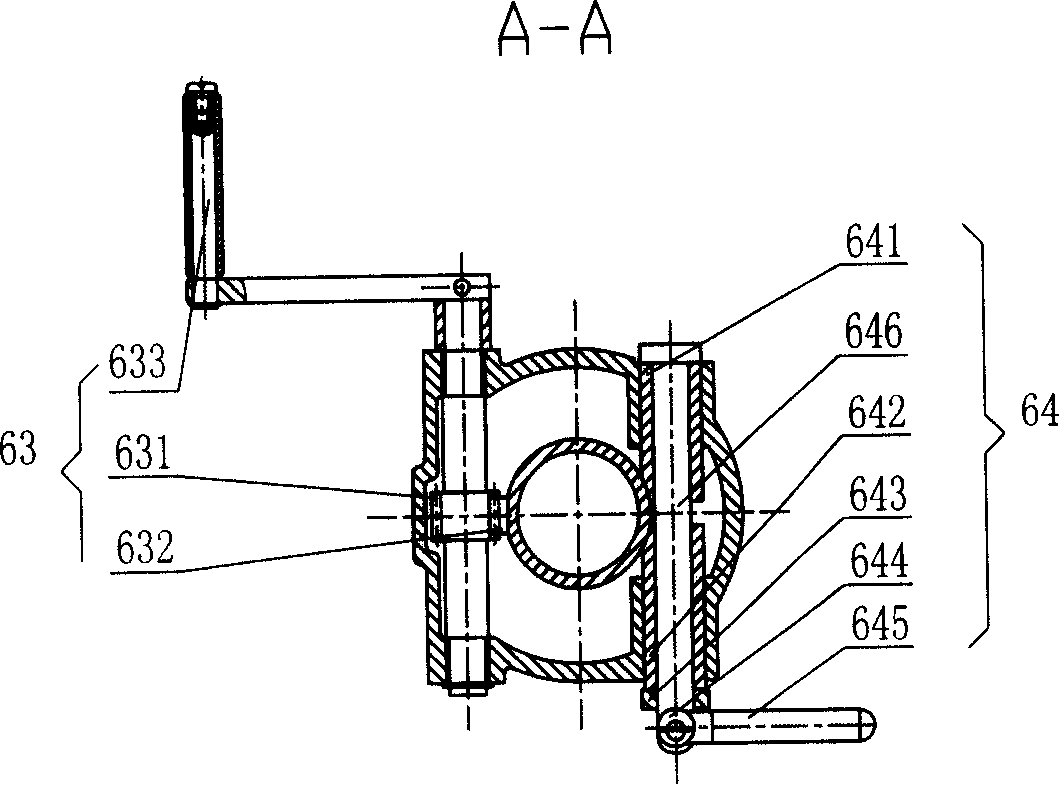

[0030] Such as figure 2 As shown, the horizontal distance H from any point of the connecting portion 23 to the vertical centerline 51 of the workbench 5 is greater than the horizontal distances H1 and H2 from any point of the first end ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap