Injection molding control method

一种注射模制、控制方法的技术,应用在电气程序控制、顺序/逻辑控制器中的程序控制、塑料回收等方向,能够解决很难获得合格产品等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

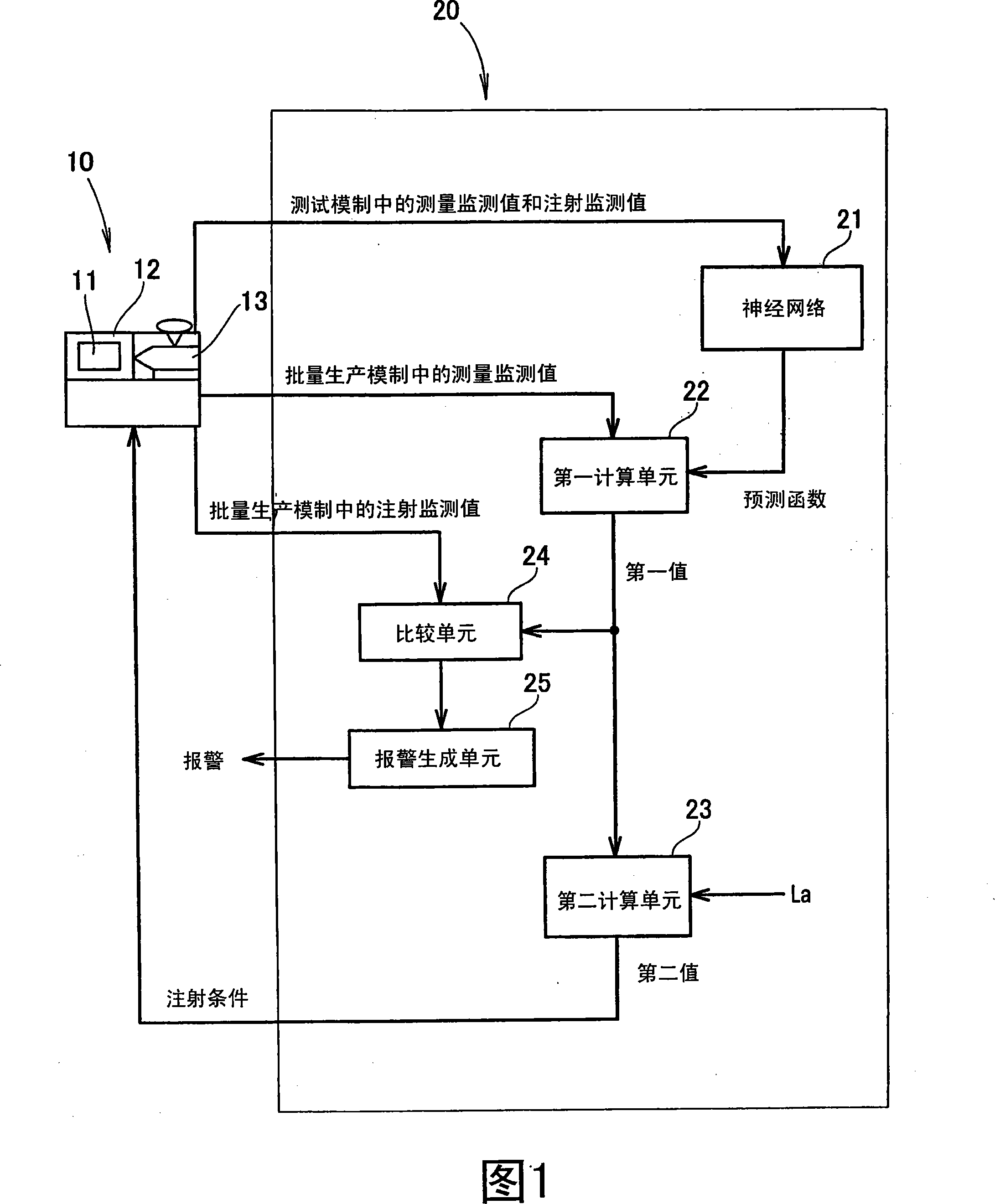

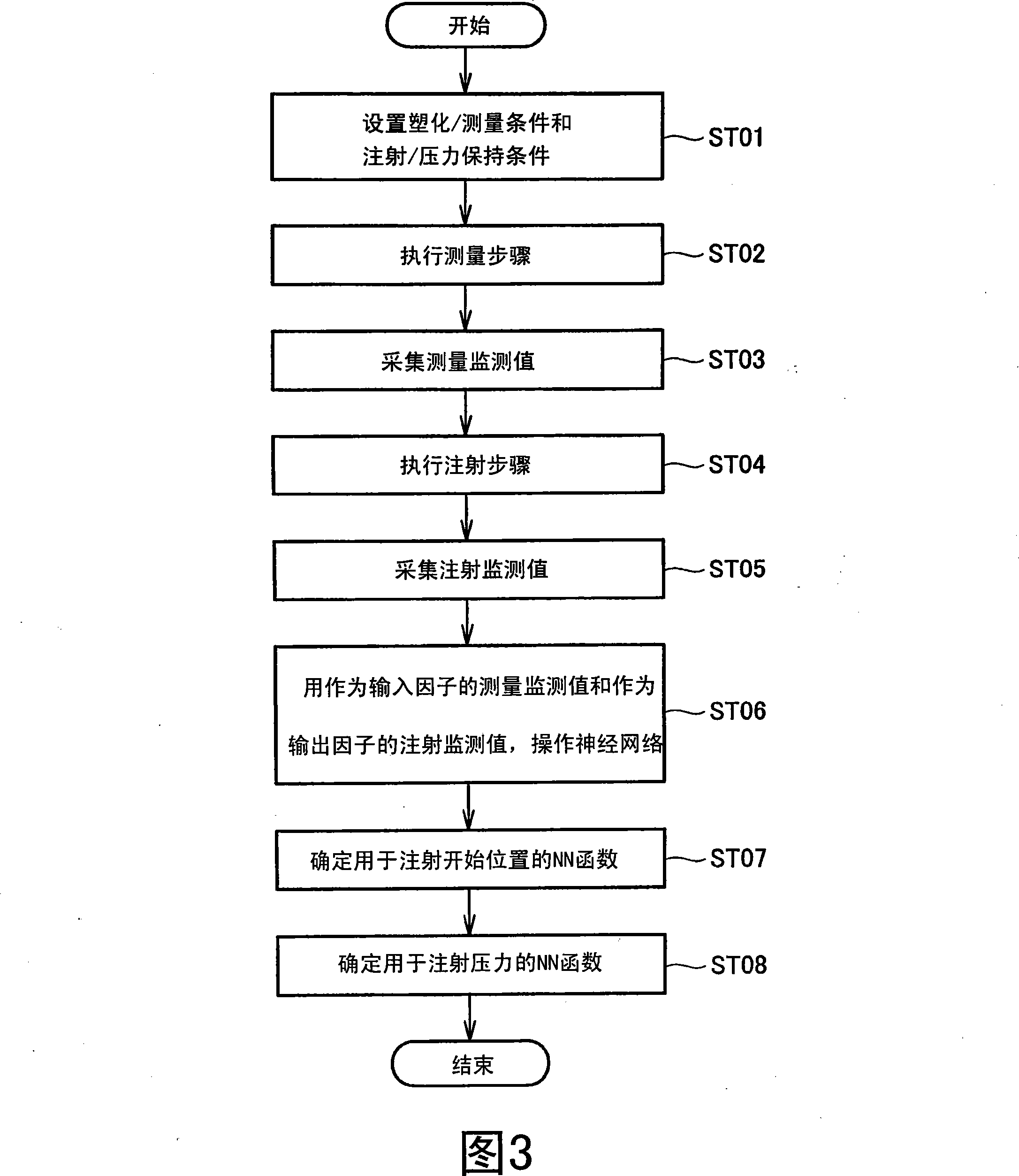

[0043] As shown in FIG. 1 , the injection molding machine 10 is basically composed of a clamping device 12 for clamping a die 11 and an injection device 13 for injecting resin into the die 11 . The injection molding machine 10 is equipped with a control device 20 including a neural network.

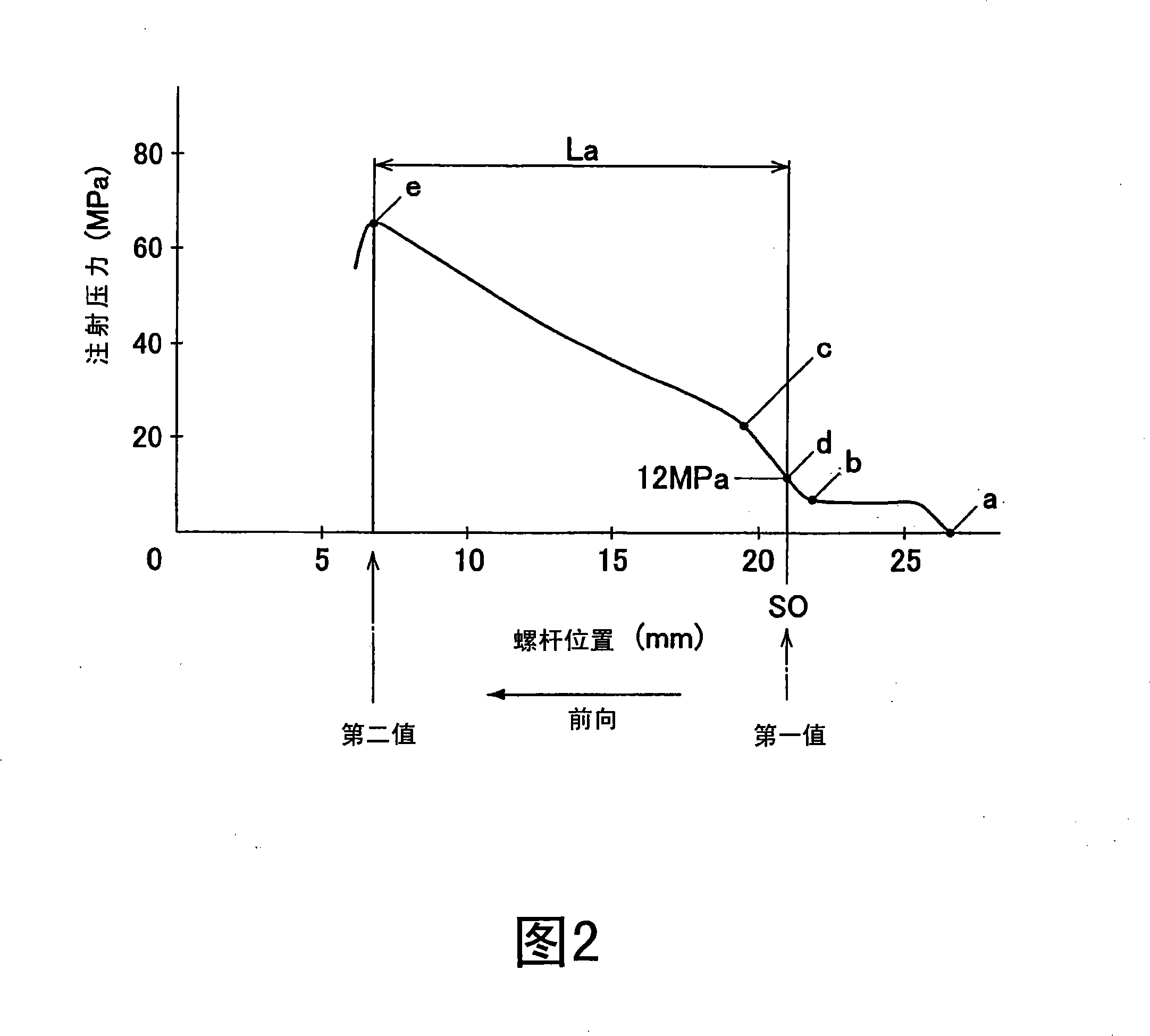

[0044] The control device 20 includes a neural network 21 for combining the measured monitoring values and the injection monitoring values of the test molding performed by the injection molding machine 10 and generating a prediction function; The prediction function, and the measurement monitoring value of the mass production molding performed by the injection molding machine 10, to calculate the first value; the second calculation unit 23 is used to calculate the corresponding value according to the first value calculated by the first calculation unit 22 The second value of the injection condition; the comparison unit 24 is used to compare the first value and the injection monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com