Method and device for preprocessing bobbin so as to compound-wound at an automatic cross-wound bobbin winder

A technology for pre-treating bobbins, applied in the field of pre-treating bobbins for rewinding and installation on automatic cross-winding winders, to avoid severe distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

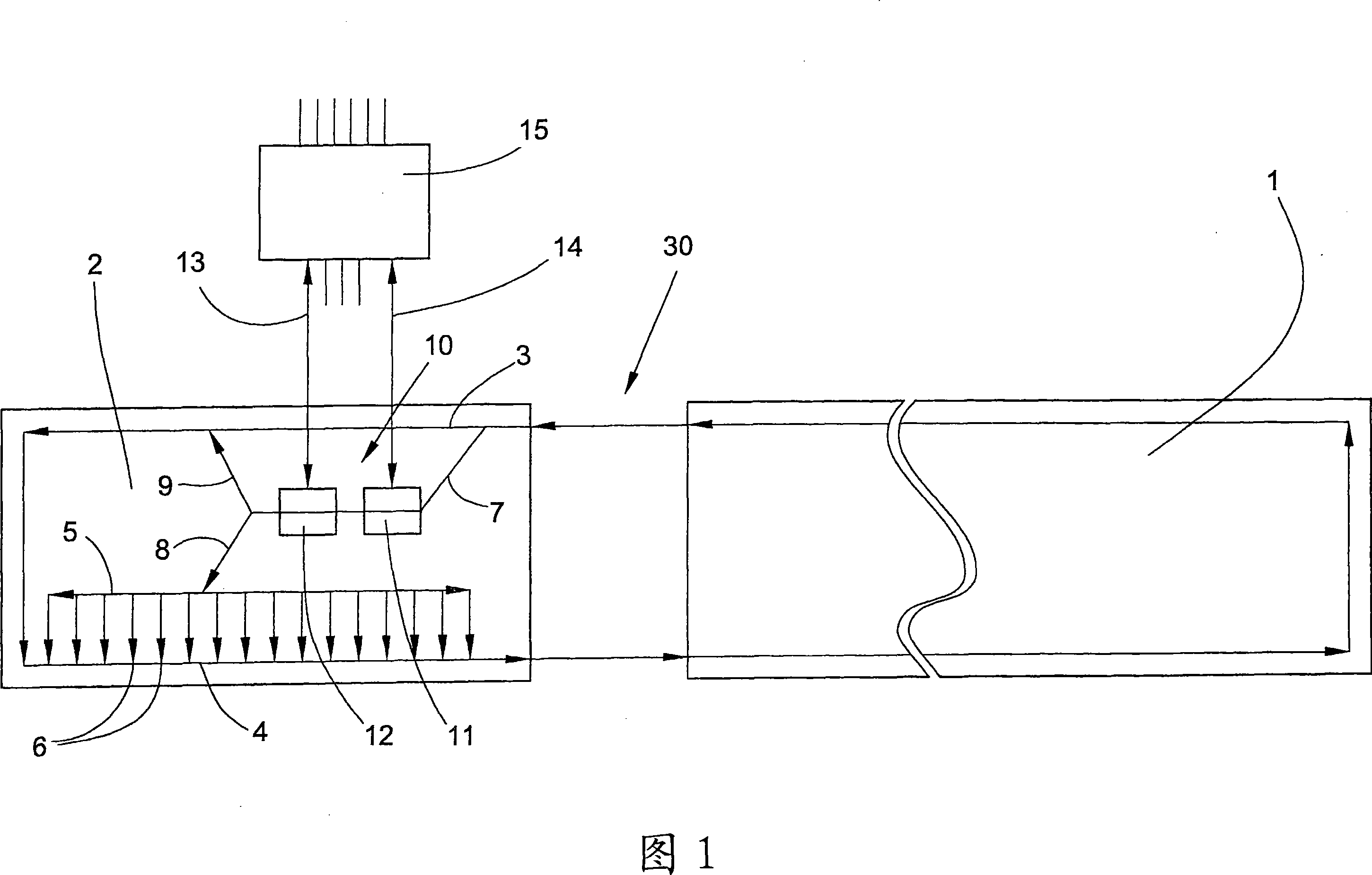

[0026] Figure 1 shows the combination of a ring spinning machine and an automatic cross-winding winder in a schematic top view. Here, the ring spinning machine is marked 1, while the automatic cross-winding machine is marked 2. As is known per se and is therefore only indicated schematically with arrows, the two textile machines are connected via a bobbin / empty tube conveyor system 30 . The conveying sections of the bobbin / empty bobbin conveying system 30, arranged in the area of the automatic cross-winding winder, are the bobbin conveying section 3, the bobbin return section 4, the reversibly driven storage section 5 and the delivery to the winding station The lateral conveying section 6. Furthermore, at least one so-called pretreatment section 7 is connected to the bobbin delivery section 3 , the ends of which are connected via branches 8 and 9 to the storage section 5 or again to the bobbin delivery section 3 .

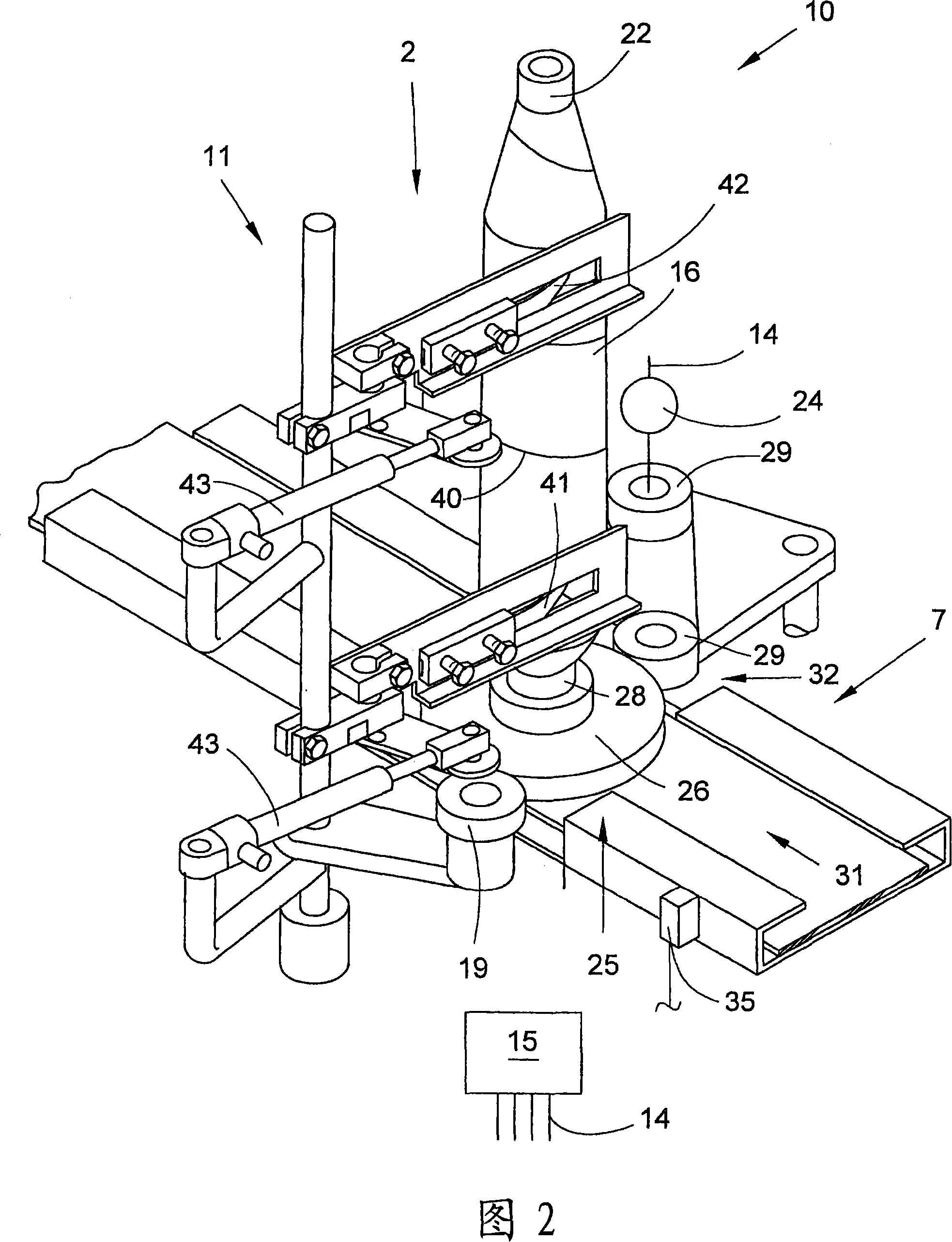

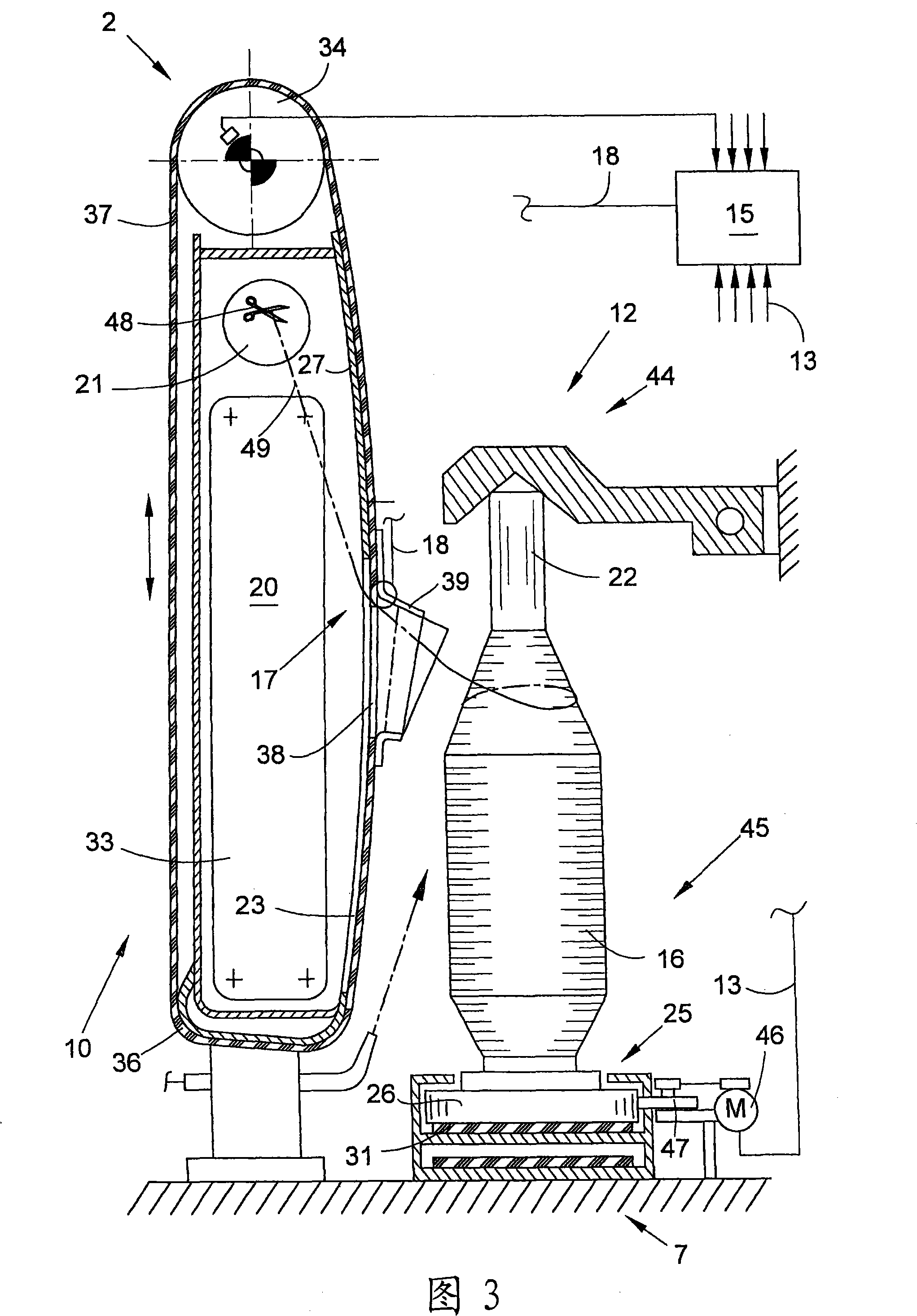

[0027] In the region of the pretreatment section 7, a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com