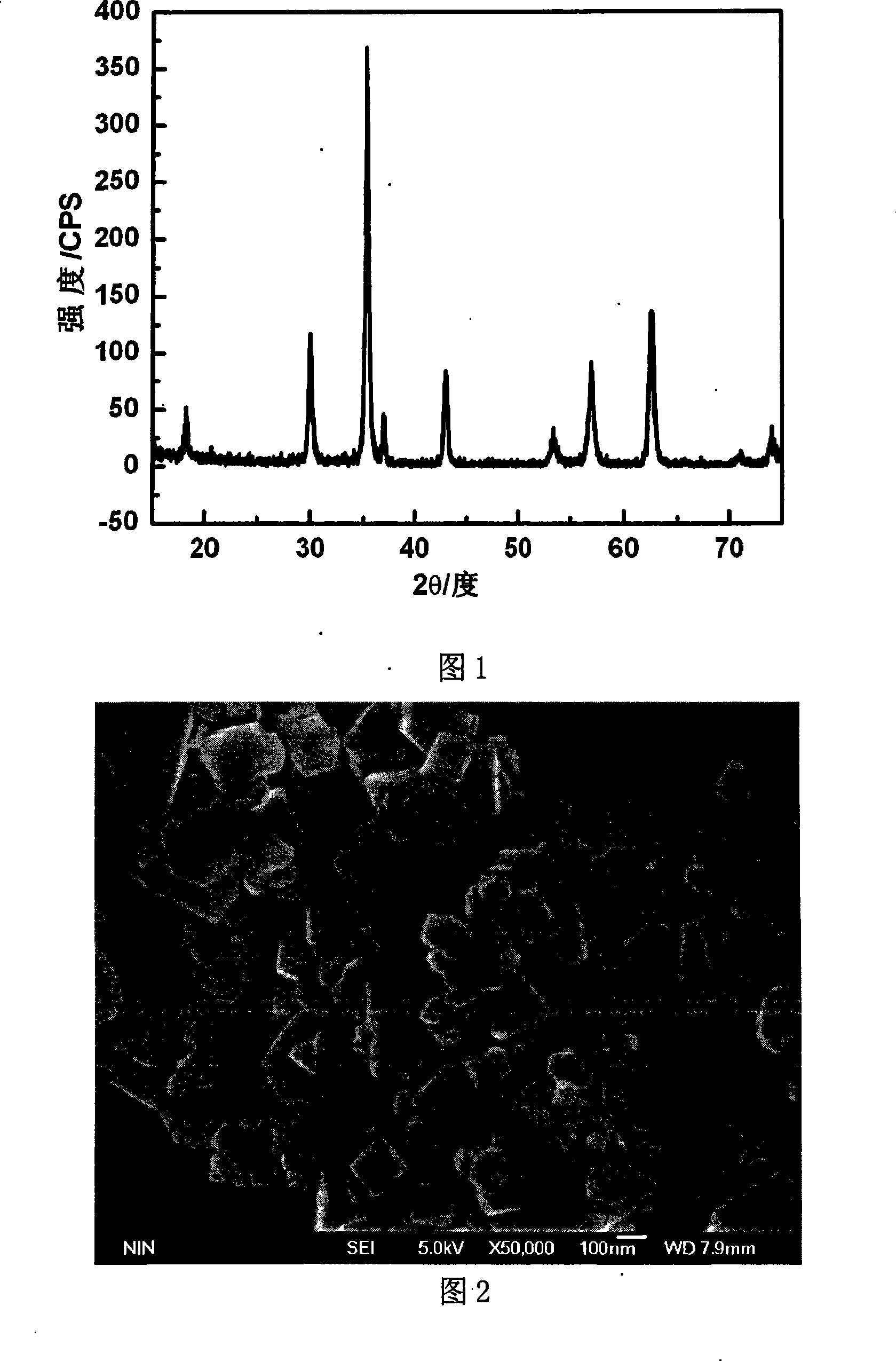

Method for preparing cobalt ferrite super fine powder at low temperature

A technology of cobalt ferrite and ultrafine powder, applied in the field of material science, can solve the problems of strict equipment requirements and high energy consumption, and achieve the effects of good grain development, low preparation cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

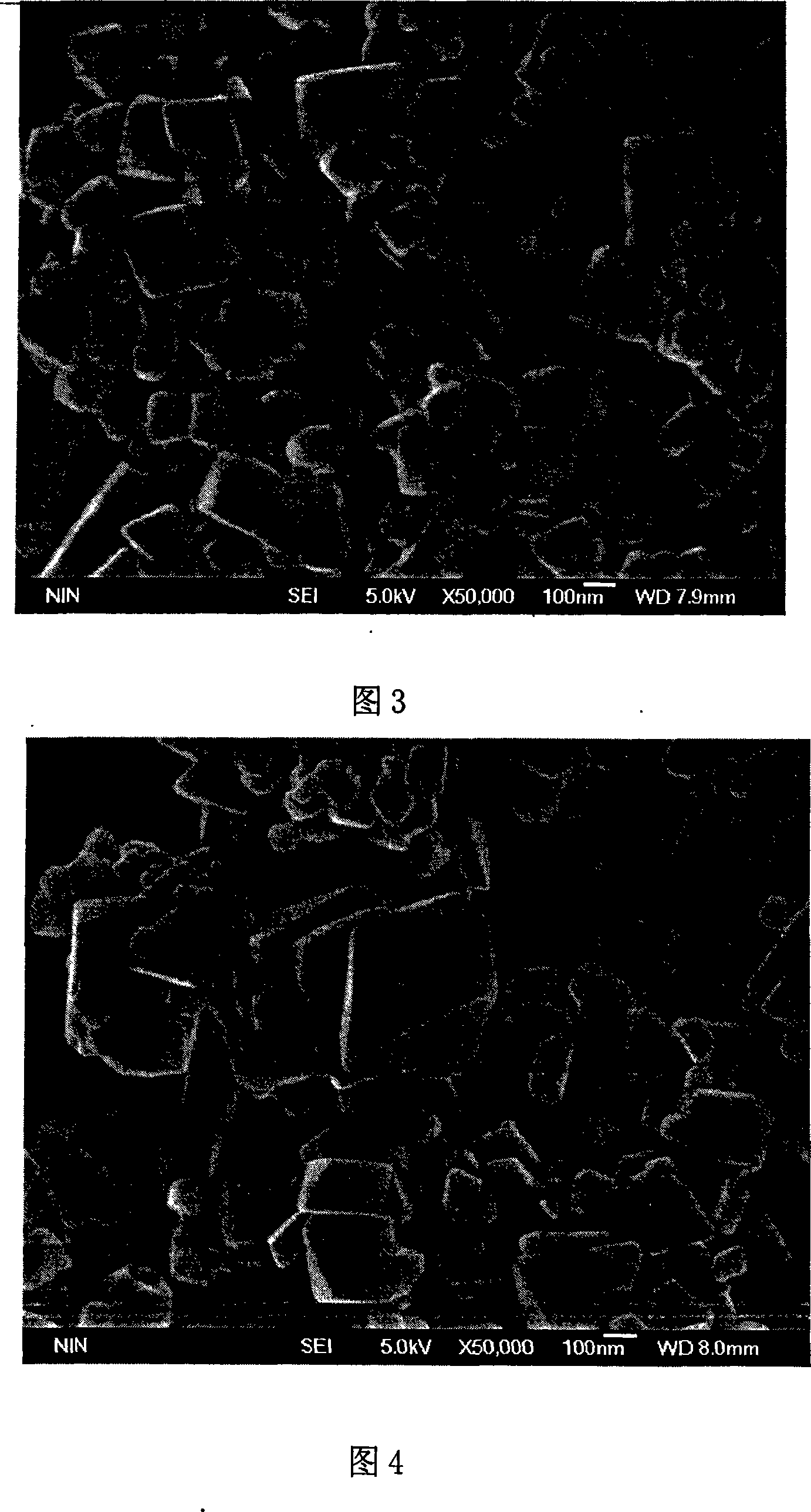

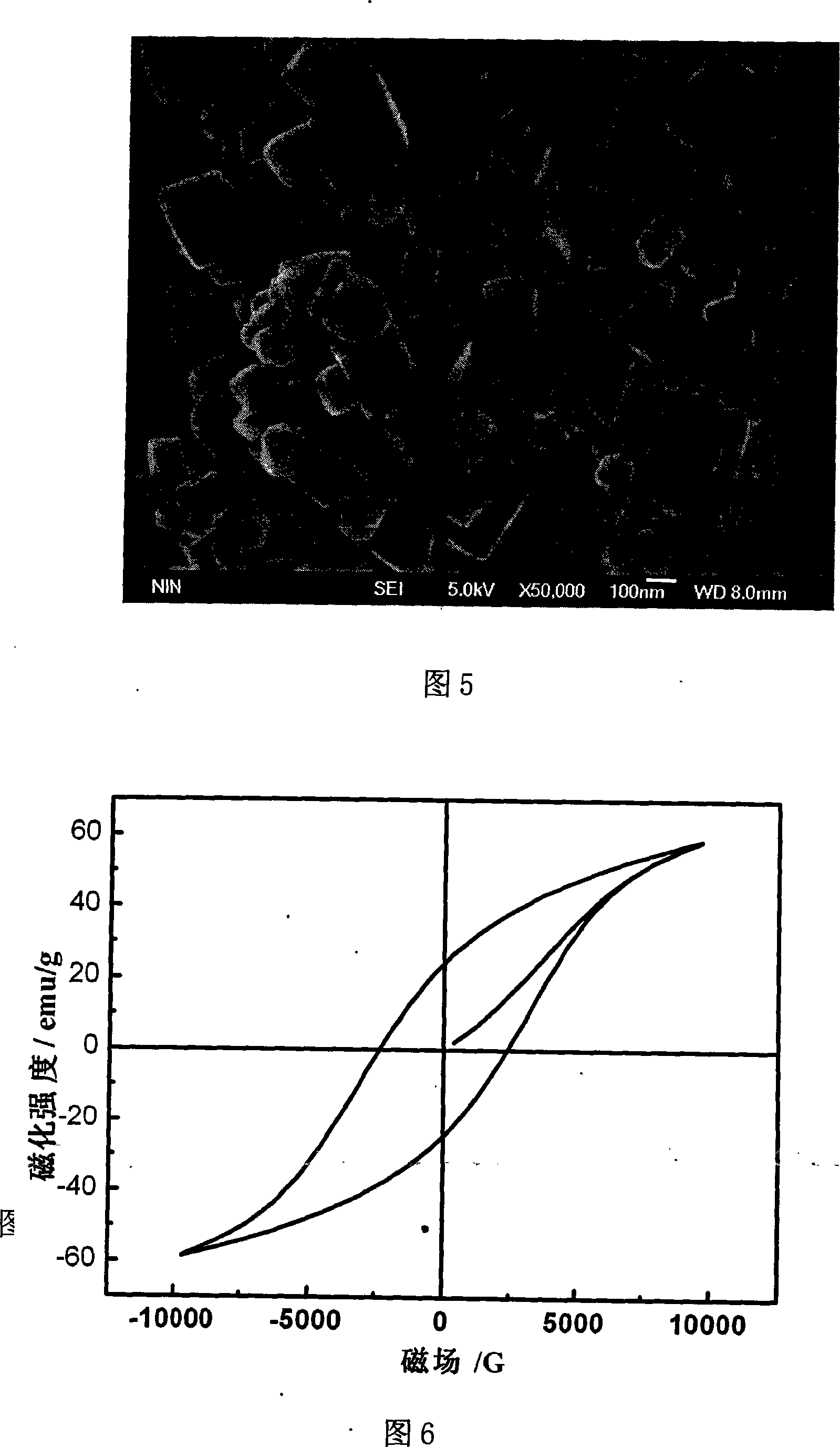

[0013] Embodiment 1, at first, by CoFe 2 o 4 The general chemical formula will be Co 3 o 4 and Fe 2 o 3 The powders are mixed, and then 200% KOH of the mass of the mixed powder is added to the mixed powder and mixed uniformly to obtain a mixture; secondly, the mixture is put into a container and calcined at 750° C. for 1 hour; finally, the calcined product is finely ground, Washing, filtering to remove salt to obtain superfine cobalt ferrite powder.

Embodiment 2

[0014] Embodiment 2, at first, by CoFe 2 o 4 The general chemical formula will be Co 3 o 4 and Fe 2 o 3 The powders are mixed, and then 100% NaOH of the mixed powder mass is added to the mixed powder and mixed uniformly to obtain a mixture; secondly, the mixture is put into a container and calcined at 700° C. for 2 hours; finally, the calcined product is finely ground, Washing, filtering to remove salt to obtain superfine cobalt ferrite powder.

Embodiment 3

[0015] Embodiment 3, at first, by CoFe 2 o 4 The general chemical formula will be Co 3 o 4 and Fe 2 o 3 The powders are mixed, and then 150% Li of the mass of the mixed powder is added to the mixed powder 2 SO 4 and Na 2 SO 4Mix evenly to obtain a mixture; secondly, put the mixture into a container, and calcinate at 800° C. for 1 hour; finally, grind the calcined product finely, wash, and filter to remove salt to obtain superfine cobalt ferrite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com