Moorage rope twisting elimination coiling assembly method

An assembly method and a mooring cable technology, which are applied in the directions of transportation and packaging, ships, special-purpose ships, etc., can solve the problems of easy torsion, self-entanglement, twisting and breaking of the retaining cable and the buoy joint, and achieve a simple structure combination. , release the effect of high reliability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

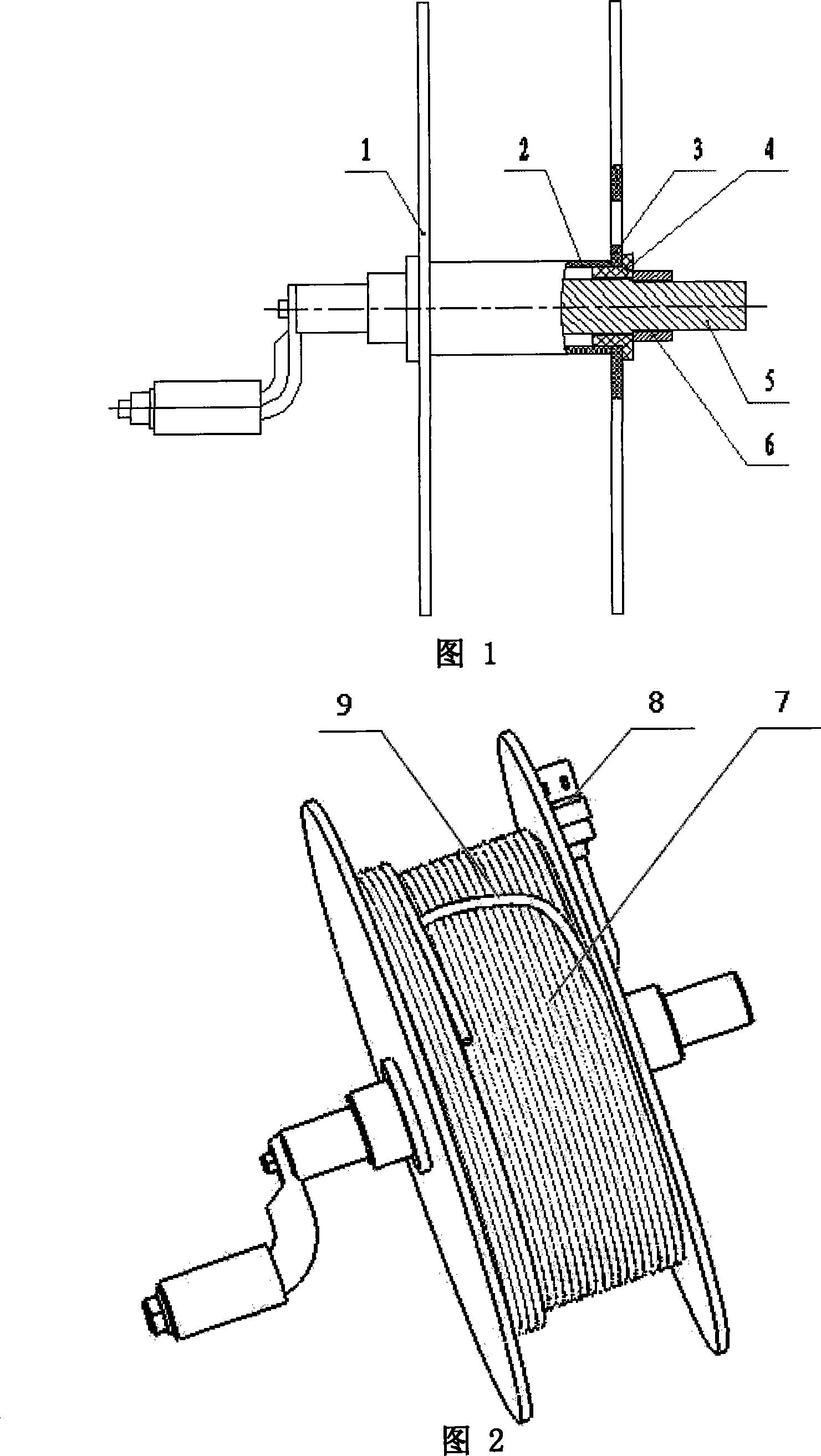

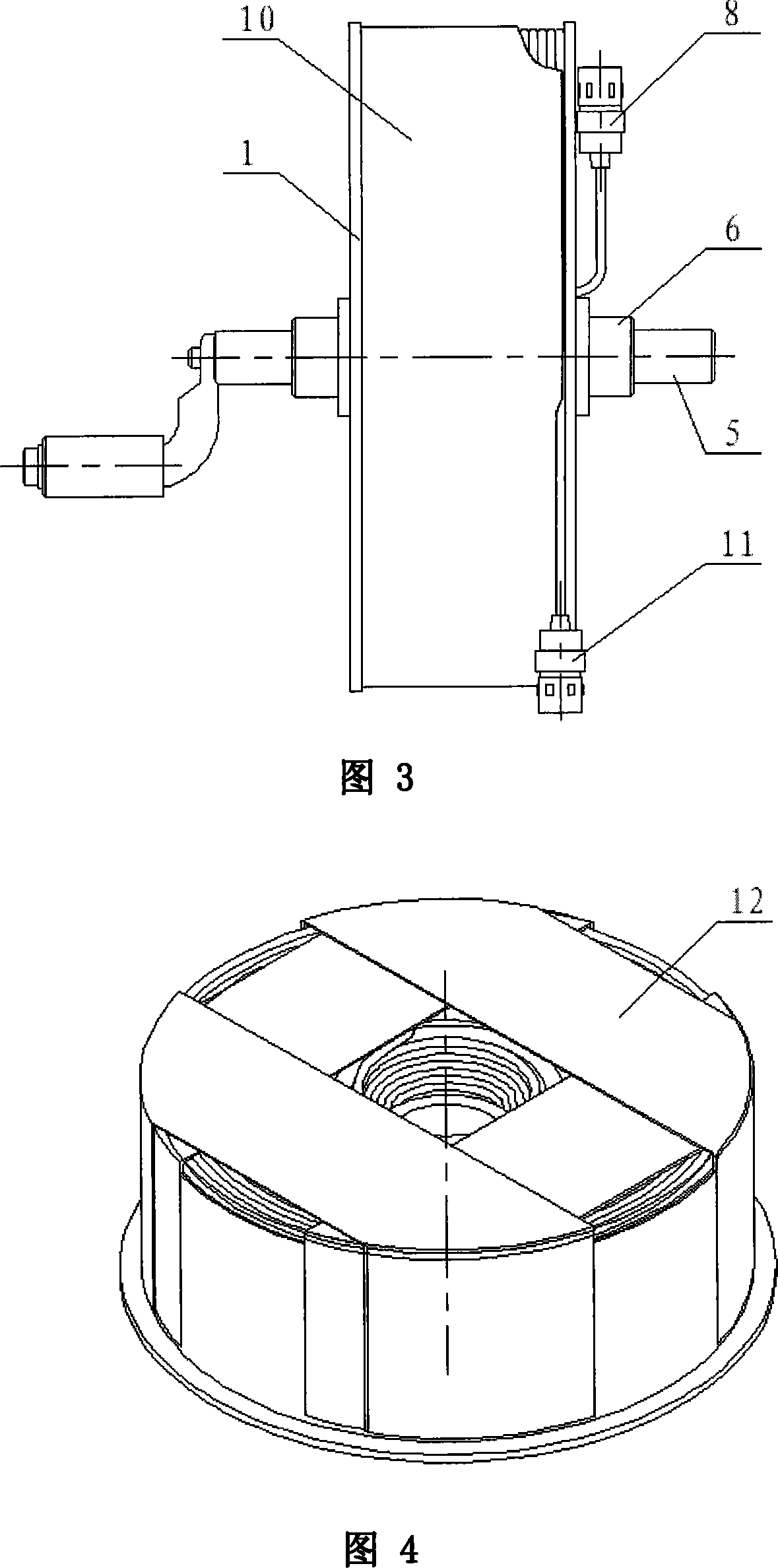

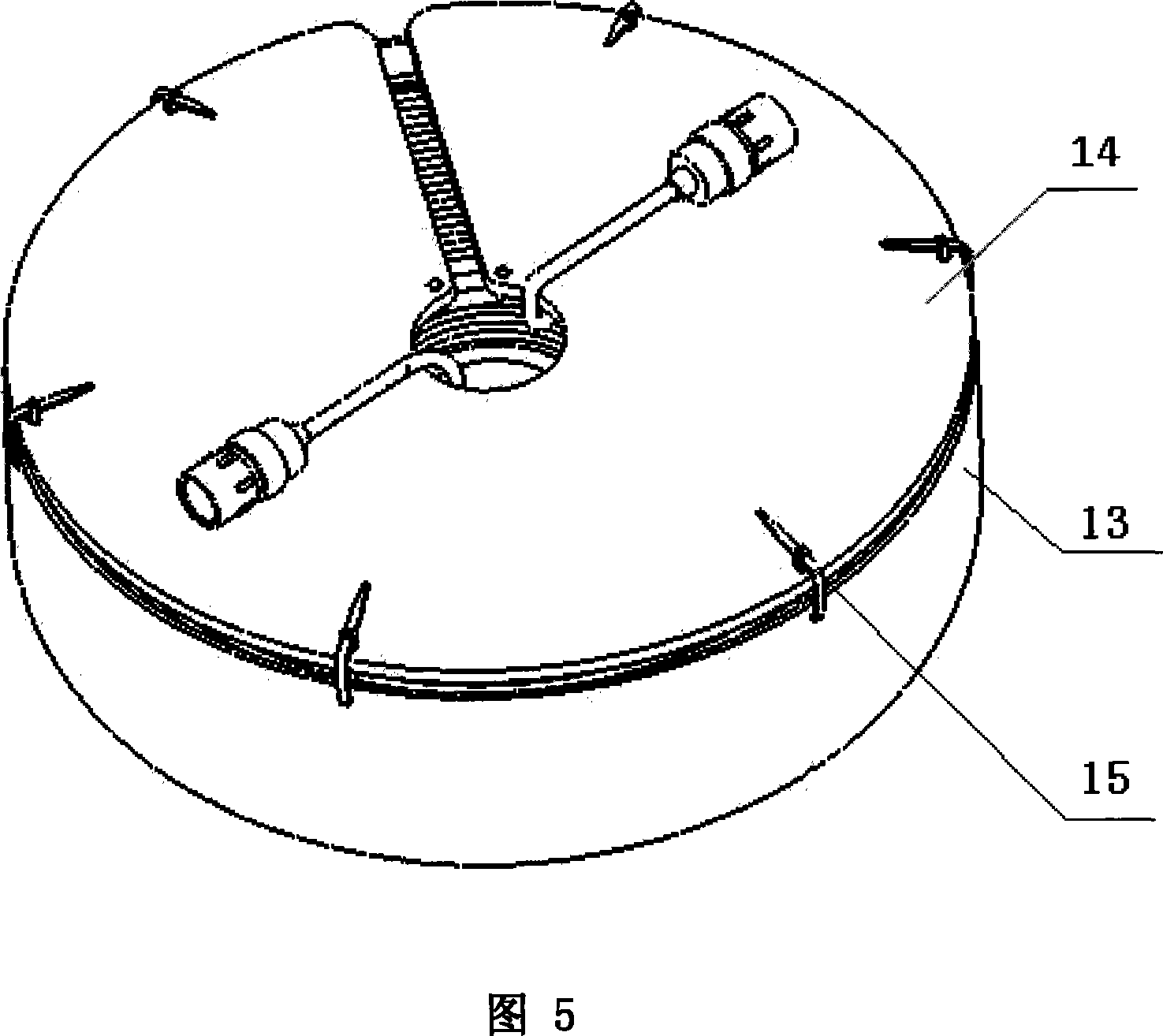

[0020] A method for assembling a mooring cable to eliminate torsion coils, comprising the following steps:

[0021] a. Coiled mooring line:

[0022] Determine the length of the mooring rope in advance according to the requirements of use, and place it freely on an auxiliary turntable, and then place the auxiliary turntable and the winding tool together on the operating frame. 8 From the left splint 1 to the right splint 2, pass through the right splint 2 with holes from the inside to the outside, fix it on the outer side of the right splint 2, start to coil on the sleeve 2, and coil the positive and negative alternately and tightly layer by layer , if the first layer is tightly coiled clockwise from the side of the left splint 1, when the coil reaches the side of the right splint 2, then fold back to the side of the left splint 1, and start to press the folded mooring cable 9 and the mooring cable of the first layer, carry out the tight coiling of the second layer in the oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com