Technique for producing artificial diamond

A technique for making craft, man-made diamonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

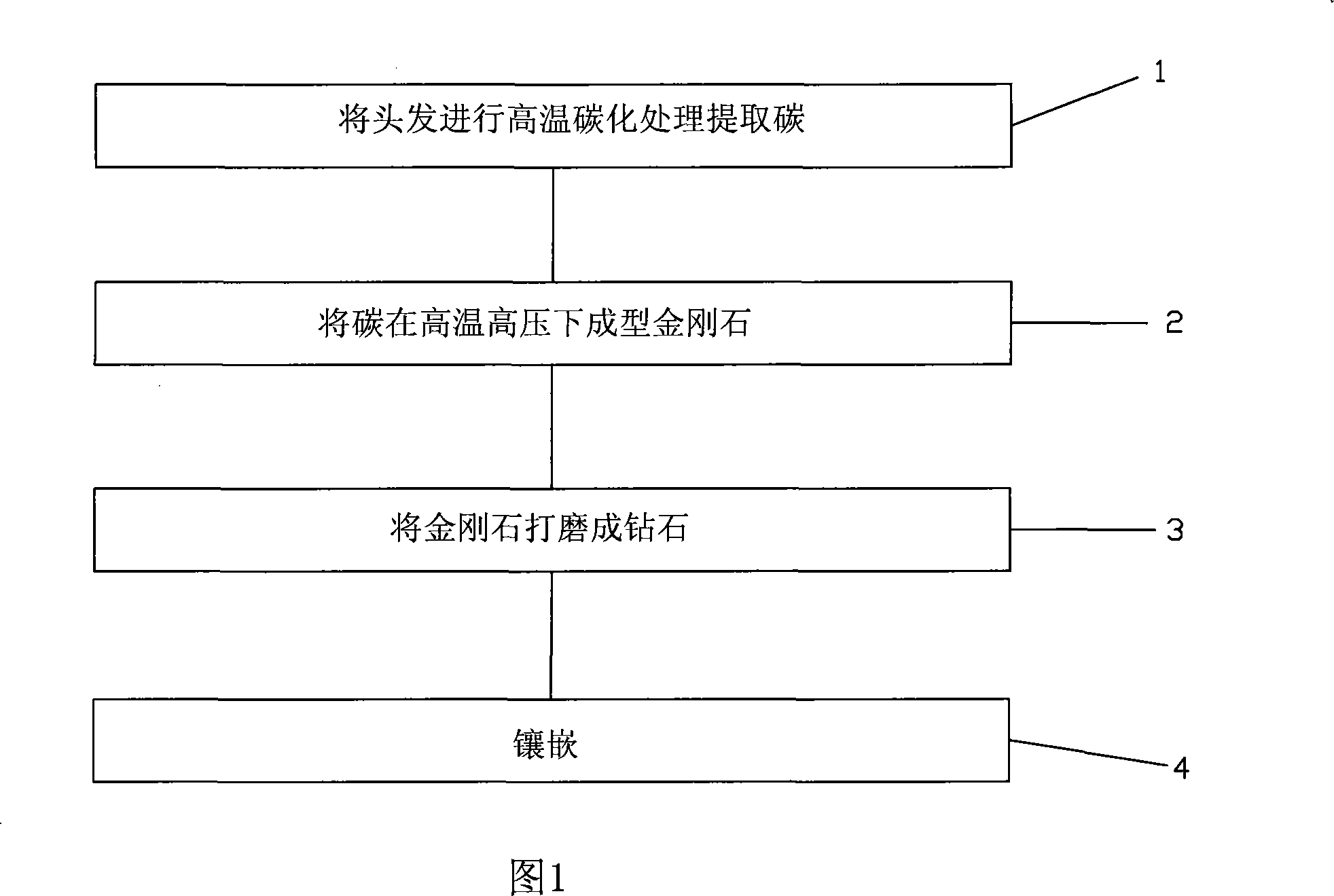

[0016] Referring to Fig. 1, it is a flowchart of the manufacturing process of the artificial diamond of the present invention. The method includes the following steps:

[0017] Step 1: Carry out high-temperature carbonization treatment of hair to extract carbon; the composition of natural diamonds is carbon, and carbon also accounts for a large proportion in the composition of hair. Starting from the common point of the two, first crack the organic matter of hair and extract it from it. carbon element. Each hair can extract about 0.1-1.0 mg of carbon. The temperature is above 2000°C.

[0018] Step 2: Shape carbon into diamond under high temperature and high pressure; vacuum-dry the carbon extracted in step 1 and put it into the six-sided top machine. The six-sided top machine is a special equipment for artificially synthesizing superhard materials such as diamond. Carbon is compressed and crystallized under high temperature and high pressure similar to the simulated environ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com