Dust separator

A separator, dust mist technology, applied in separation methods, dispersed particle separation, use of liquid separation agents, etc., can solve problems such as failure to achieve separation effect, single shape, small backflow and vortex, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

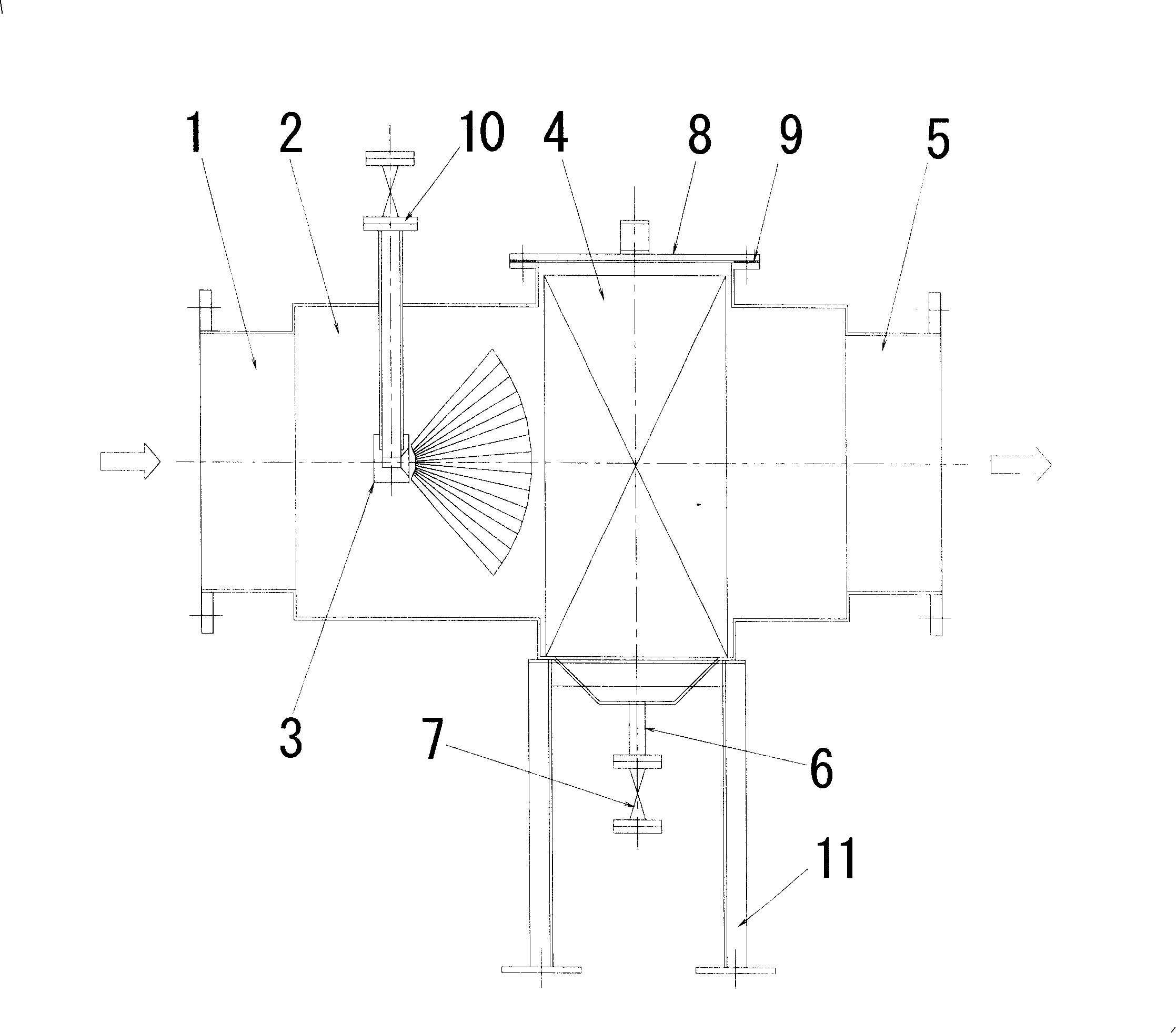

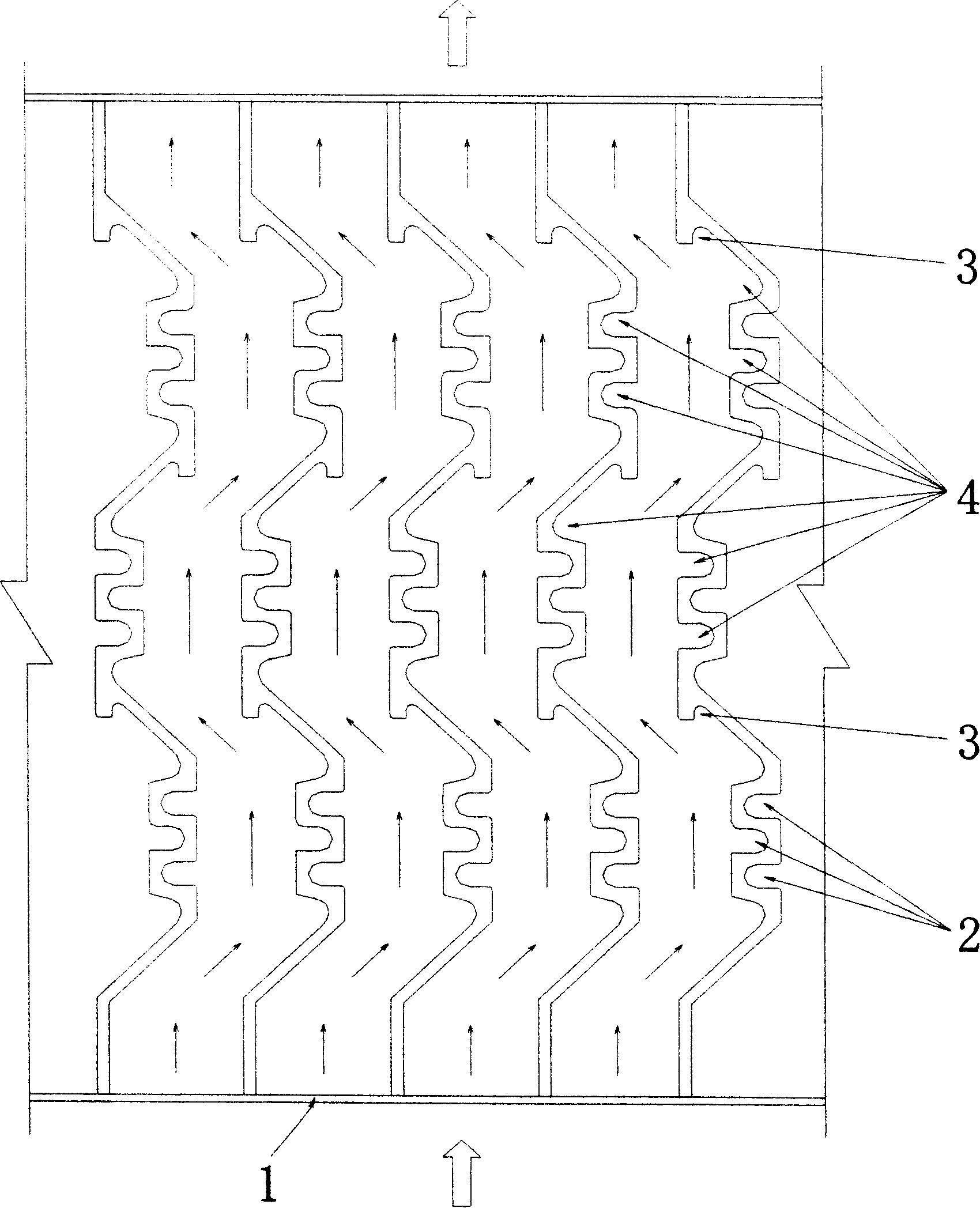

[0012] Below in conjunction with embodiment and accompanying drawing 1, accompanying drawing 2 further illustrate the patent of the present invention.

[0013] In the embodiment shown in Figure 1, when the waste gas is forced into the housing 1, it flows into the waste gas inlet pipe 2, passes through the water inlet control valve 10 and connects the water inlet pipe and the nozzle to form a sprinkler device 3, which consists of The umbrella-shaped water mist sprayed by the sprinkler device 3 is aimed at the inlet position of the dust and mist separation device 4, and pre-treats the fine dust particles contained in the exhaust gas, so that the mist-like water is fused with the fine dust particles contained in the exhaust gas , to exert the ability of water to absorb dust particles, so that the moisture, particle size and weight of dust particles contained in the exhaust gas increase to form water droplets, which is convenient for effective separation. The waste gas after spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com