Card producing system with pneumatic pressure cylinder

A pneumatic pressurization and card making technology, which is applied in the direction of mechanical processing/deformation, cardboard items, etc., can solve the problems of slow output action speed, high noise of the oil pressure system, and affecting the card making speed, etc., and achieves easy output adjustment and action speed Fast and save power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

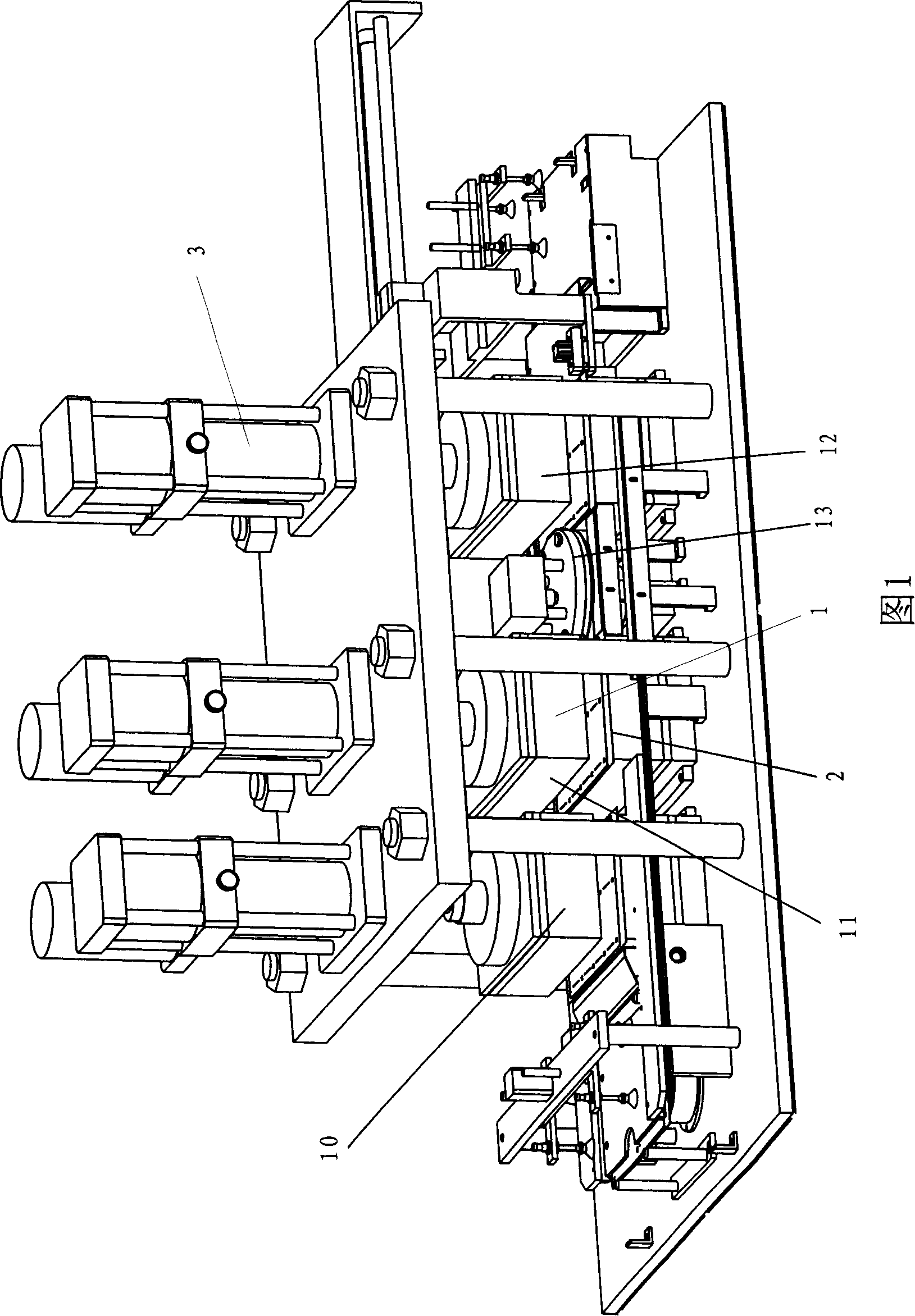

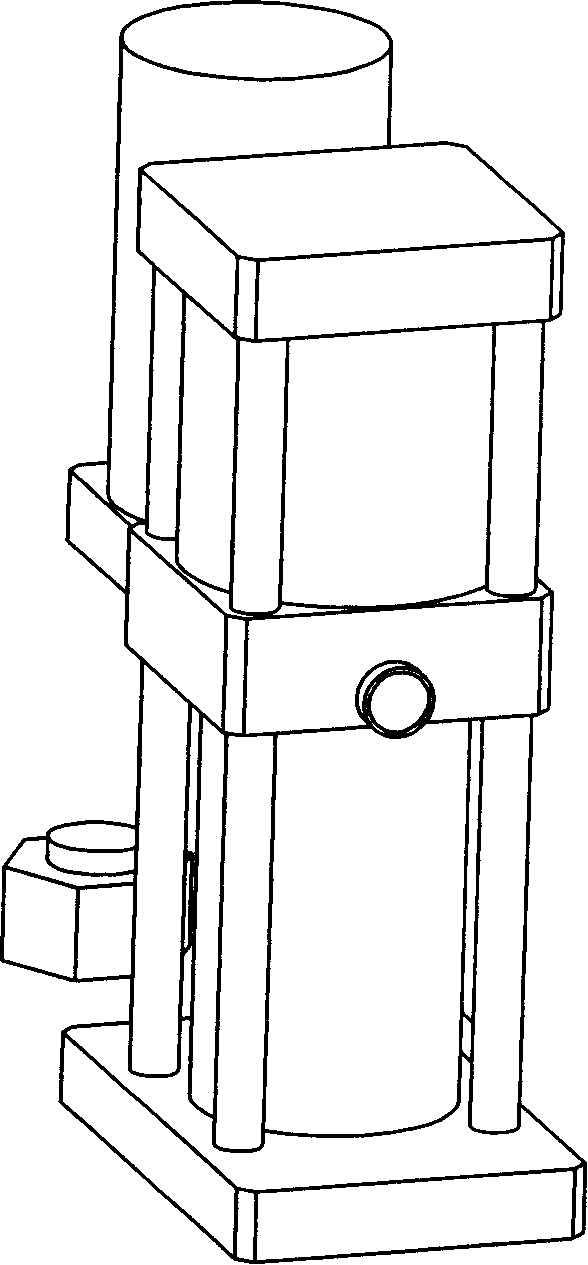

[0017] The card making system of the present invention includes pre-positioning equipment, flat pressing equipment and punching equipment. As shown in FIG. 1 , it is a schematic structural view of the flat pressing device of the present invention. The flat pressing equipment includes a preheating flat pressing unit 10 , a hot flat pressing unit 11 and a cold pressing unit 12 . Between the hot flat pressing unit 11 and the cold pressing unit 12, a rotary feeding unit 13 is provided, and the two ends of the rotating feeding unit 13 are provided with double-layer laminated films, which extend into the hot flat pressing unit 10 and the cold pressing unit 12 respectively. middle. The work of the preheating flat pressing unit 10 , the hot flat pressing unit 11 and the cold pressing unit 12 is controlled by the pneumatic booster cylinder 3 .

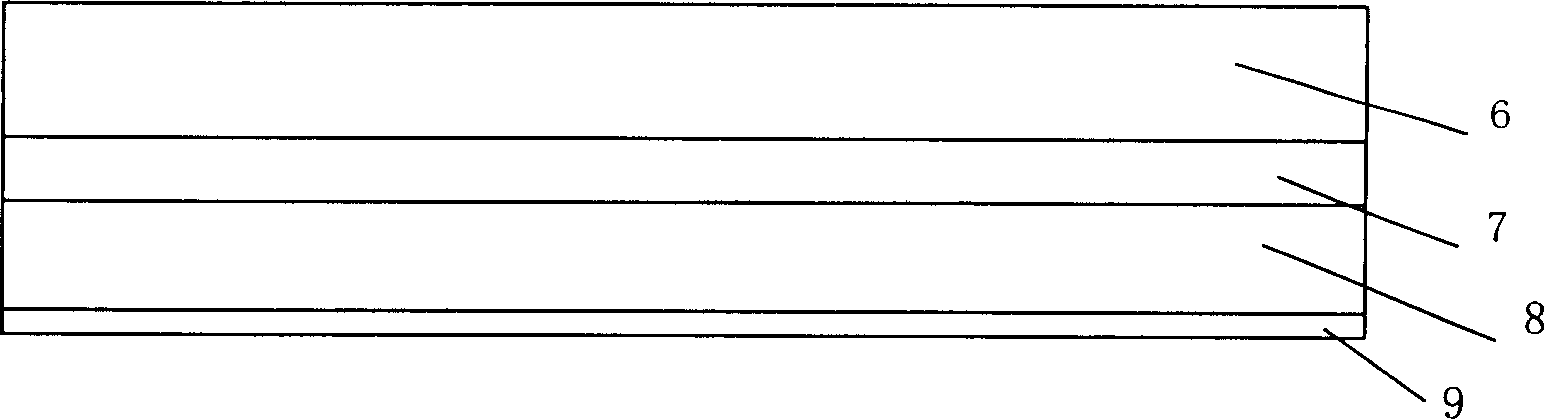

[0018] figure 2 It is a structural schematic diagram of the laminated board of the card making system of the present invention. The prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com