Mounting structure for split type grate shaker handle tube of motorcycle

A technology for installing structure and handlebar tube, which is applied in the field of directional control devices of motorcycles, can solve the problems of low stability, failure of circumferential positioning constraints of press-fit blocks and connecting plates, complicated assembly process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

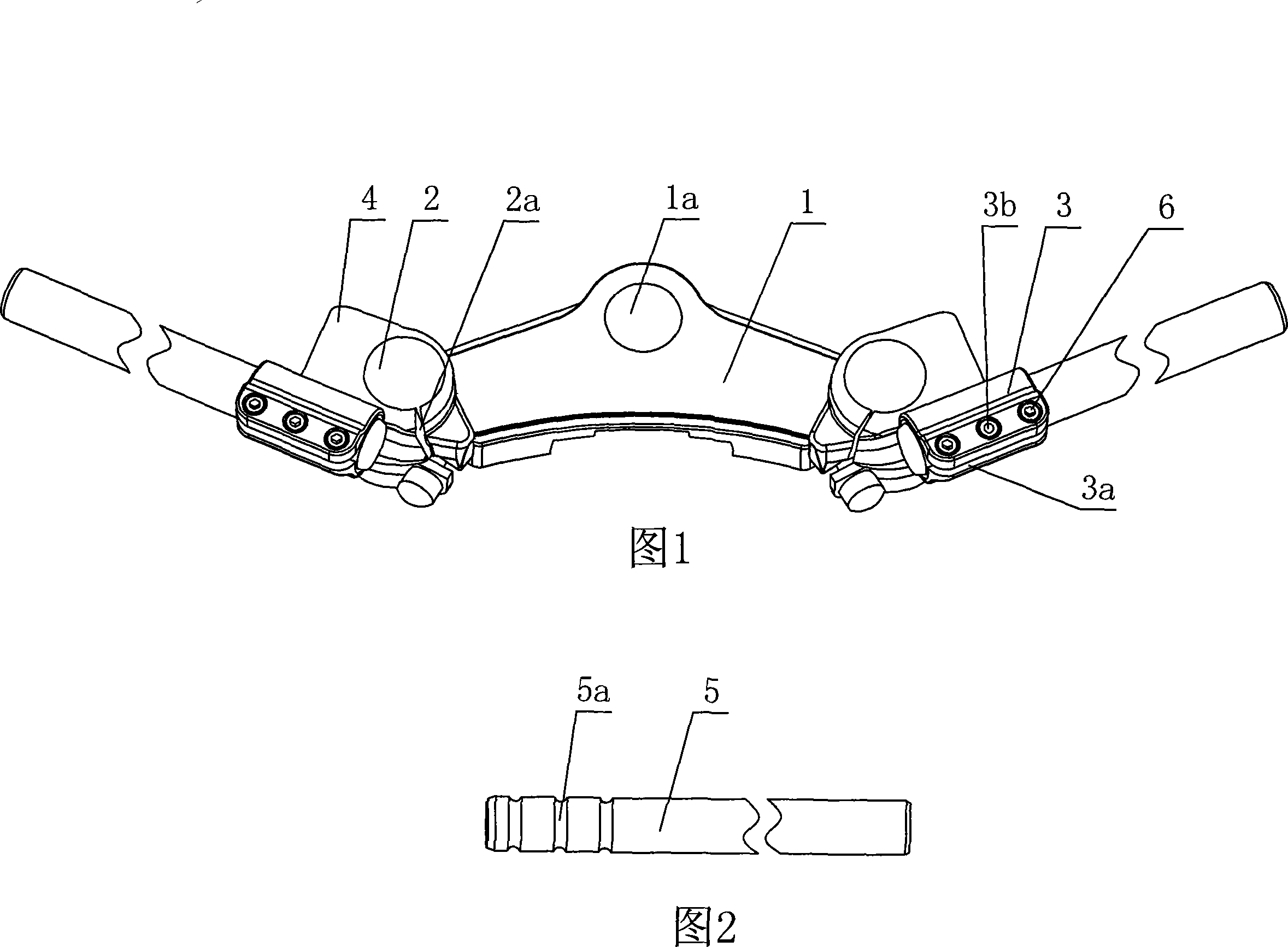

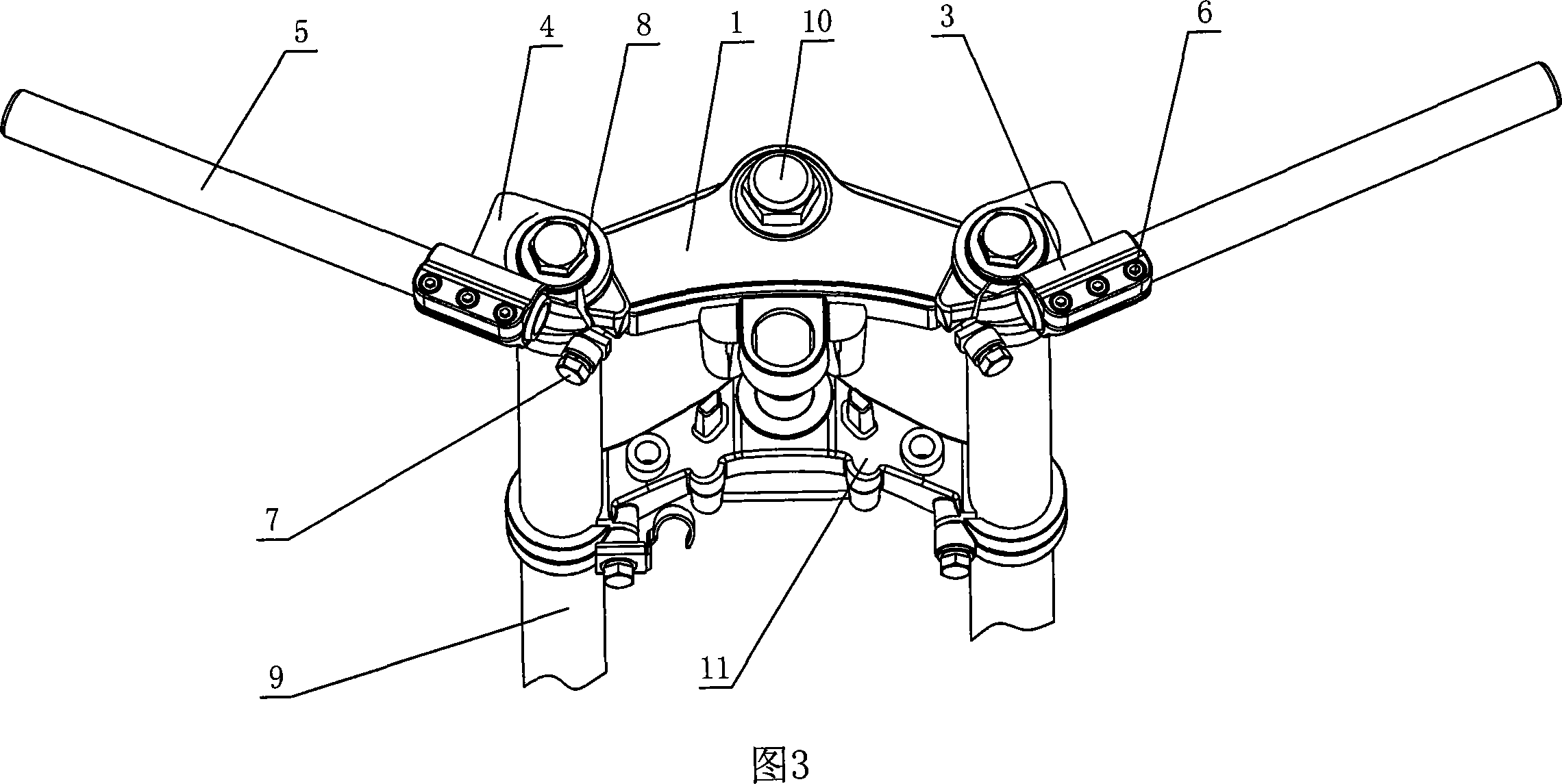

[0012] Referring to Fig. 1 to Fig. 3, the mounting structure of motorcycle split type handle pipe of the present invention, the left and right ends of upper connecting plate 1 are the mounting seat 4 for fixing front shock absorber 9 and handle pipe 5, and the mounting seat 4 is an integral structure formed integrally with the upper connecting plate 1, the mounting seat 4 protrudes from the surface of the upper connecting plate 1, and its thickness is higher than that of the upper connecting plate 1, so that the strength of the mounting seat 4 can be improved to ensure the firmness of the connection . The middle part of the upper connecting plate 1 is provided with a mounting hole 1a for installing the direction column 10 behind, and the mounting hole 1a is perpendicular to the plate surface of the upper connecting plate 1 in the axial direction; the mounting seats 4 at the left and right ends include holes for installing shock absorbers 2 and the opening jacket 3 for installi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com