Vehicle carrier of fork comb type multi-storied garage

A technology for a car transporter and a three-dimensional garage, which is applied to the field of a fork-comb lift three-dimensional garage car transporter, can solve the problems of increasing the access time of the car, affecting the time of accessing the car, and failing to realize the direct access to the car. The lifting mechanism is simple and reliable, the structure is simple, and the access time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

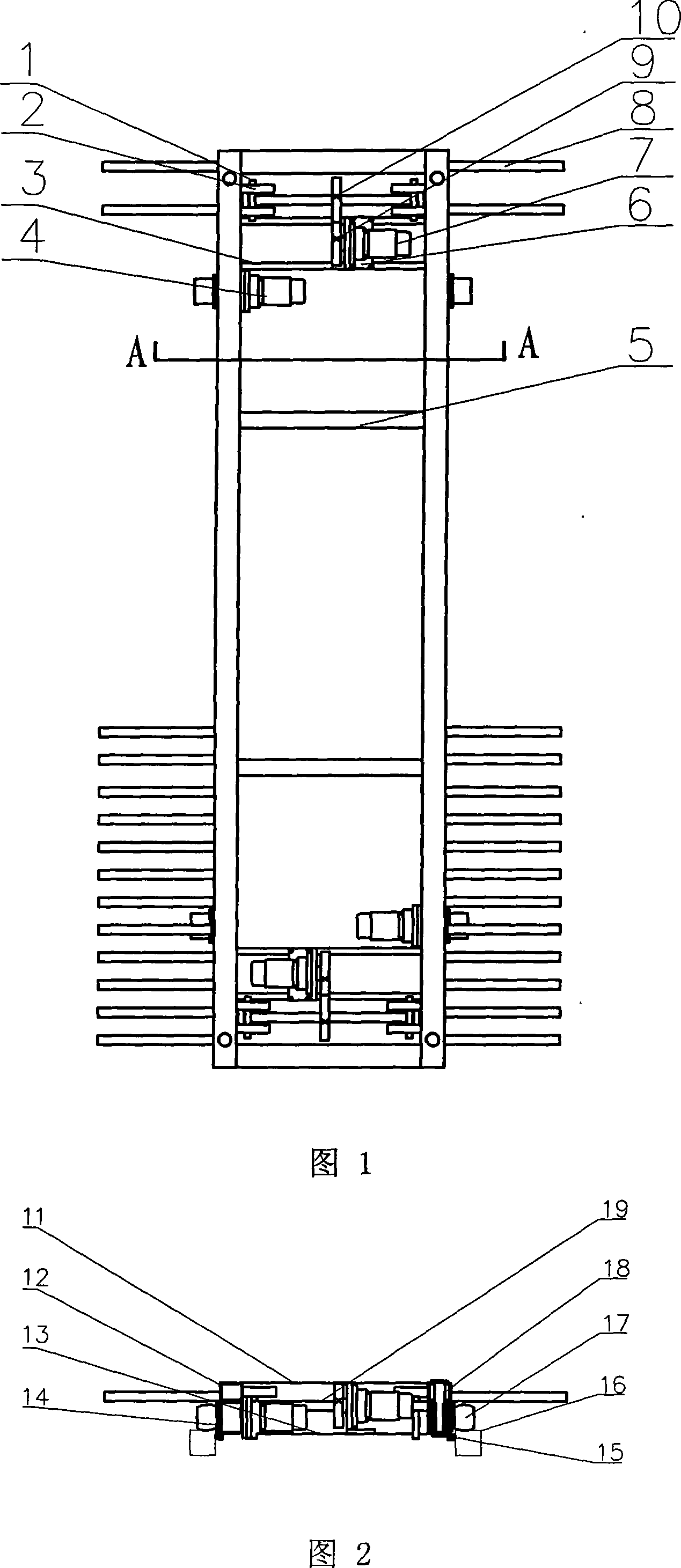

[0013] In Fig. 1 and Fig. 2, the underframe is welded by channel steel II14 and flat steel II13, two reinforcing plates 5 are welded in the middle of the underframe, four traveling wheels 17 are installed on the outside of the underframe, and the diagonal driving method is adopted, The running mechanism motor 4 is directly installed on the channel steel II14, and two guide wheels 15 are respectively installed on the two ends of the outer sides of the underframe rectangular steel 14, and its function is to ensure that the carrier does not deviate from the vehicle-carrying platform track 16; the lifting mechanism adopts a symmetrical arrangement, Weld the backing plate 3 at the bottom of the channel steel II14, the motor support 6 is connected to the backing plate 3, the lifting mechanism motor 7 is installed on the motor support 6, the motor 7 drives the gear I9, the gear I9 and the gear II10 installed on the gear shaft 19 Mesh, the eccentric wheel 1 is installed on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com