Vehicle complex spring equalization suspension device

A composite spring and balanced suspension technology, applied in suspension, vehicle parts, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

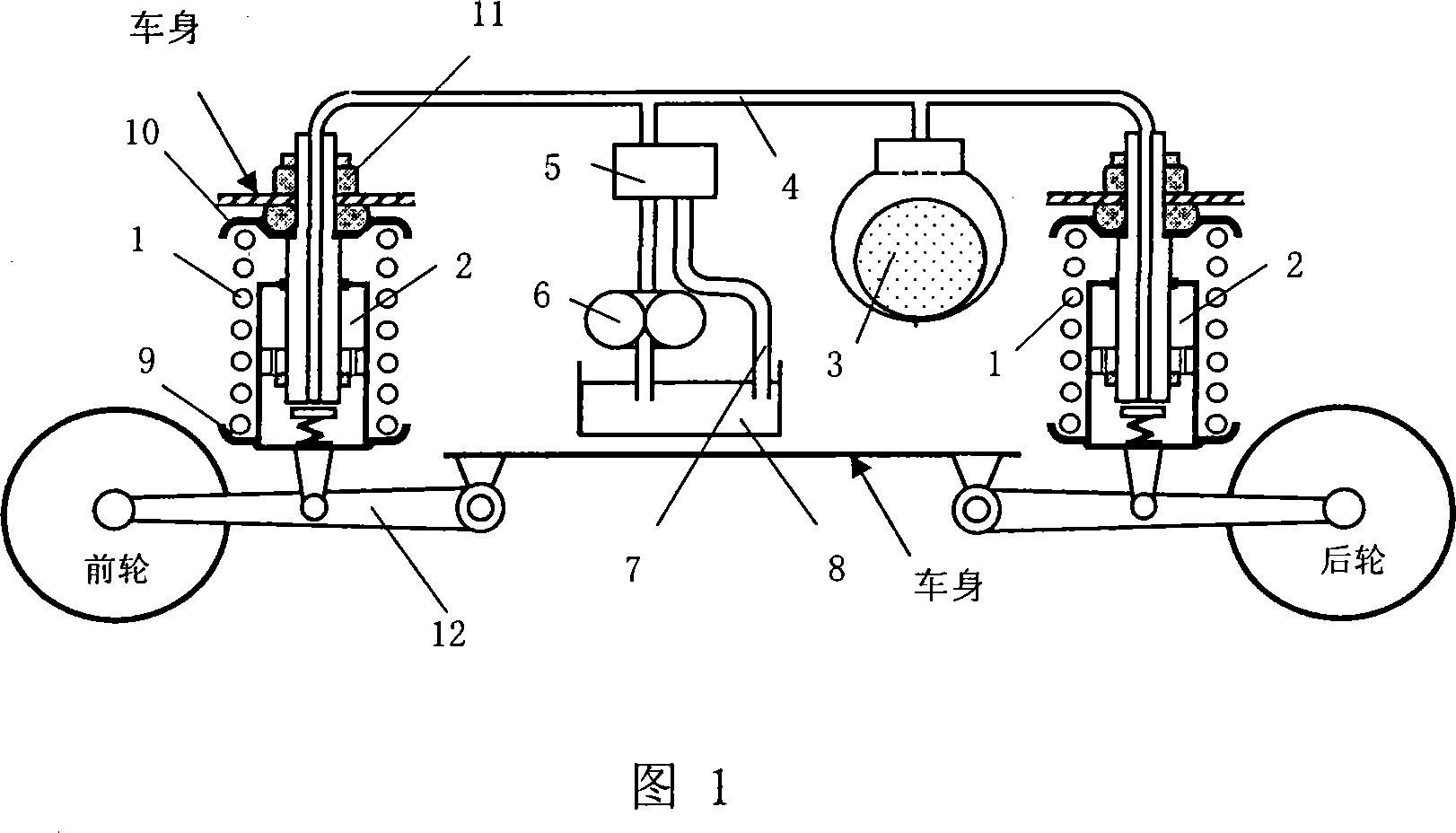

[0010] The structure of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] With reference to Fig. 1, a kind of vehicle composite spring balanced suspension device, comprises the guide arm 12 that is arranged on each wheel axle and is hinged with vehicle body, accumulator 3, helical spring 1 and oil-pneumatic spring 2, in each described guide Arms 12 are respectively provided with a set of composite spring support composed of the coil spring 1 and the oil-pneumatic spring 2 and connected to the vehicle body; the oil cylinders of the oil-pneumatic spring 2 on the front and rear wheel guide arms on the same side are connected through the pipeline 4, And connect a described accumulator 3 on this pipeline 4 .

[0012] Each set of composite springs is to consolidate the lower pallet 9 at the bottom of its oil-gas spring 2, and its coil spring 1 is seated on the lower pallet 9, and the upper end of the coil spring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com