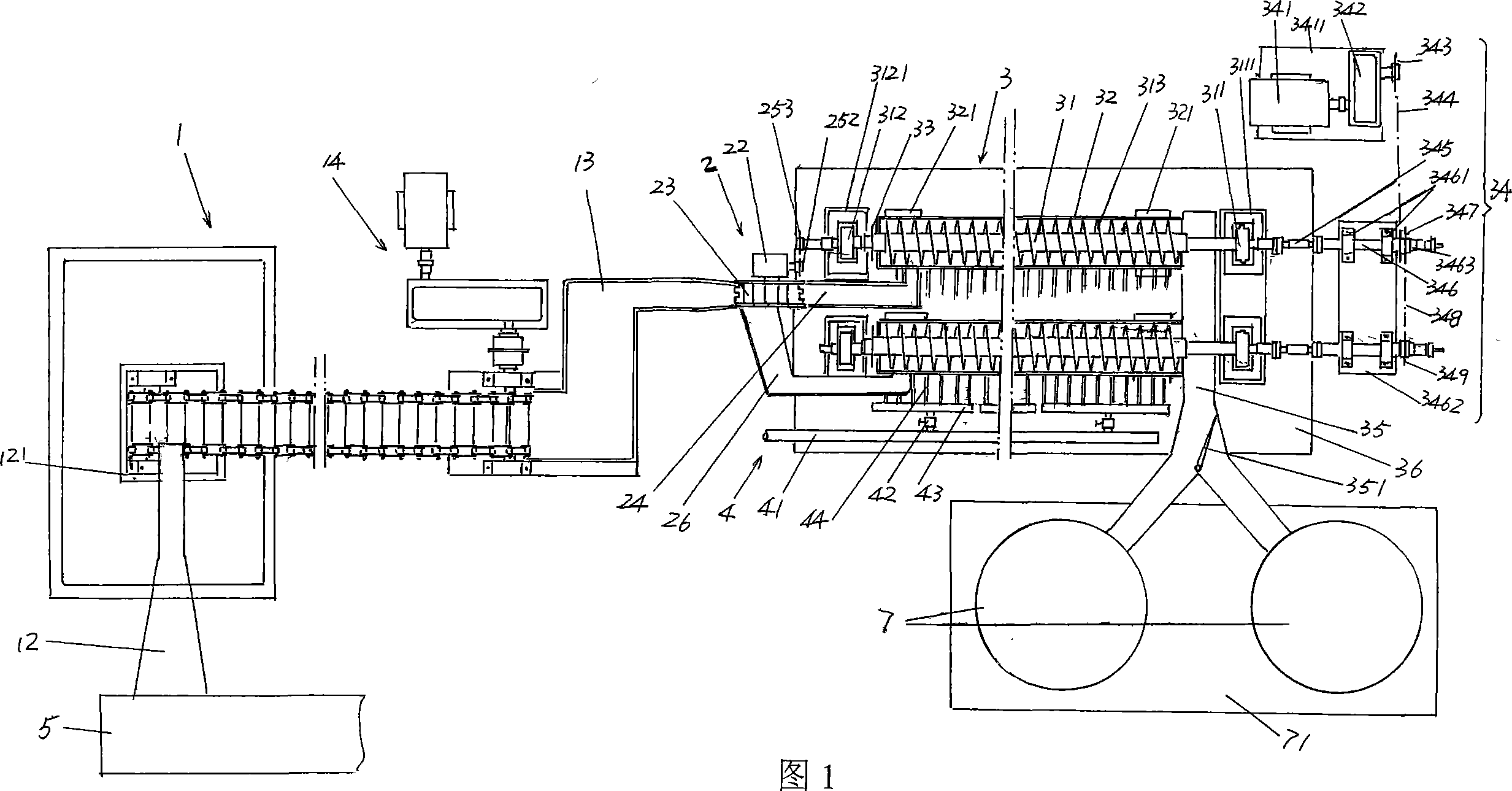

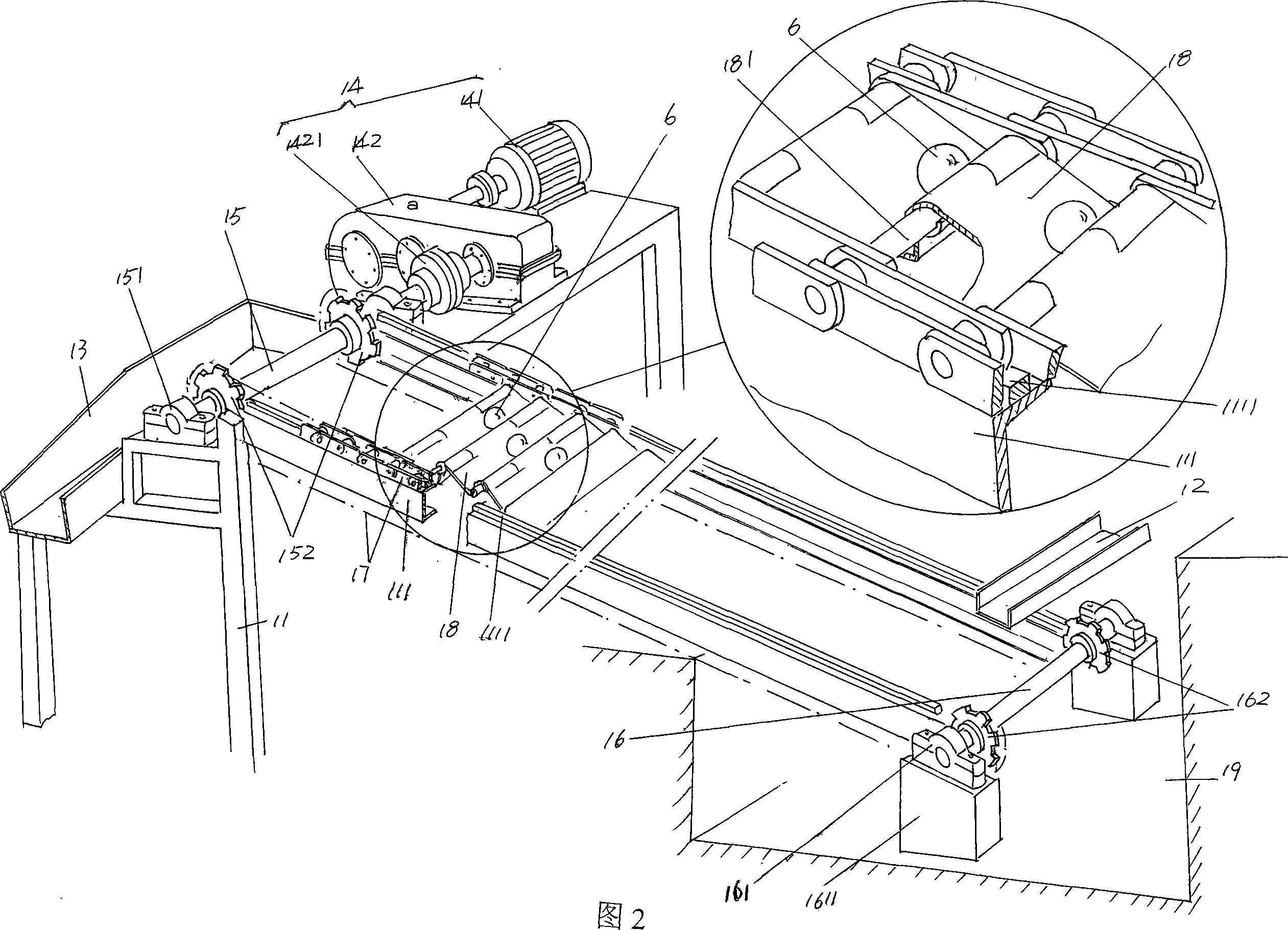

Steel ball quenching machine

A quenching machine and steel ball technology, applied in the field of steel ball quenching machine, can solve the problems of low ball milling efficiency, frequency, poor physical properties of steel balls, etc., and achieve the effect of improving quenching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

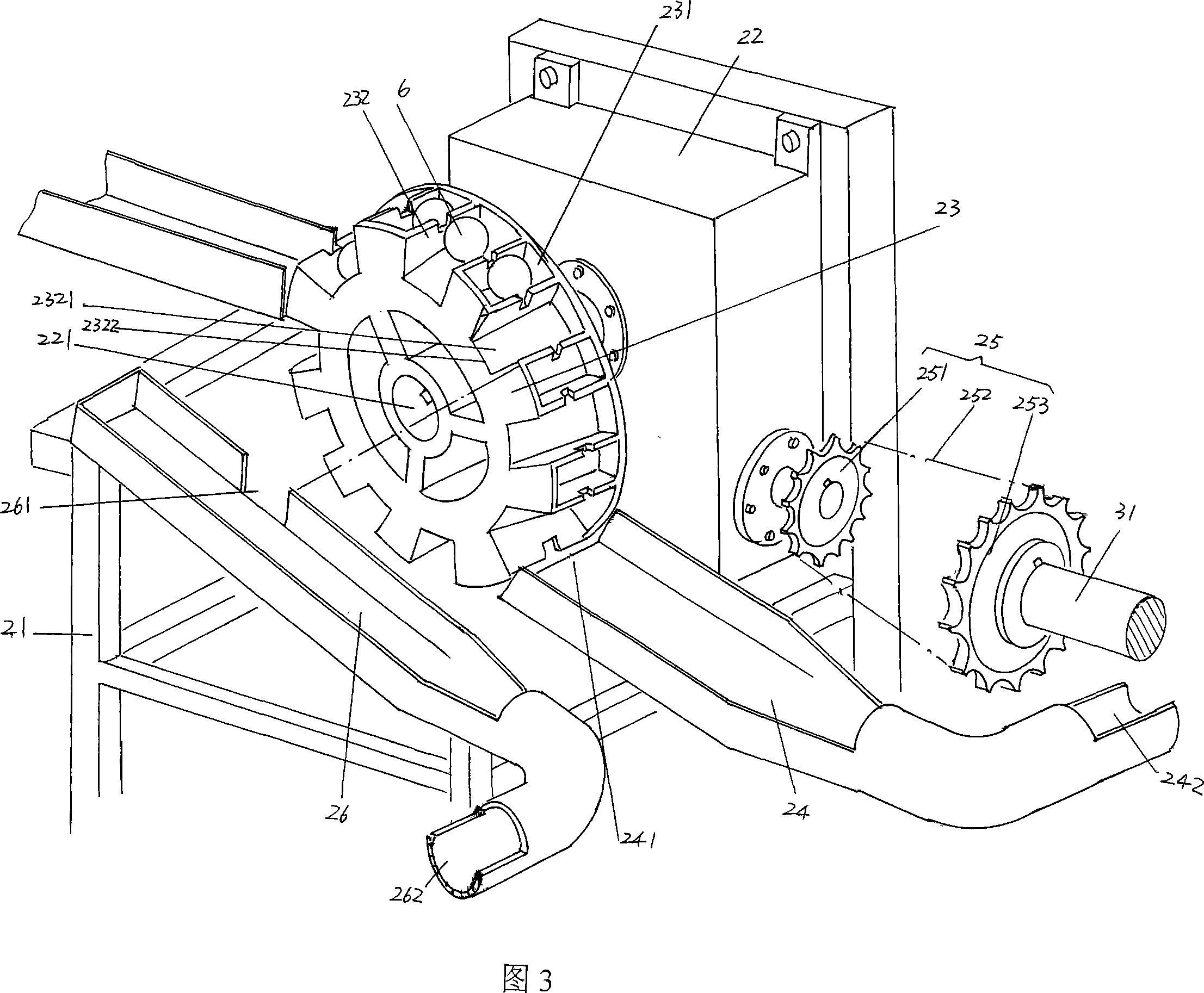

[0031] Please refer to Fig. 5, have provided the example that is only a set of steel ball helical partition quenching mechanism 3, in this case, only need central raceway 24 as the ball feeding raceway of feeding mechanism 2, and steel The second ball outlet 2322 of the side road storage ball chamber 232 on the ball diversion plate 23 is closed, forming the same structural form as the middle road storage ball chamber 23. And, there is no transition chain 348 present. And, only one set of quenching medium conveying mechanism 4 is needed, and the rest are the same as the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com