Casing lid binding structure of barrel washing machine

A drum washing machine and casing cover technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of large distance between installation positions, 20 variants of the casing cover, and increased product defect rate, so as to improve installation Strength, effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The casing cover combination structure of the drum washing machine of the present invention will be described in detail below with reference to the accompanying drawings.

[0030] For ease of understanding, the parts in the figure that have the same structure as the existing drum washing machine use the same reference numerals.

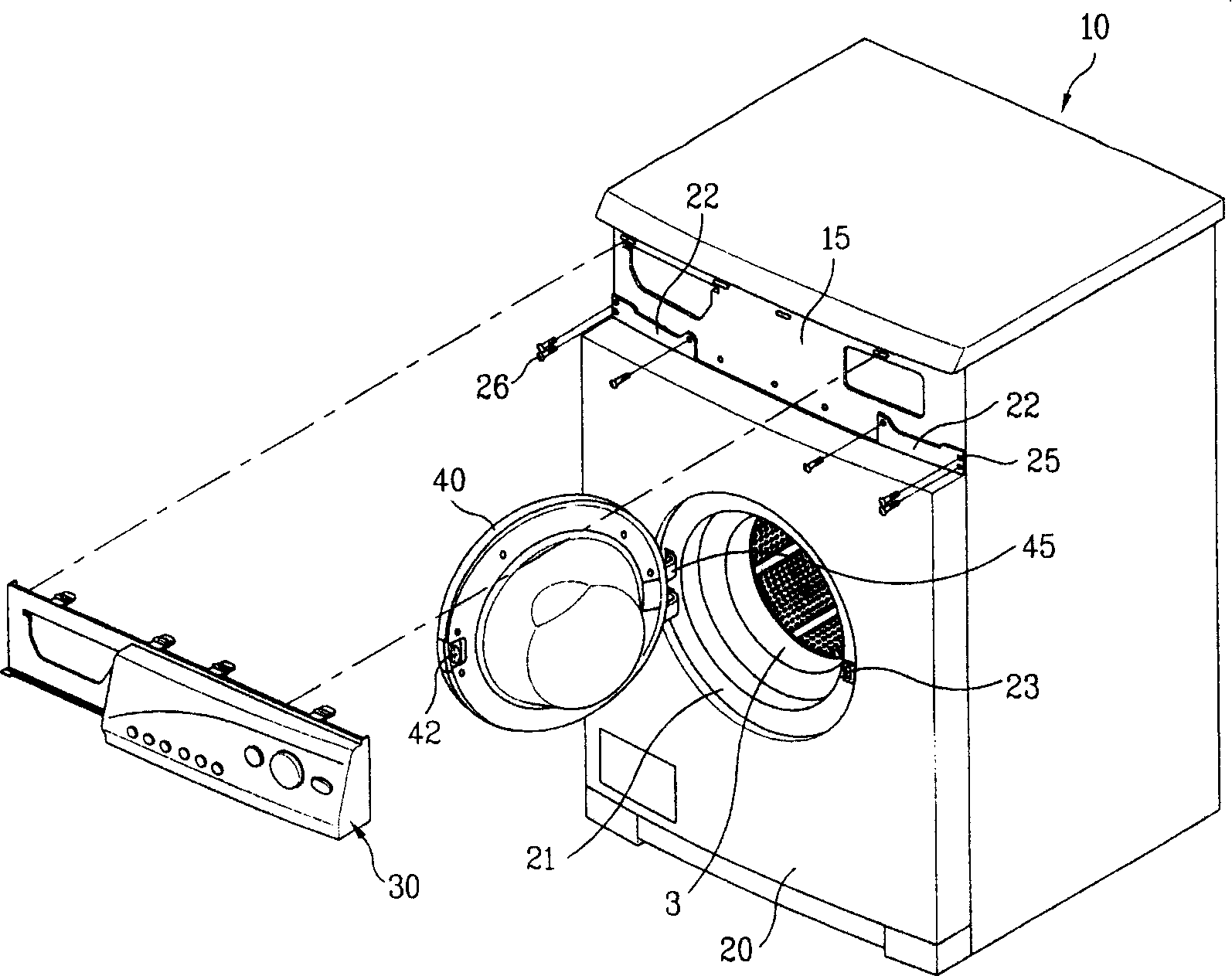

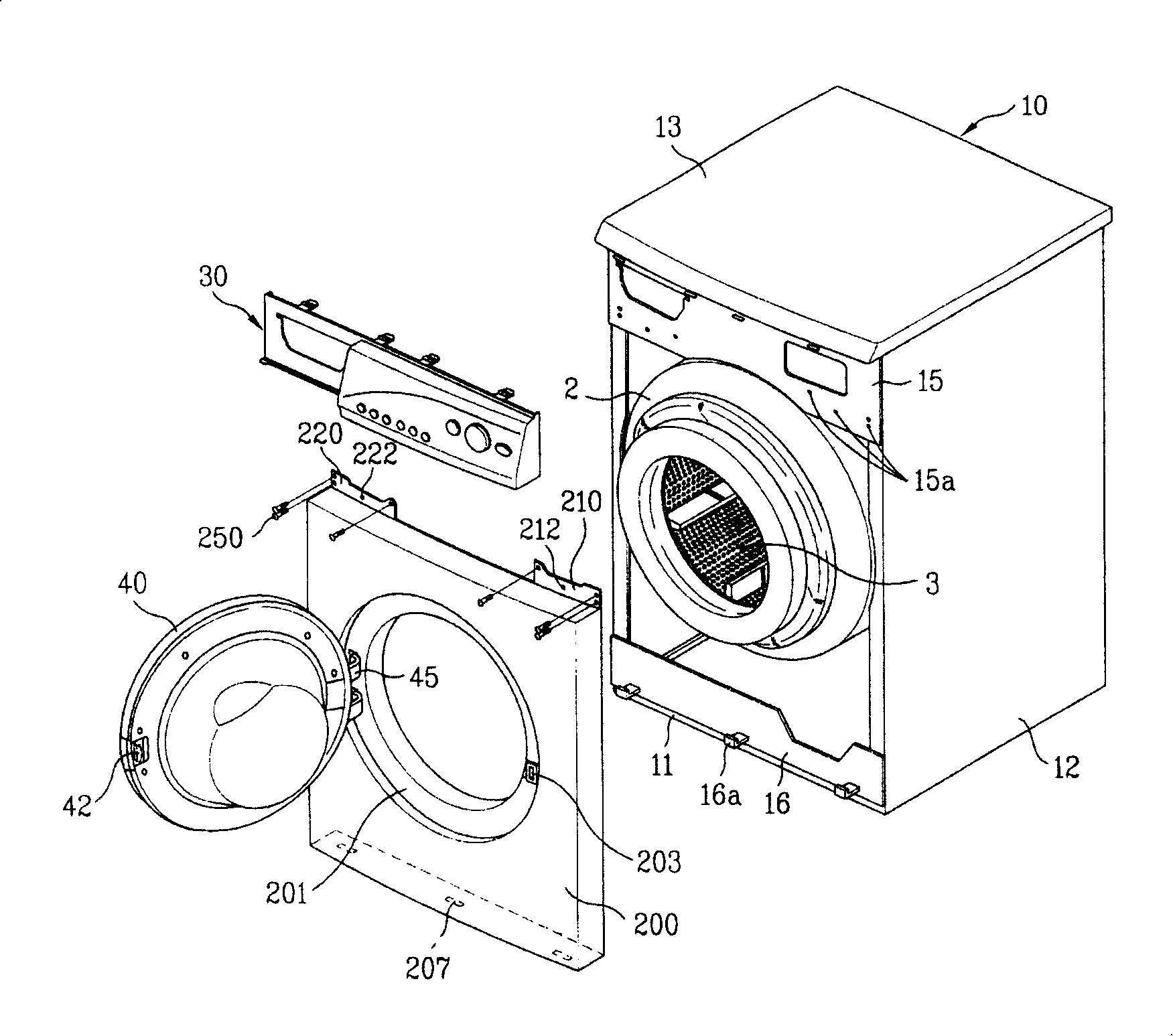

[0031] see image 3 and Figure 4 A washing tub 2 for storing washing water is arranged inside the casing main body 10 constituting the main body of the drum washing machine, and a drum 3 is arranged inside the washing tub 2 . The drum 3 rotates under the action of a motor (not shown). The casing main body 10 is composed of two opposite side casings 12, a rear casing (not shown) and an upper casing 13. The front of the casing main body 10 is open, and an organic casing is combined at the open part. Cover 200.

[0032] An upper bracket 15 and a lower bracket 16 are respectively provided at the upper end and the lower end of the casing main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com