Washing machine

A washing machine and washing tub technology, applied in the field of washing machines, can solve the problem that it is difficult to increase the depth and depth of the detergent input portion, and achieve the effects of preventing accumulation and preventing water leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] An embodiment of the present invention will be described below with reference to the drawings.

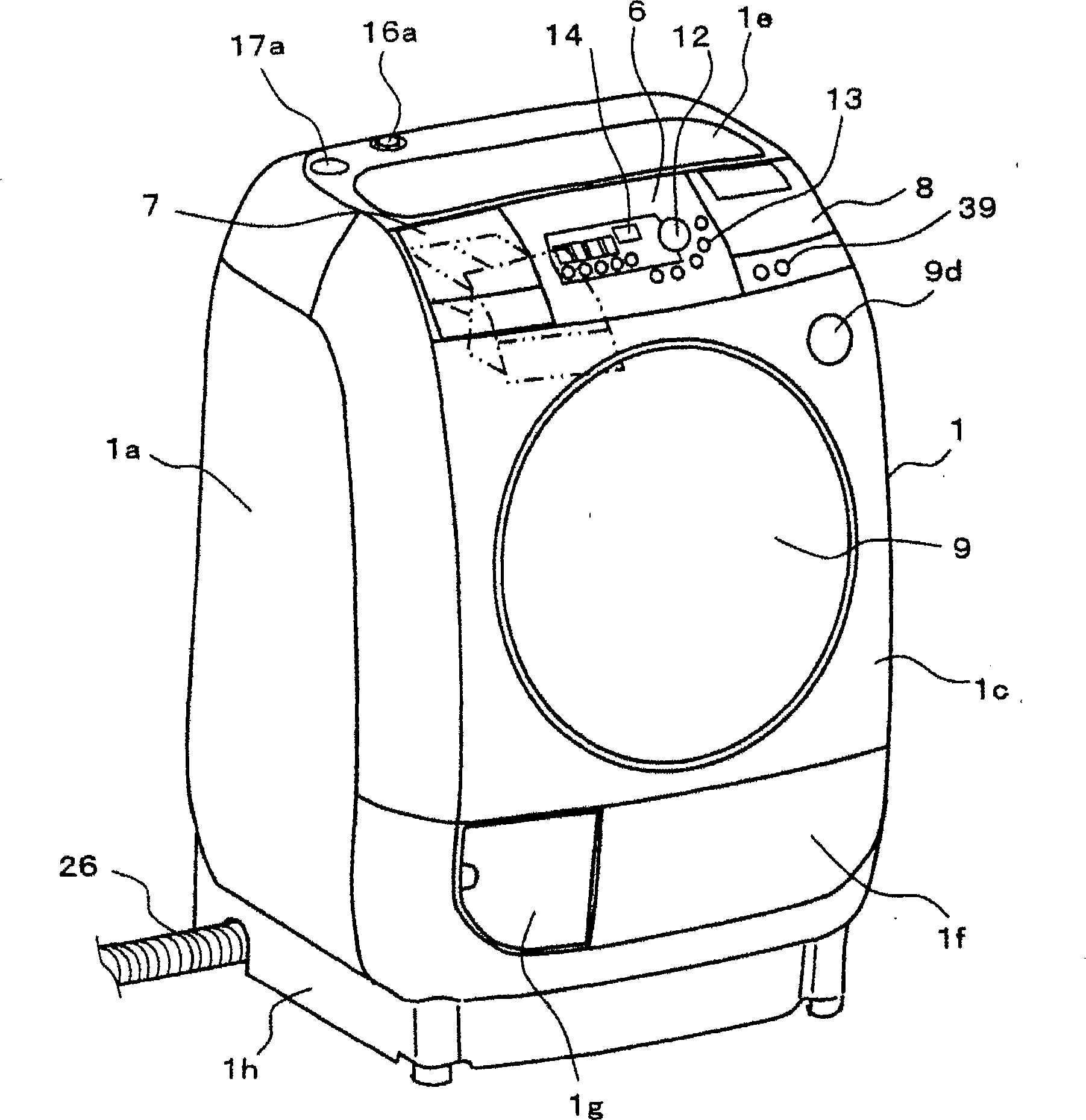

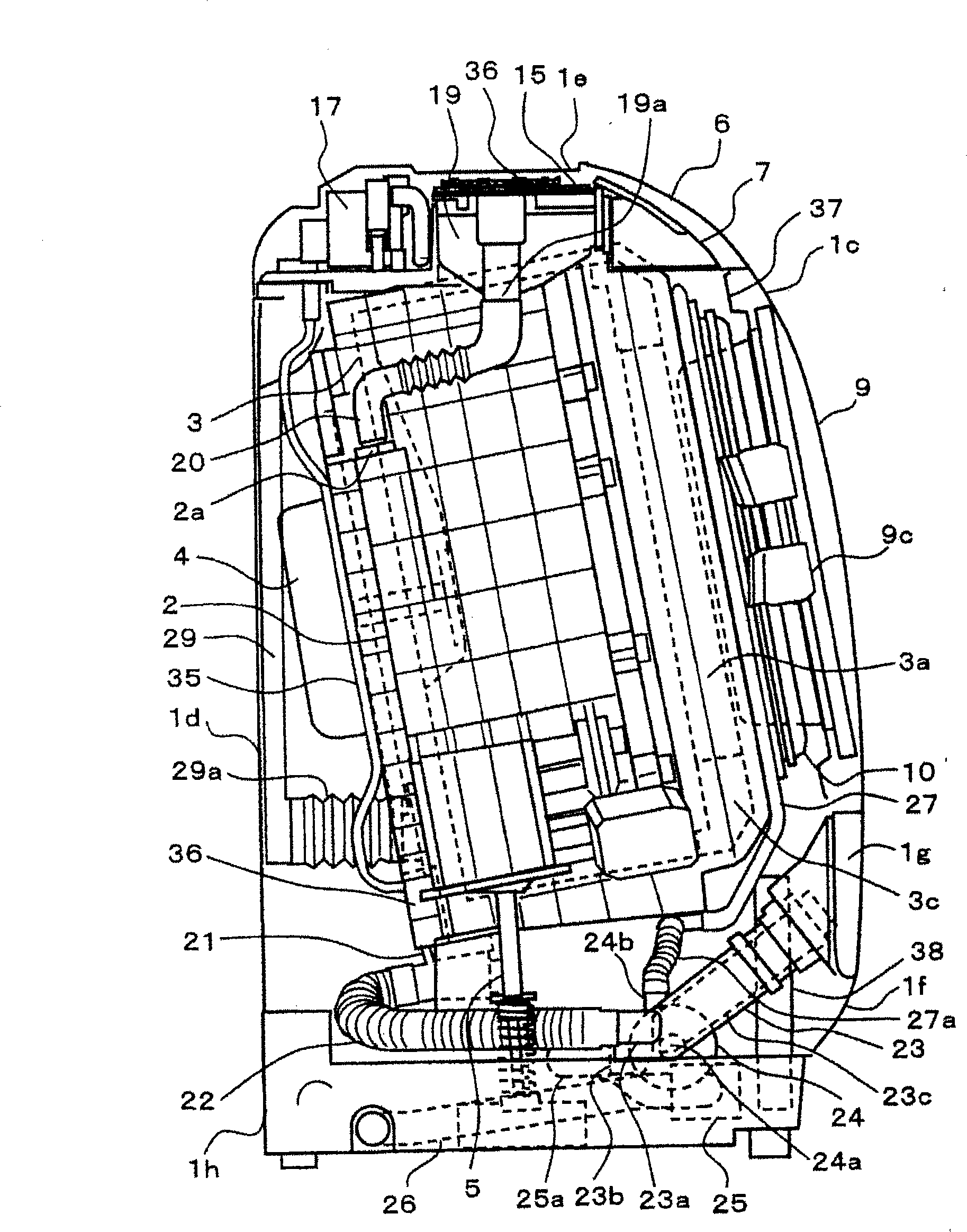

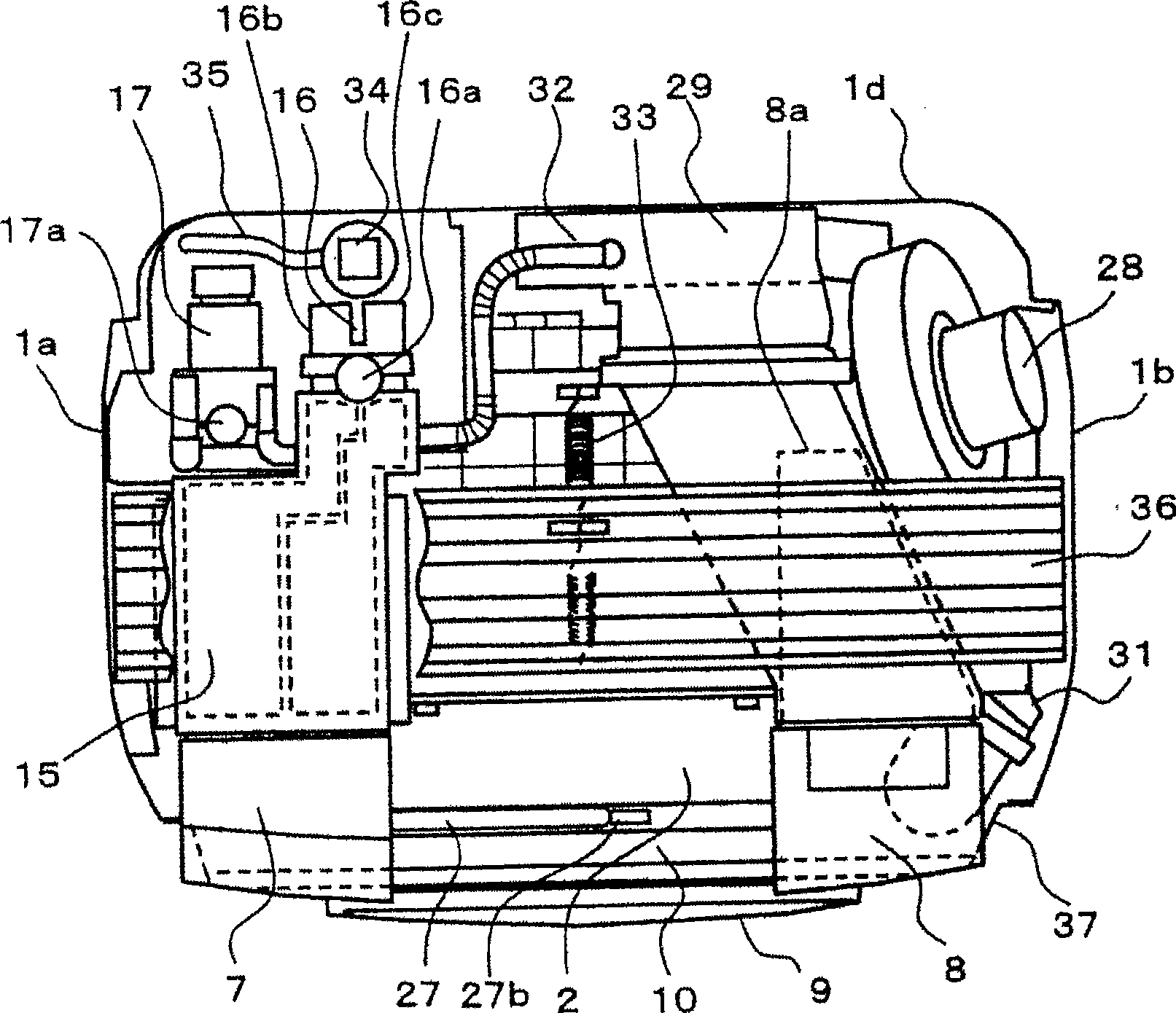

[0038] figure 1 It is an external view of the front-loading-type washing machine concerning one Embodiment of this invention. figure 2 is a side view showing the internal structure, image 3 It is a plan view showing the internal structure (shown by cutting off a part of the upper reinforcement 36), Figure 4 It is a partial front view of the upper left side showing the internal structure.

[0039] 1 is the housing forming the outer contour. The casing 1 is mounted on a base 1h, and is composed of left and right side panels 1a, 1b, a front cover 1c, a rear cover 1d, a top cover 1e, and a lower front cover 1f. The left and right side plates 1a, 1b are combined with a U-shaped upper reinforcement 36, a front reinforcement 37, and a rear reinforcement (not shown), and a box-shaped housing 1 is formed including the base 1. As the housing, enough strength.

[0040] Referen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com