Single steam turbine key components and parts low-cycle fatigue service-life management system and management method

A low-cycle fatigue and life management technology, applied in the field of steam turbines, can solve the problems of inconvenient use and maintenance and high investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

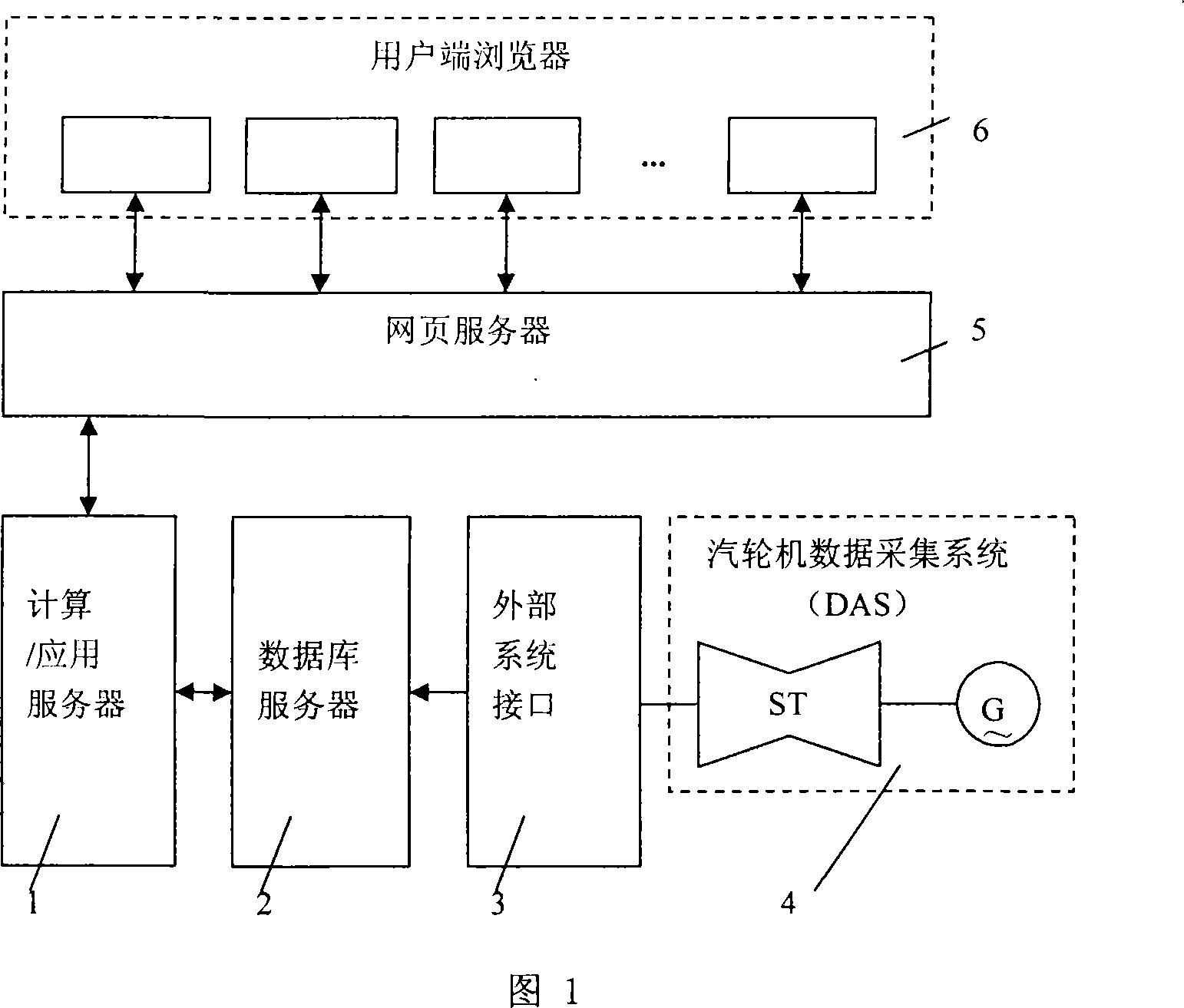

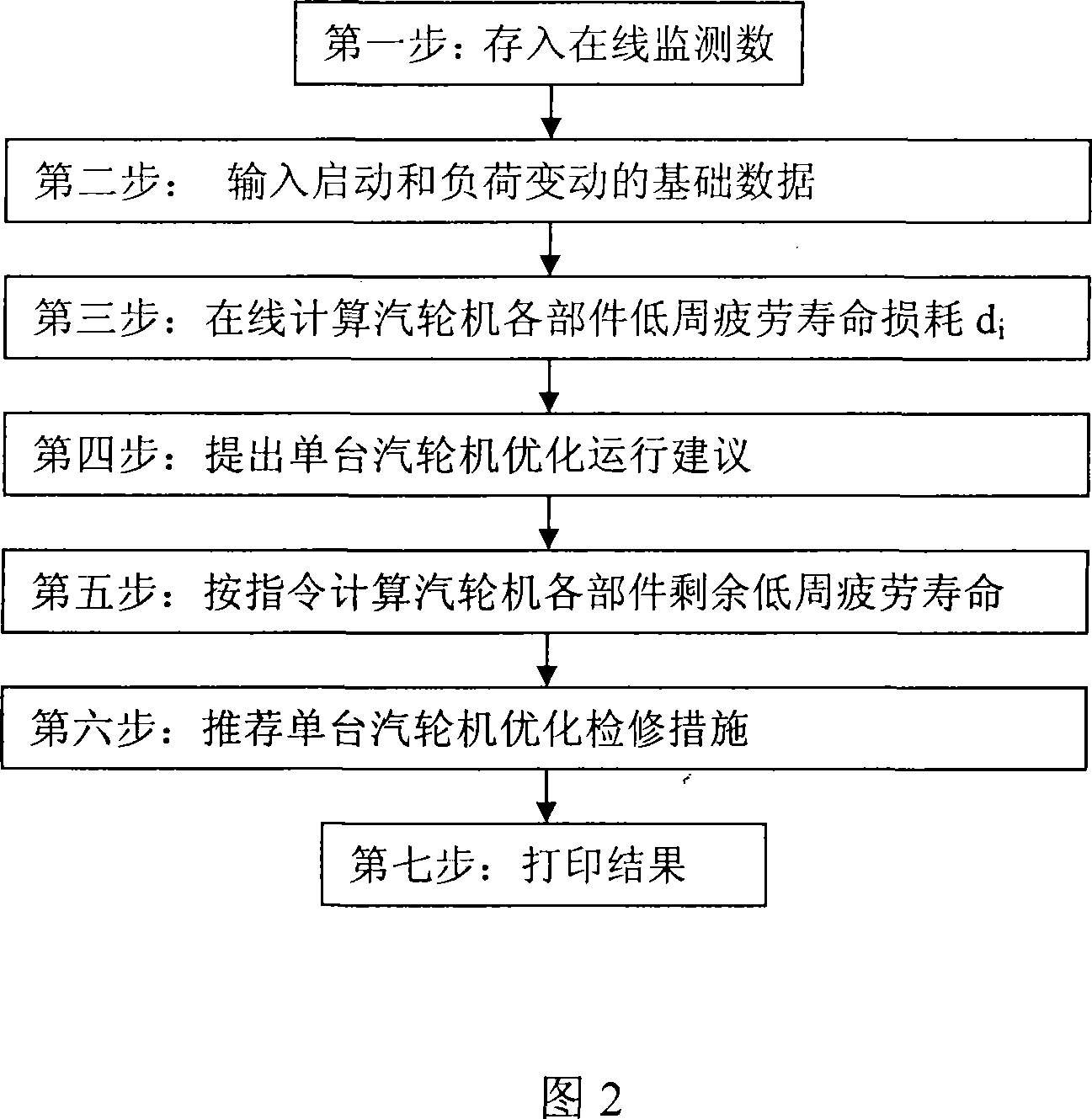

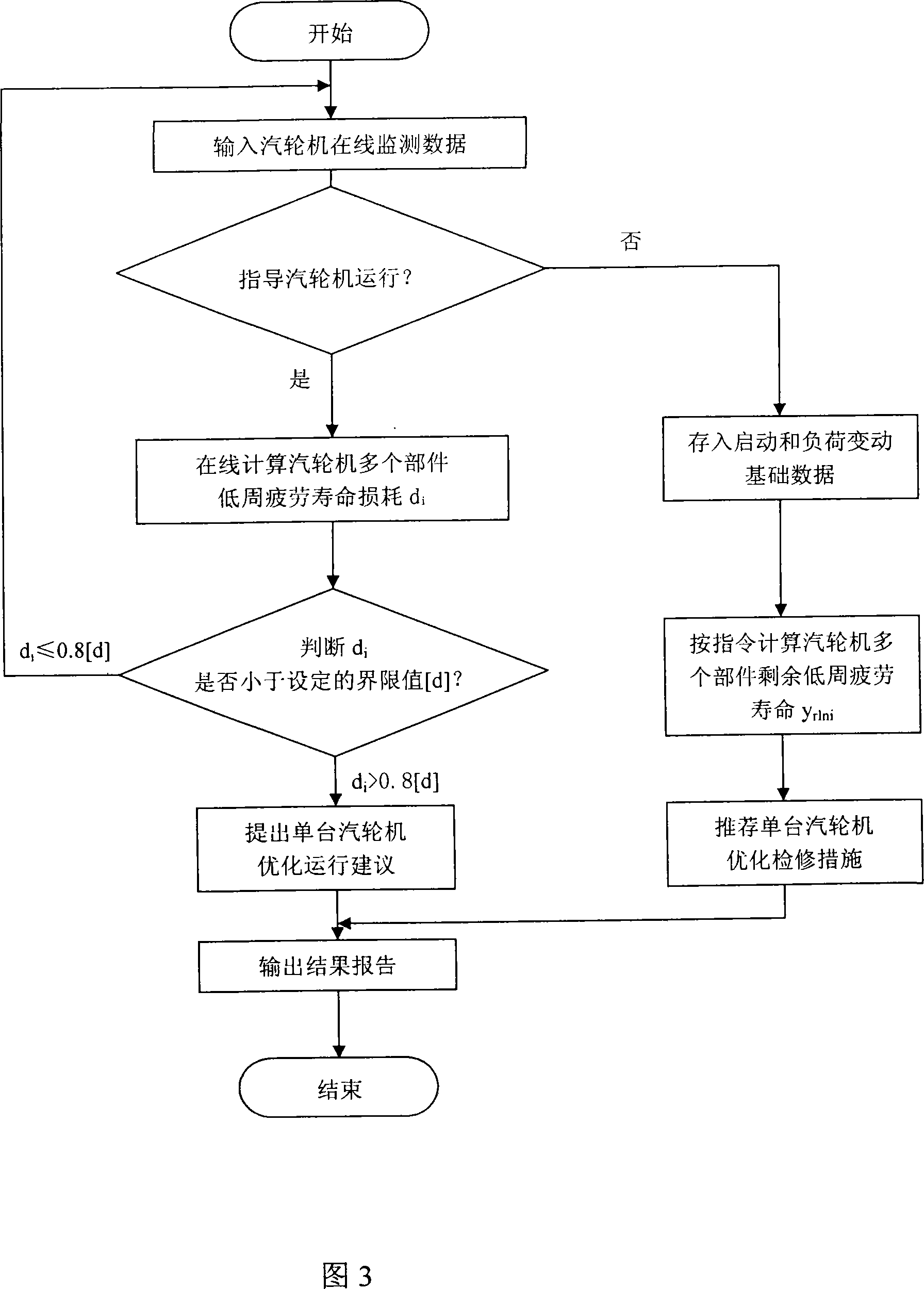

[0054] For the high and medium pressure rotors, main steam valve casings and low pressure rotors of a subcritical 300MW steam turbine with an inlet steam temperature of 538°C, the low cycle fatigue life management system shown in Figure 1 and the present invention shown in Figure 2 are used to provide The flow chart of the method and the computer software for low-cycle fatigue life management of multiple components of the steam turbine shown in Figure 3, and the predicted results of the calculated remaining low-cycle fatigue life of the steam turbine are listed in Figure 4.

[0055] The first step: every Δτ=3 minutes, the steam turbine speed, unit power, steam pressure before the main steam valve, and steam temperature before the main steam valve in the measuring point data of the 300MW steam turbine data acquisition system DAS 4 are collected through the external system interface 3 , steam temperature after regulating stage, metal temperature of high-pressure inner cylinder at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com