Method for producing oxygen-free high conductivity type copper strip

A production method and technology for oxygen-free copper are applied in the production field of high-conductivity oxygen-free copper strips, which can solve the problems of infiltration, environmental pollution, and high equipment requirements, and achieve the effects of low production cost, low investment, and pollution avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention is described below:

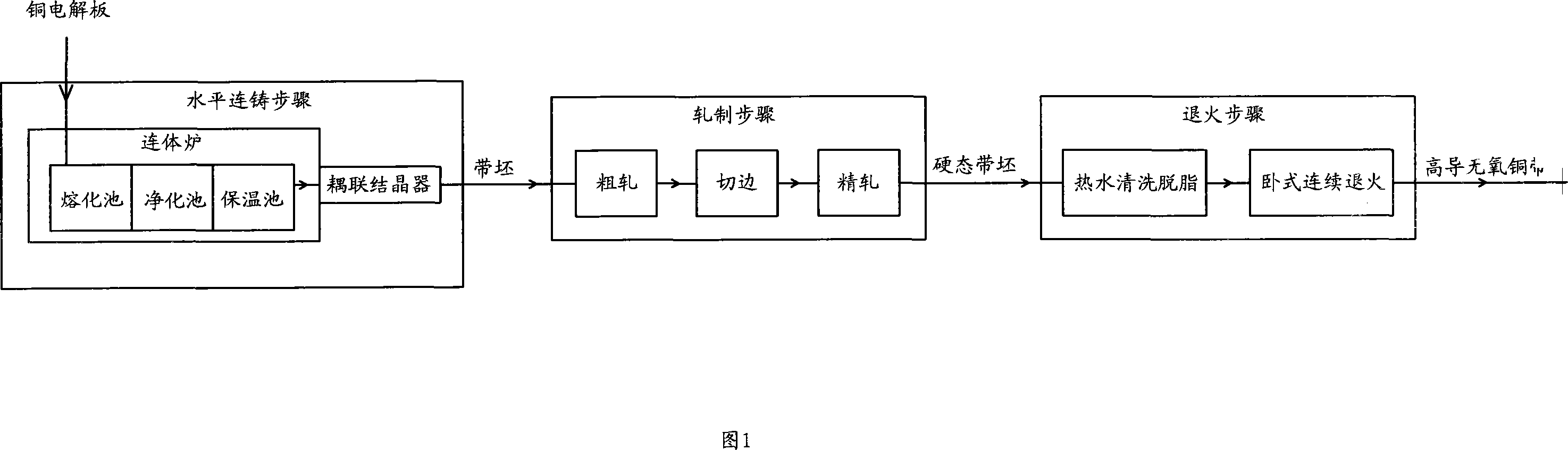

[0027] A grade A copper electrolytic plate is selected as the raw material, and the electrolytic plate is immersed in the conjoined furnace 250 of the horizontal continuous casting unit. The one-piece furnace 250 is separated by the pool wall into a melting pool 210 , a purification pool 220 and a heat preservation pool 230 which are successively adjacent. A first channel 215 is provided at the bottom of the pool wall between the melting pool 210 and the purification pool 220 , and a second channel 225 is provided at the bottom of the pool wall between the purification pool 220 and the heat preservation pool 230 .

[0028] The copper water can pass through the first channel 215 and the second channel 225 to flow through the melting pool 210 , the purification pool 220 and the heat preservation pool 230 sequentially without additional pouring process of the copper water.

[0029] The electrolytic pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap