Plane abrasive belt glazing machine

A belt grinder and plane technology, applied in the mechanical field, can solve the problems of low work efficiency and achieve the effect of simple structure, low cost and high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

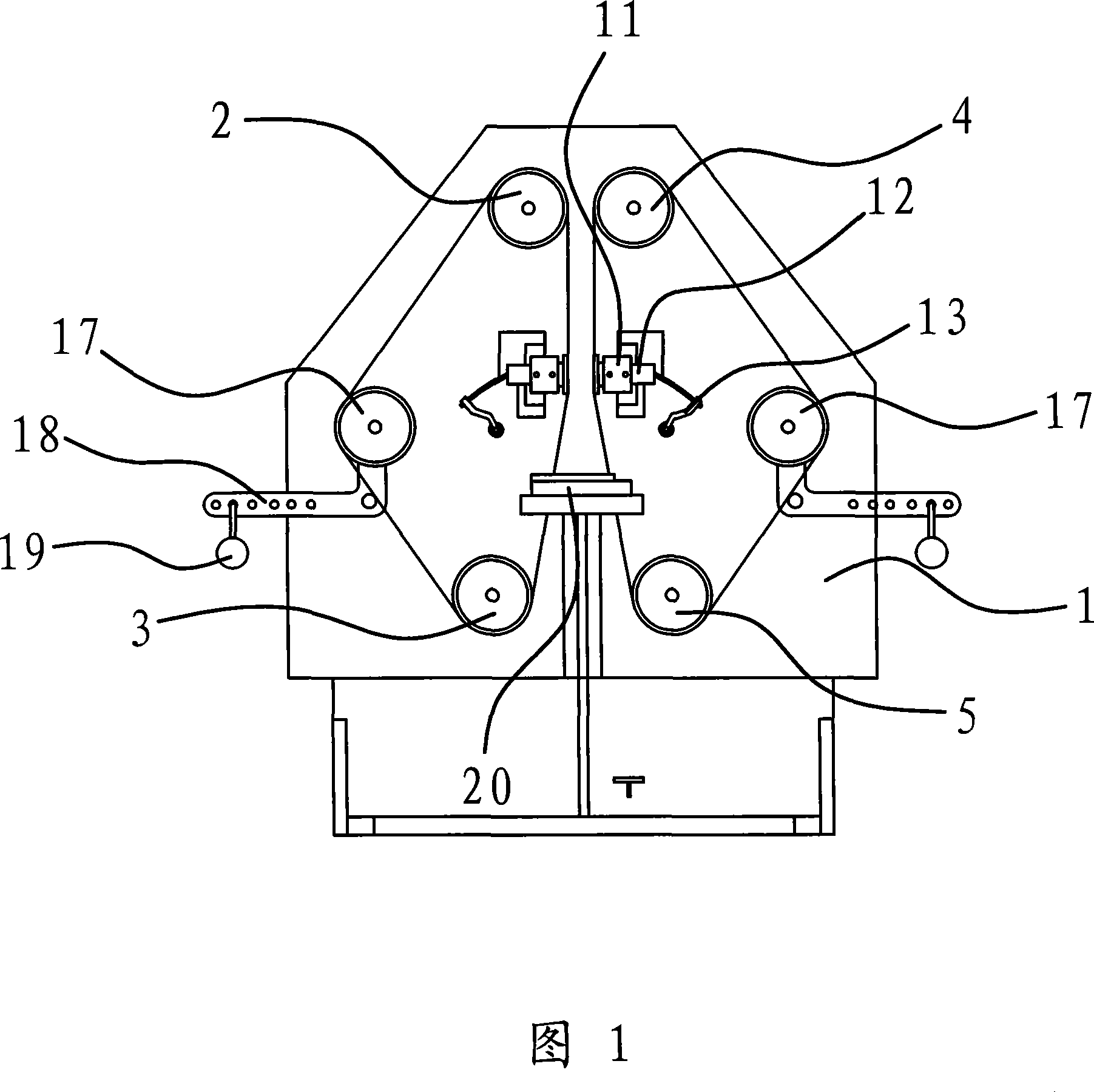

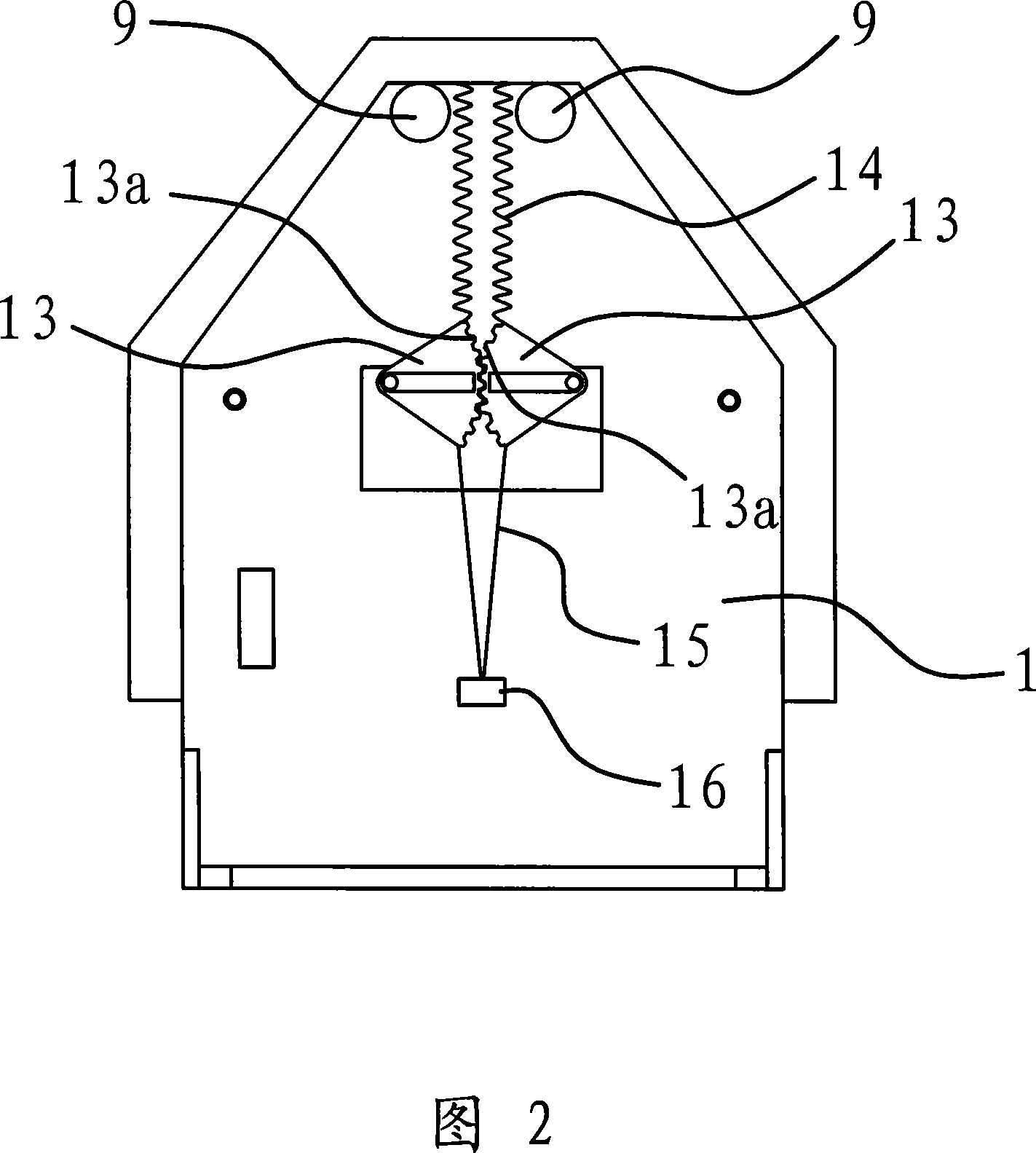

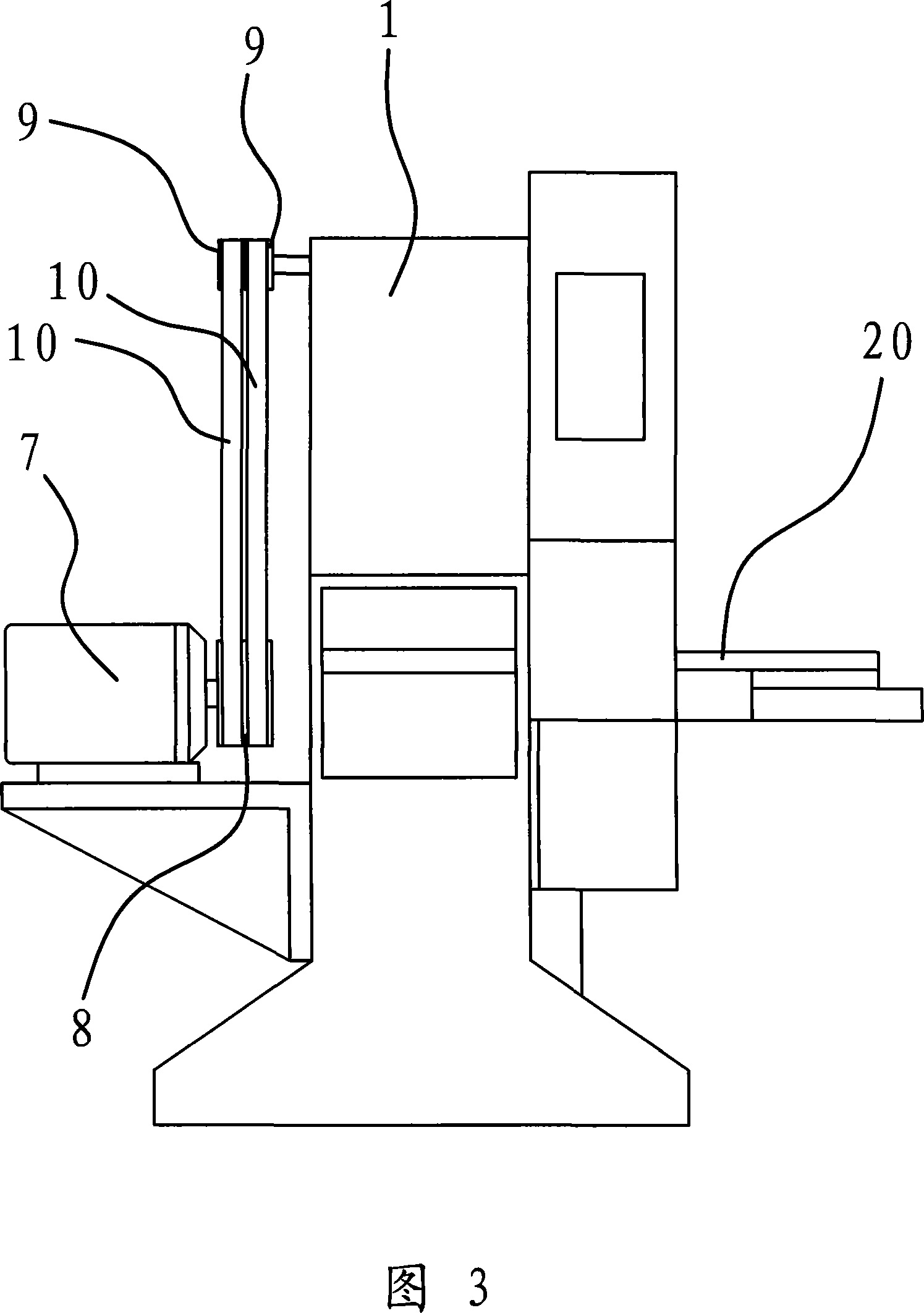

[0027] As shown in Fig. 1 and Fig. 2 and Fig. 3, this plane abrasive belt sander comprises a frame 1, is provided with driving wheel one 2, driven wheel one 3, driving wheel two 4, driven wheel two on frame 1 5 and two abrasive belts 6.

[0028] Driving wheel-2 and driven wheel-3 are all connected on the frame 1, and they all can rotate, and driving wheel-2 links with power unit. Driving wheel two 4 and driven wheel two 5 are also connected on the frame 1, and they are also rotatable, and driving wheel two 4 is connected with power unit. In this embodiment, the power device is a motor 7, a driving pulley 8, a driven pulley 9 and a transmission belt 10, the driving pulley 8 is fixed on the rotating shaft of the motor 7, and the driven pulley 9 is fixed on the above-mentioned driving pulley On one 2 or driving pulley two 4, transmission belt 10 is enclosed within on driving pulley 8 and driven pulley 9, sees shown in Figure 4.

[0029] Wherein an abrasive belt 6 is enclosed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com