Restored reinforcing wheel and restoring technique therefor

An enhanced wheel technology, applied in the direction of wheels, metal processing equipment, and wheels characterized by rail running parts, can solve problems such as large quantities, driving safety threats, and economic waste, and achieve huge value, comprehensive performance improvement, and The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

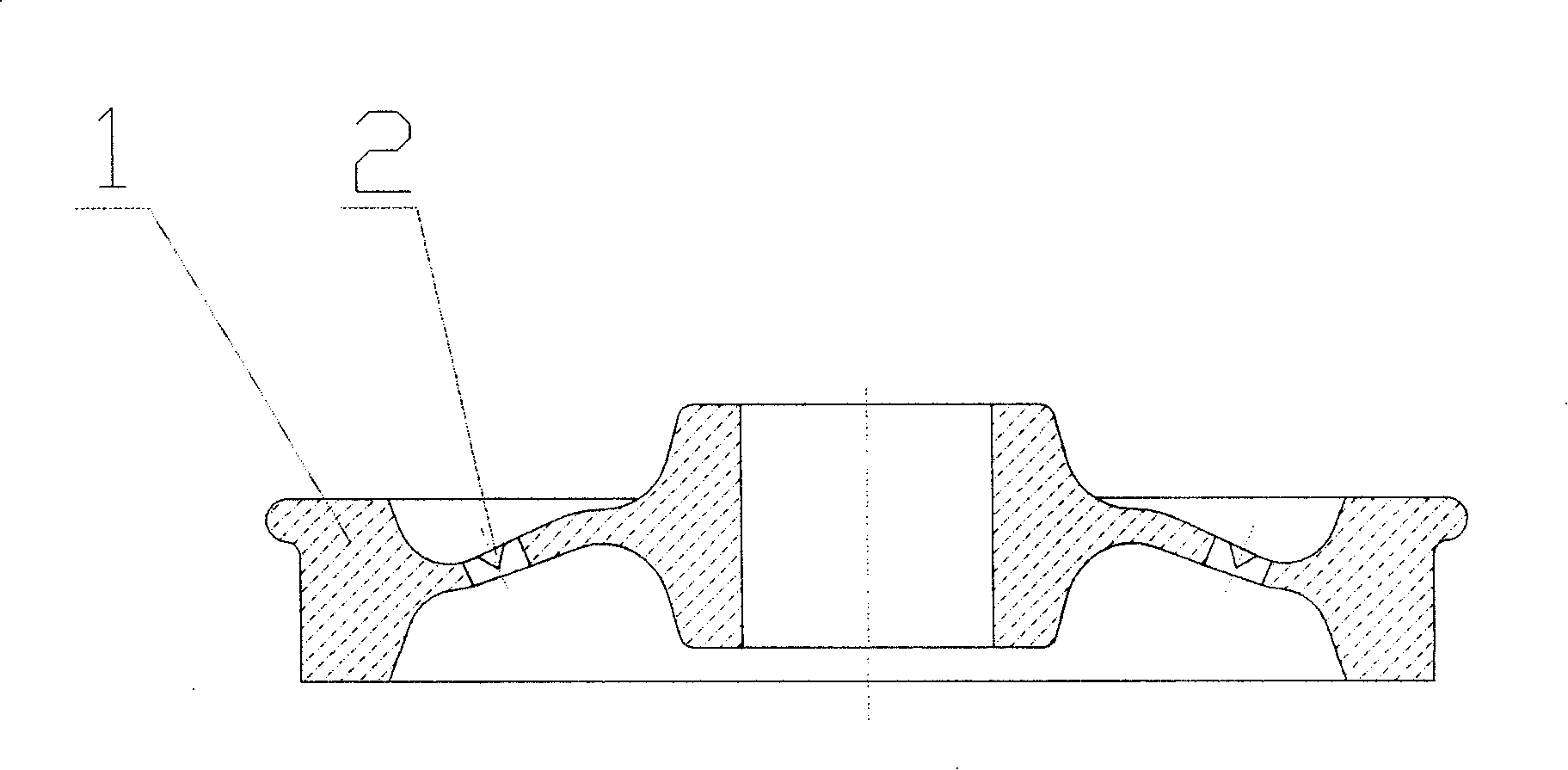

[0029] Example 1 Repaired Reinforced Wheel with Wedge Reinforcement

[0030] The structure of the repaired reinforced wheel with wedge-shaped reinforcement is as follows figure 1 As shown, it consists of a railway wheel 1 and a wedge-shaped reinforcement 2 . The wedge-shaped reinforcements 2 are inserted into the web holes of the railway wheel 1 . The material of the railway wheel 1 is medium carbon alloy steel, and the material of the wedge-shaped reinforcement 2 is a nickel-based alloy with a higher strength than the base material.

Embodiment 2

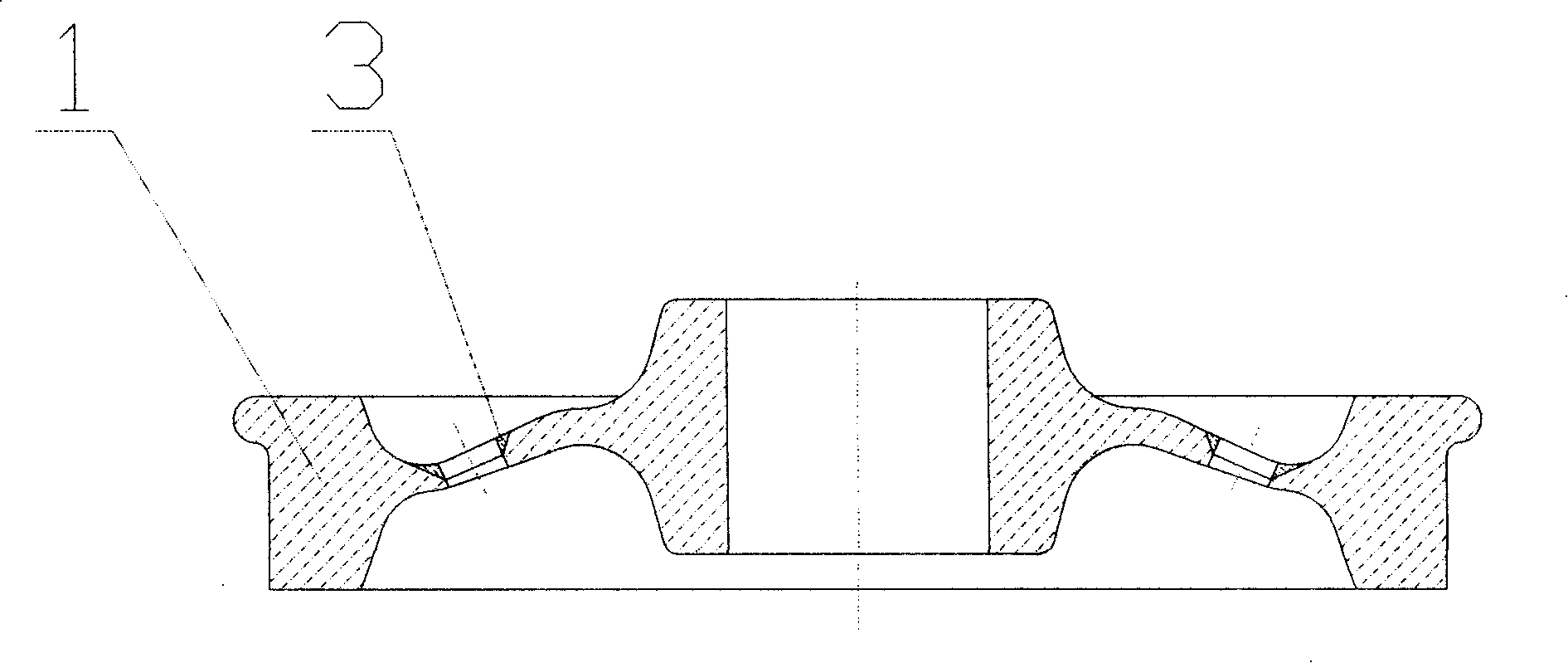

[0031] Example 2 Repair reinforced wheel with annular reinforcement

[0032] The structure of the repaired reinforced wheel with annular reinforcement is such as figure 2 As shown, it consists of a railway wheel 1 and an annular reinforcement 3 . The annular reinforcement 3 is inserted into the web hole of the railway wheel 1 . The material of the railway wheel 1 is medium carbon alloy steel, and the material of the annular reinforcement 3 is a nickel-based alloy higher than the base material.

[0033] The strength and toughness of the nickel-based alloy are higher than those of the medium carbon alloy steel, so the comprehensive performance of the railway wheel 1 after the repair is improved.

Embodiment 3

[0034] Example 3 Repair process for repairing reinforced wheels

[0035] ①Crack detection.

[0036] ②Crack cleaning, including beveling with a beveling machine for wheelset wheel repair,

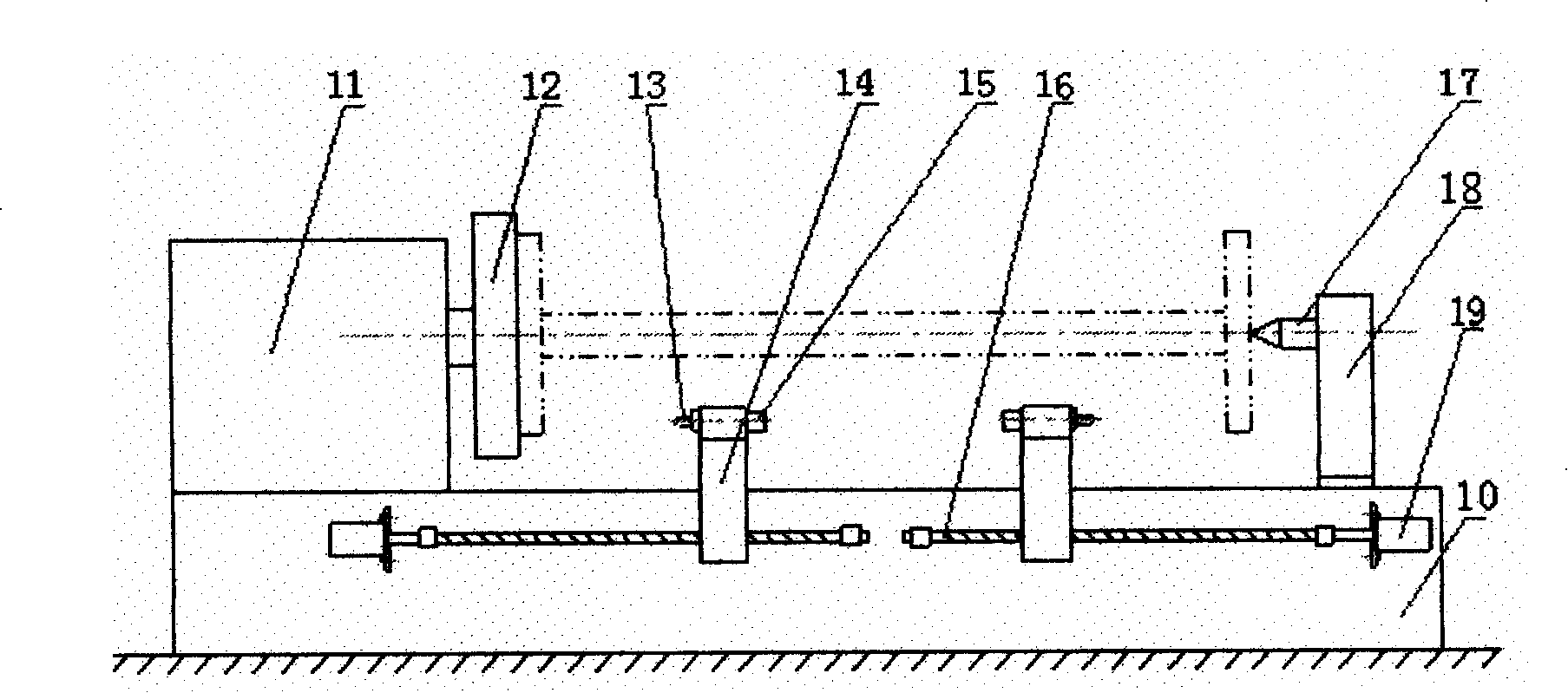

[0037] The structure of the beveling machine for wheelset wheel repair is as follows image 3 As shown, it is composed of a bed 10, a headstock 11, a chuck 12, a center 17, a tailstock 18, a tool rest 14 and a lead screw 16. The bed 10 is equipped with a headstock 11, a tailstock 18 and a lead screw 16. , the chuck 12 is mounted on the headstock 11, the top 17 is mounted on the tailstock 18, the tool post 14 is mounted on the lead screw 16, the lead screw 16 is driven by a separate motor I 19, and the milling cutter is installed on the tool post 14 13. Driven by motor II15, there are two sets of motor I19, lead screw 16, tool post 14, milling cutter 13 and motor II15. One milling cutter 13 faces the chuck 12 and the other milling cutter 13 faces the tailstock 18.

[0038] The wheel set is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crack length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap